Suction is often defined as a force that causes a fluid or a mixture to be drawn into an interior space. Some dictionaries more accurately define suction as a force or condition produced by a difference of pressures. Both definitions are correct. However, the first tends to support the illusion that suction is the action of pulling or drawing in. Pumps do not operate on illusions. So let’s take a look at what suction really is.

One’s own observation of sucking through a straw agrees with the apparency that suction occurs all at the receiving end. The difference in pressures between the suction apparatus, your mouth, and the external glass of liquid into which the straw is inserted, is not observed. The surrounding air pressure is acting against the surface of the liquid in the glass, pushing it into the straw. Air pressure is omni-present, but it’s invisible.

The classic elementary school demonstration of this principle is the glass of water, overturned with a paper card covering the lip at the bottom magically holding the water up inside. Upon first witnessing this I was sufficiently impressed that I repeated the experiment several times myself. I somewhat recall being taught that this phenomenon was caused by air pressure but I considered it was actually due to the pull of vacuum in the void space at the top.

In a way, air pressure is like gravity – it is everywhere. But even though both of these natural phenomena are invisible, people tend to recognize gravity and have a concept of its relationship to weight. Gravity is a scientific phenomenon taught in school and, importantly, it is a word commonly used to describe our experiences with it. We overcome ‘gravity’ to rise out of bed; a rider coasts downhill and lets ‘gravity’ do the work. Most of us tend to associate ‘air pressure’ with something other than the medium which surrounds us, for example, filling up a tire. Except for meteorologists, people tend to consider the conditions of vacuum or suction as some sort of negative force and not as a positive force from atmospheric or system pressure.

The word suction, along with its commonly understood definition, focuses attention on the apparatus that reduces pressure. Suction is actually a condition of two pressures relative to one another. One condition is the reduction of pressure at the apparatus. The other condition is the higher pressure upstream or external to it.

Why does this matter? If one is involved in designing pumping systems and selecting pumps, it is important to understand the essential attribute and performance limitation of a pump – its suction capability.

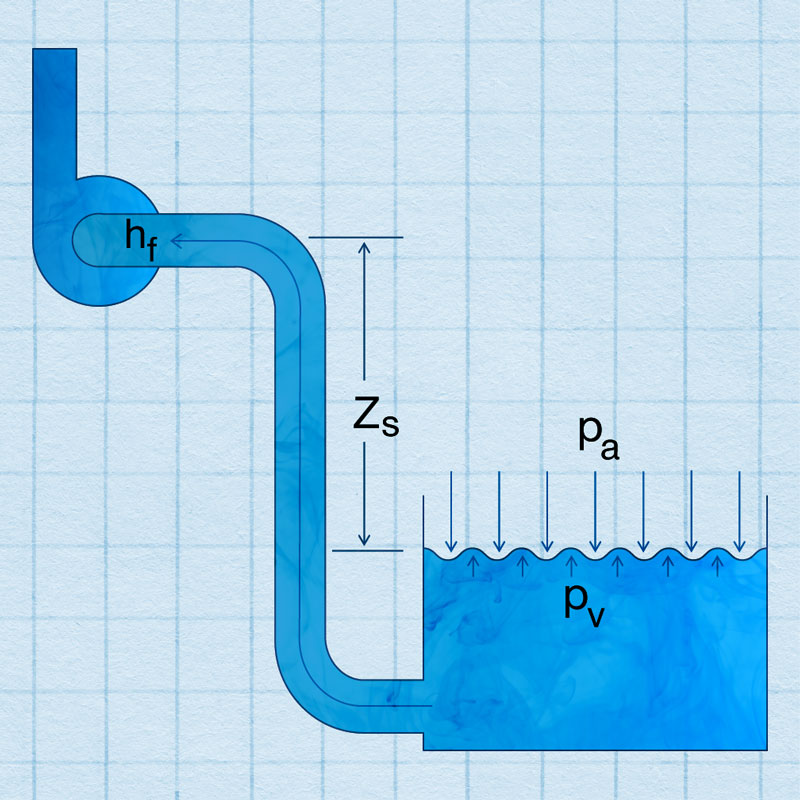

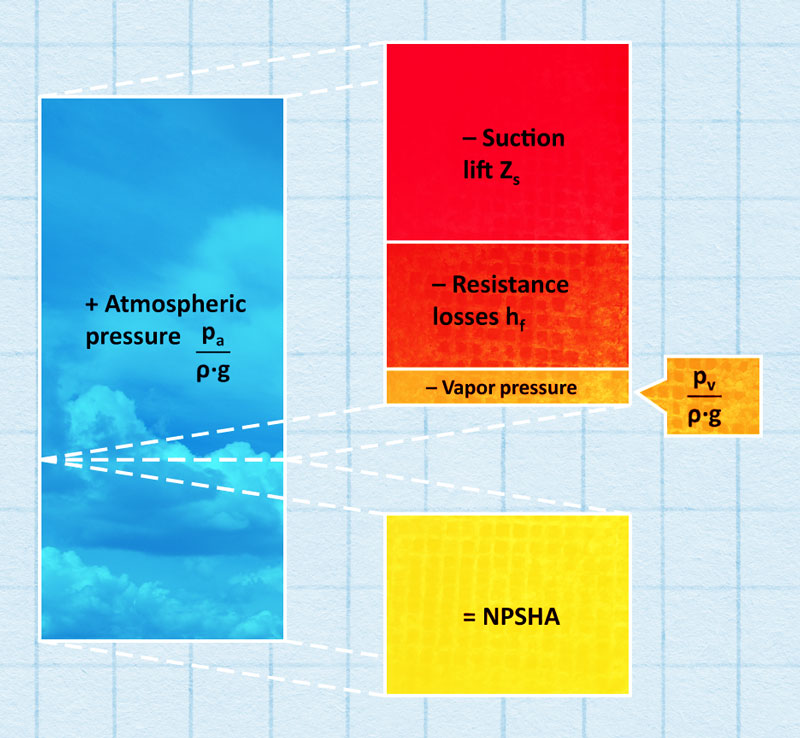

Take the case of a pump located above the liquid source. In this arrangement, a pump can achieve only so much suction ‘lift,’ the vertical distance from the liquid surface up to the suction nozzle. The limitations of pumping lift, imposed by the properties of water and of atmospheric pressure, were not understood until the mid-17th century. For two millennia, men of philosophy and science accepted Aristotle’s idea that “nature abhors a vacuum.”

In the year 1641, pump-makers commissioned by the Grand Duke of Tuscany failed to achieve the required pumping lift for a showcase fountain project. Even though they had never previously achieved a pumping lift of greater than 32 feet (10 m), they were yet persuaded by the Grand Duke to build pumps to accomplish a lift of some 50 feet (15 m) or more. After all, Aristotle’s hypothesis had not been disproven. However, their best efforts were doomed to fail by attempting to exceed physical limitations imposed by nature. The esteemed and venerable Galileo Galilei was summoned for his advice on what was perhaps the earliest recorded pump suction performance trouble job. Ultimately and wisely he suggested that although nature abhorred a vacuum, yet she did not abhor a vacuum greater than thirty-two feet (10 m) of water.

Among the several students and scientists who sought to understand the pumping lift problem was Evangelista Torricelli. He eventually experimented with a long glass tube evacuated at the top and could raise a column of water to no more than 32 feet (10 m). He then reasoned that if a mercury column rose to a lesser height, in inverse proportion to its density relative to that of water, this would prove that atmospheric pressure provides the force that holds up the liquid, and not the vacuum at the top of the tube. Torricelli wrote “Noi viviamo sommersi nel fondo d’un pelago d’aria” (We live submerged at the bottom of an ocean of air) and so it was that he was the first to understand this physical phenomenon.

Thus today we understand the limitations of lifting water from a source open to the atmosphere. But what about pump intake in a closed conduit pumping system? In that arrangement the pump suction nozzle, say, is subjected to an absolute pressure sufficient to retain the pumped product in a liquid state. The pump either dynamically, with a centrifugal type, or by change of volume, with a displacement type, creates a zone of reduced pressure at the suction end. But the liquid is not ‘sucked.’ Apart from capillary and surface effects, a liquid does not sustain tension. Rather, it is ‘pushed’ by greater upstream pressure through the piping and into the pump. A closed conduit system permits a wide range of possible pump intake conditions, not limited by atmospheric pressure.

To understand the fundamental limiting condition for pump suction performance, the effects of pressure and temperature on the phases of liquid and vapor must be introduced. Specifically, at a given temperature of liquid, there is a pressure, known as the vapor pressure, below which a liquid changes suddenly into vapor. In the mid-19th century, some two hundred years after Torricelli’s experiments, engineer- physicist Benoît Paul Émile Clapeyron and mathematician-physicist Rudolf Clausius established the essential phase relationships of gases, liquids and solids and, in particular for pumps, the liquid-vapor phase properties. These, along with Bernoulli’s principle relating velocity and pressure, published in 1738, are what define the limiting suction characteristic for a pumping system.

Knowledge of these physical properties led to the now-familiar pump parameter ‘Net Positive Suction Head.’ The NPSH at a given location in the system can be thought of as the height of liquid in a column just before the ‘vacuum’ void at the top forms as the liquid flashes to vapor.

Engineers familiar with pumps know that when we speak of suction or of ‘vacuum’ we are speaking of a relative difference in pressures. Flow and vapor pressure also come into play. So, depending upon your familiarity with these concepts, suction is not necessarily what you think it is.

For an independent evaluation of system or pump suction performance, contact an experienced consulting engineer who can help with your specific application.

Comments