Forward thinking operators like Statoil and Total envision the complete ‘subsea factory’ by 2020. To make this vision a reality, a keynote operator panel has been assembled at the Subsea Processing and Flow Assurance Conference (Houston, May 26-27) to review the business case for subsea processing and flow assurance.

Unlock the ‘Subsea Factory’ strategy topics here

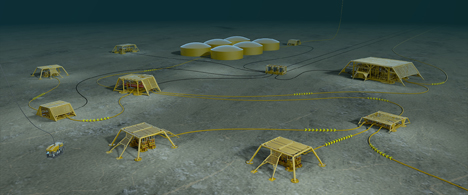

So why is this such a big deal? Well, imagine a ‘subsea factory’ (process plant) on the seabed that makes it possible to utilize remote-controlled transport of hydrocarbons at any offshore facility. This completely removes the need for mega topside facilities and is the key to tapping into challenging deep water oil and gas reserves around the globe.

The advanced subsea processing technology required to make this possible will bring about cataclysmic change to the oil and gas sector, completely transforming the production process. But there is still some way to go.

Industry collaboration is already under way this year with 200+ subsea processing and flow assurance experts expected to attend the Subsea Processing and Flow Assurance Conference in Houston.

Key operators, EPC’s and Subsea Contractors will gather to:

- Explore the vision behind moving the entire processing system to the seafloor as a way to maximize production and cut CAPEX and OPEX costs

- Discuss both the positive and negative impacts that low oil prices will have on the development of subsea processing

- Understand the importance of cross-industry collaboration, standardization and technology qualification to guarantee subsea factories will become a reality

For more info please visit http://www.upstreamintel.com/flow-assurance/

Comments