Scenario

Many Malaysian offshore oil and gas production platforms with gas lift/gas injection applications experience problems related to reduced flows as gas fields decline. On one platform, the operator called Cook Compression to assist their technical services group in assessing the mechanical reliability and performance potential of an Ariel JGK-4 reciprocating compressor. Their goal was to optimize compression to meet new flow requirements in the face of changing process conditions.

The compressor is lubricated and has four throws, four double-acting cylinders and three stages. Each of the four cylinders has a variable volume clearance pocket (VVCP) installed on the head end. The driver is a Caterpillar G3606TA natural gas engine rated at 1,775 hp [1,324 kW] @ 1,000 rpm and 1,600 hp [1,194 kW] @ 900 rpm. Both compressor and engine run at 900-1,000rpm.

The compressor is lubricated and has four throws, four double-acting cylinders and three stages. Each of the four cylinders has a variable volume clearance pocket (VVCP) installed on the head end. The driver is a Caterpillar G3606TA natural gas engine rated at 1,775 hp [1,324 kW] @ 1,000 rpm and 1,600 hp [1,194 kW] @ 900 rpm. Both compressor and engine run at 900-1,000rpm.

Solution

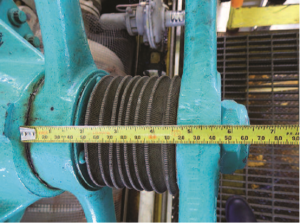

The Cook assessment included a complete asset analysis and vibration study by Windrock Technical Services. The team determined that customer objectives could be met – using their existing equipment – by fine-tuning the cylinder clearance. This would be accomplished by adjusting the VVCP through sizing performance at different load steps.

The Cook assessment included a complete asset analysis and vibration study by Windrock Technical Services. The team determined that customer objectives could be met – using their existing equipment – by fine-tuning the cylinder clearance. This would be accomplished by adjusting the VVCP through sizing performance at different load steps.

After preparing VVCP adjustment and step-by-step unloading procedures, a Cook representative supervised the procedure. Since the unit was scheduled to be off-line for maintenance,it was not necessary to make progressive adjustments to gradually load the unit.

After preparing VVCP adjustment and step-by-step unloading procedures, a Cook representative supervised the procedure. Since the unit was scheduled to be off-line for maintenance,it was not necessary to make progressive adjustments to gradually load the unit.

Results

Balancing the gas load between the three stages of the compressor allowed for additional loading of the engine. The net result was a 0.5–0.8 mmscfd increase in flow (6 to 10%). It was determined that an additional flow increase of approximately 0.2 mmscfd could be achieved by increasing the engine speed by approximately 50 rpm.

Increasing the capacity of the unit also improved overall process reliability. Because the compressor operates in parallel with two compressors on a second platform,the flow increase enabled objectives to be met using two compressors, allowing the third unit to be used in standby mode.

The collaborative efforts of Cook Project Engineering and Windrock Technical Services allowed the customer to meet performance objectives and assure the mechanical condition of their machinery with minimal cost and disruption to their operations.

For more details about Cook Project Engineering, contact your Cook Compression representative or visit cookcompression.com.

Comments