Contributor: Cody Kauffman, SEPCO

When did P3 Dynamics join the Sealing Equipment Products Company (SEPCO) family?

P3 joined the SEPCO family in March 2016 after having SEPCO as a client for several years. (Note: Today, P3 Dynamics is the plastics product division of SEPCO that produces the high-performance polymer line.)

When was P3 Dynamics founded?

P3 was founded in 2012 by Louie Trenado, me, and another partner. At the time, we had, combined, more than 70 years of experience in the polymer processing and machining industry. We wanted to offer a level of technical and customer service that was unmatched in the industry.

Why did you get involved in the plastics industry?

I had the opportunity to get involved in the industry early in my college years because I had family in the business. This is a very unique and rewarding industry, and as a result, I’ve never looked back and never wanted to leave … working with such great people like the SEPCO crew certainly doesn’t hurt.

What are the main compounds that P3 Dynamics produces?

We specialize in materials with PTFE, PPS, and PEEK as the base polymer. From those bases, an extraordinarily large number of materials are produced. We compound with industry standard fillers (such as glass fibers, carbon, graphite, bronze, and stainless). We also produce custom-engineered compounds for specific applications.

What are the major industries in which the products are used?

At our core, we are a sealing company. Our products are found in applications that involve fluid handling and movement. Some industries include chemical transportation, oil and gas, food processing, mining, pulp and paper, and hydraulic systems.

What are some of the ways in which the molded shapes that P3 Dynamics provides are produced?

P3 provides three main product groups, the first of which is unfinished powder materials. With our state-of-the-art, high-intensity blenders, we mix products to customers’ specifications or to perform in a particular application. These products are then molded/machined by the customer themselves

The second way we supply products is in semi-finished forms. This would be material molded into rods or tubes that are ready for machining. We can mold up to a 15-inch diameter and up to a 10-inch length. These semi-finished pieces can be made up of standard materials or virtually any other base or filler the customer requests. We sell products in an array of industries—such as cosmetics, farming and agriculture, food processing, and semiconductors. However, our core business is industrial applications such as:

- Pumps

- Valves

- Hydraulic systems

The third product group we supply is finished machined parts.

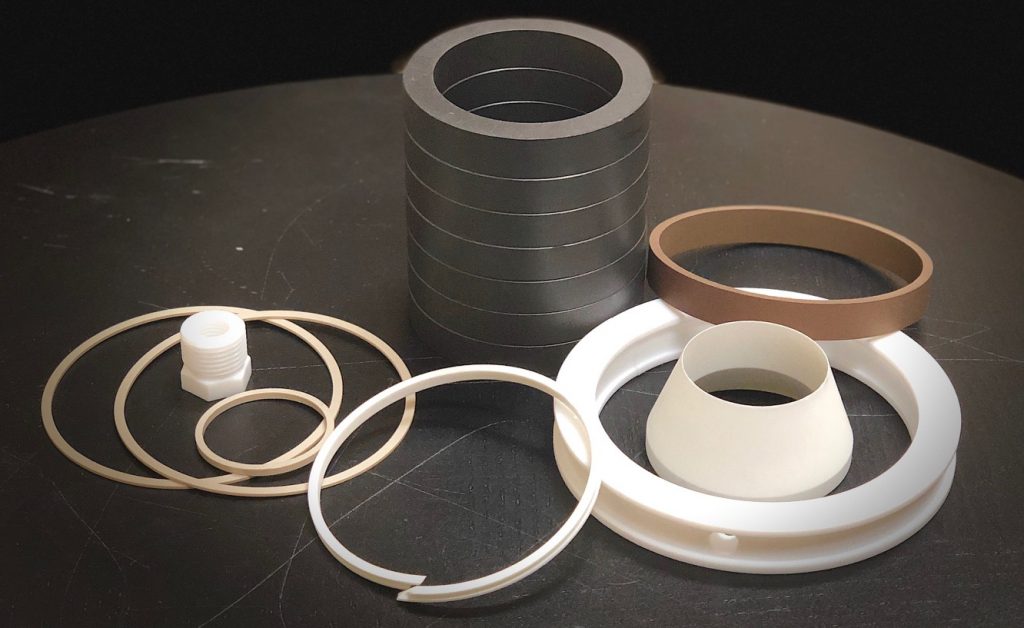

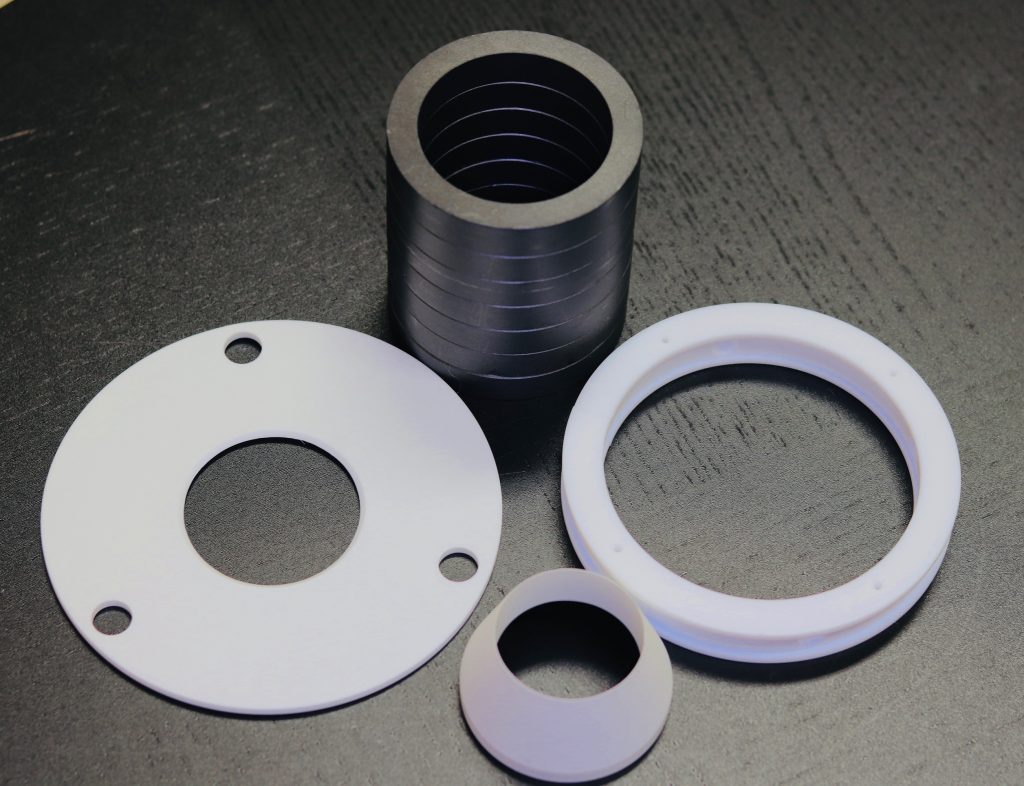

Lantern rings, gaskets, and lip seals are a few of the components manufactured by P3, the plastics division of SEPCO.

What types of machined parts does P3 Dynamics manufacture?

It may be easier to answer what we DON’T machine… which is almost nothing. We have CNC capabilities in both turning and milling and also have experienced machinist who can produce virtually anything. That being said, we regularly machine things like:

- Chevron v-sets

- Soot blower sets

- Split backup rings

- Lantern rings

- Clamp plate gaskets

- Flange gaskets

- Envelope gaskets

- Ball valve seats and repair kits

- Lip seals

- Spring energized seals

- The SEPCO HydraLoad

Anything else readers should know about P3 and/or its products?

P3 Dynamics has always prided itself on being a customer service company. That sounds very cliché, but for us, it’s true, it’s real, and it’s one of the reasons our partnership as a SEPCO business unit has been such a great fit. We want customers to feel good about talking with us, to make their experience a pleasure and a joy. If you need a partner and a friend who is also your supplier, we want to be that for our customers. Let us find a way.

http://test.empoweringpumps.com/products/sepco-air-seal

![Durlon Chemap® filters solve filtration tasks in a simpleand economic way [Case Study]](http://test.empoweringpumps.com/wp-content/uploads/2022/12/Durlon-Chemap®-filters-solve-filtration-tasks-in-a-simpleand-economic-way-Case-Study-7-380x199.png)

Comments