Out-gassing is a scenario where a fluid enters a pipe as a liquid and exits as a liquid and gas. While it might sound identical, this is a separate occurrence from flashing and will be explained in this article.

Flashing is where a pure fluid’s (eg. water) pressure falls below the vapor pressure. The liquid absorbs heat and starts a phase change into a vapor. Flashing is relatively easy to predict because it can be modeled by the ISA/IEC Liquid Sizing Equations.

Out-gassing differs from flashing because there are multiple constituents in the flow stream. So, it will not have the same characteristics as a pure fluid. In out-gassing a pressure drop will cause the gas to come out of the liquid mixture. All of this happens relatively quickly compared to flashing. Unlike flashing, the ISA/IEC sizing equations do not accurately account for out-gassing. Emerson’s Fisher research engineers have developed a proprietary technique for addressing the range of Cv’s that out-gassing can produce. A great real world example of out-gassing is a soda can. The gas is compressed with the liquid in the can. When the lid is popped, the gas escapes quickly because of the sudden drop in pressure.

Out-gassing generally causes two types of damage. One type of damage occurs due to the high velocity jets coming out of solution, which carry small liquid particles. These liquid particles impinge on internal surfaces at very high velocities causing erosion damage. Secondly, the high velocity jets coming out of solution tend to impinge on the body wall and trim parts causing vibration. The jet size is determined by the size of the cage hole/window through which the fluid flows. Breaking up the large jets into smaller jets helps to prevent vibration, as well as damage from entrained particulate.

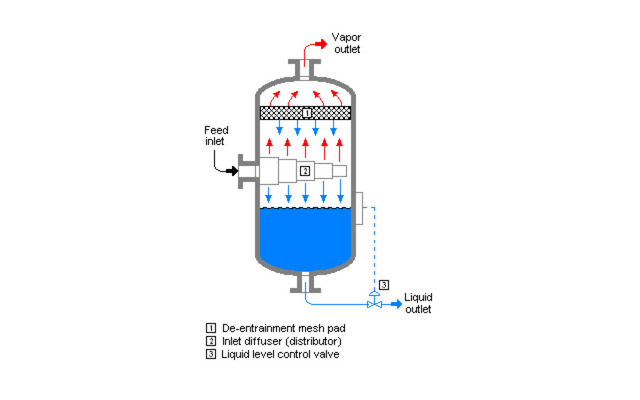

The most severe out-gassing application is separator letdown service. For this demanding application, a Fisher DST-G [dirty service trim for out-gassing applications] trim uses a different component in place of the lower cage. The slotted lower cage design facilitates smaller jet formation as the jets discharge from the cage into the body expansion area. By separating the jets, damage is prevented by forming many smaller jets that contain far less energy. The large slotted design also allows particles up to ¼ inch in size to pass through the trim, reducing problems associated with plugging.

The DST-G block forged valve body uses an expanded body cavity that allows the entrained gases to expand. This expansion reduces the damaging effects of the previously mentioned high velocity jets. The protected seat design also allows the shutoff function of the valve to be separate from the throttling areas of the trim.

To discuss your application, contact your local Emerson sales office.

Comments