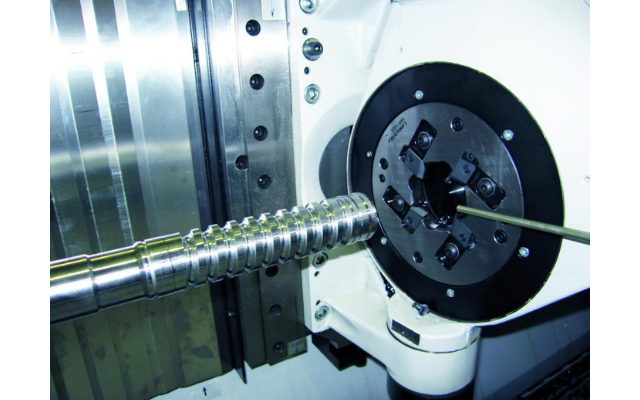

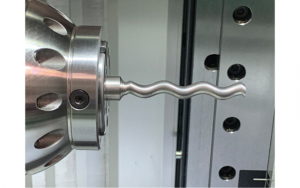

As the only U.S. based source of thread whirling tools and machines, Leistritz uniquely combines leadership in this innovative technology with an extensive background in machining solutions for traditional screws, worms, extruders and augers. Utilized by itself, whirling can be used for cutting threads, screw forms, worms, etc. When integrated with other techniques, it creates a rich spectrum of total solutions. This could include incorporating whirling with milling, grinding, turning as well as material handling via automated systems.

Why Select Whirling?

Possibility to reduce or even eliminate expensive grinding operations

Improved cycle times, up to 3 times faster!

Precise thread profile accuracy, repeatability, and surface finish

Rapid tool set-up and workpiece handling

Eliminate costly disposal of environmentally hazardous cutting fluids and coolants

Environmentally friendly compared to conventional milling and grinding

Leistritz’ easy-to-use tooling system combined with the benefits of faster cycle times and surface finish quality, prove that whirling is today’s most economical and cost-effective solution to produce precise threaded parts. Leistritz Machine Tools offer cost effective options for highly demanding and sophisticated manufacturing tasks. Our tools are characterized by high precision, flexibility and state of the art performance. Leistritz’ Whirling Machines are designed to produce optimal results, with a high degree of automation with a large selection of Whirling Machines for both internal and external thread whirling.

Comments