To meet the growing need for protection against electrical discharge machining (EDM), Inpro/Seal has updated and expanded its portfolio of shaft grounding solutions. Smart Shaft Grounding from Inpro/Seal combines proven Current Diverter Ring® technology with innovative new features to increase reliability and decrease maintenance costs. The use of variable frequency drives (VFDs) continues to expand due to their ability to reduce energy consumption and generate significant cost savings, but VFDs also induce high frequency voltages on the shaft that can damage bearings as they seek a path to ground. With the Smart Shaft Grounding product portfolio, Inpro/Seal increases motor reliability by providing voltages a low impedance path to ground away from the bearings while monitoring grounding effectiveness.

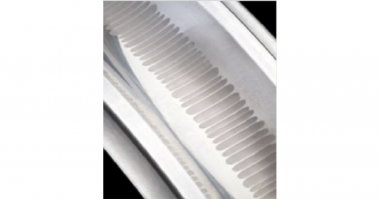

The Smart Shaft Grounding product portfolio, consisting of the Smart™ CDR® , Smart™ MGS® and Smart Ground Monitor™, addresses key limitations of existing shaft grounding technologies. Most notably, Inpro/Seal Smart Shaft Grounding provides permanent protection from conduction-inhibiting shaft oxidation and offers continuous monitoring and feedback of shaft grounding performance. With proprietary conductive filaments and an innovative bearing-bronze sleeve design, the Smart CDR outperforms and outlasts other grounding rings. The Smart MGS integrates Current Diverter Ring technology and the patented VBXX® Bearing Isolator to protect against contamination ingress and lubrication loss as well as stray currents. Isolated conductive filaments and a zero-maintenance conductive bronze rotor – unique to Inpro/Seal – provide premium connectivity in harsh conditions.

To further ensure reliability and provide peace of mind, the Smart Ground Monitor alerts users in real time of non-optimal contact between the filaments and shaft. Contact is measured through the Smart Terminal that comes standard on every Smart CDR and Smart MGS. Smart Shaft Grounding solutions meet NEMA MG1 31.4.4.3 and CSI 23 05 13 specifications and are available in standard sizes or custom engineered solutions.

For more information about Inpro/Seal Smart Shaft Grounding solutions, visit www.inpro-seal.com.

About Inpro/Seal

The inventor of the original Bearing Isolator, Inpro/Seal® has been delivering innovative sealing solutions and outstanding customer service for more than 30 years. Their unique technologies increase the reliability of rotating equipment and provide real cost savings by improving the mean time between repair (MTBR). Inpro/Seal’s superior customer service and streamlined production processes allow for same- or next-day shipments on most products, even new designs. Headquartered in Rock Island, Ill., USA, Inpro/Seal maintains a global sales and distribution network to provide responsive, localized support to customers worldwide and manufactures in North America, South America, Asia and Europe. Inpro/Seal is a Waukesha Bearings® business. Waukesha Bearings is an operating company of Dover. Additional information is available at www.inpro-seal.com.

About Dover

Dover is a diversified global manufacturer with annual revenues in excess of $7 billion. Dover delivers innovative equipment and components, specialty systems and support services through four major operating segments: Energy, Engineered Systems, Fluids, and Refrigeration & Food Equipment. Dover combines global scale with operational agility to lead the markets they serve. Recognized for their entrepreneurial approach for nearly 60 years, Dover’s team of over 26,000 employees takes an ownership mindset, collaborating with customers to redefine what’s possible. Headquartered in Downers Grove, Ill., USA, Dover trades on the New York Stock Exchange under “DOV.” Additional information is available at www.dovercorporation.com.

Comments