GIW Industries recently helped improve efficiencies at the Kinross Fort Knox mine in Fairbanks, Alaska. The installation of two MDX slurry pumps nearly doubled the wear life of the pump wet ends and cut maintenance downtime in half.

Located within the Fairbanks mining district — one of the largest gold-producing areas in Alaska — the Kinross mine at Fort Knox operates year round, seven days a week, processing high-grade ore at a daily capacity of 45,000 tons per day. As a result, the Fort Knox mill requires its pumps to be up and running reliably. However, maintenance required on its previous slurry pumps meant stopping a portion of the production process for up to half a shift.

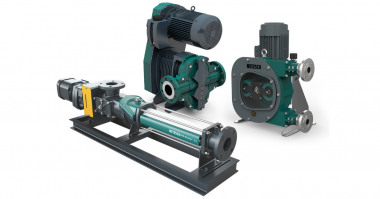

MDX slurry pumps have two critical improvements that extend the service life of the pump:

Lower Specific Speed Design: A large-diameter impeller allows for slower pump operation that extends wet-end parts wear life, even under variable flow conditions.

Slurry Diverter: This exclusive technology dramatically increases suction liner life by reducing particle recirculation between the impeller and liner.  The diverter is based on the theory that if particle contamination can be excluded from the nose gap, wear life can be dramatically improved.

The diverter is based on the theory that if particle contamination can be excluded from the nose gap, wear life can be dramatically improved.

Research has shown that internal velocity and pressure gradients between the impeller shroud and the pump casing can allow particles to migrate toward the suction eye. These solids contribute to the wear induced degradation of the gap between the suction liner and the impeller. As this gap grows, wear rates increase and pump efficiency is reduced

Lab testing has been used to verify the particle flow and develop different solutions to

counter it. By “diverting” particles away from the casing wall, their flow direction could be reversed. The result is the patented Slurry Diverter design. The patented features of the Diverter design combine to significantly extend the average service life of the pump while processing the same amount of ore.

In addition, the MDX’s Adjustable Suction Liner simplifies the process of making routine adjustments that are critical for extending pump service life.

“In the old days, making critical adjustments meant taking the pump out of service, and customers simply don’t have the time or the personnel to do that anymore,” said Ben Altman, Northern Regional Sales Manager of GIW. “Perhaps the most exciting feature of the MDX pump is the adjustable suction liner. Customers actually look forward to making adjustments with this pump because it’s so easy to do.”

Pump adjustments can now be done without taking the pump out of operation. Fewer unscheduled outages and increased uptime has translated into more efficient production and greater profits.

As a subsidiary of KSB AG of Germany, a global pump and valve manufacturer, GIW and KSB can offer over 150 years experience in pumps and hydraulics.

Comments