GPM Pump & Seal reduces initial purchase cost with one-size-smaller couplings when using TB Wood’s Sure-Flex® Plus sleeves.

New Sure-Flex® Plus enhanced EPDM and Neoprene sleeve materials yield a 30 percent increase in torque ratings compared to previous sleeves.

Located in the greater Houston area, GPM Pump and Seal is a premier provider of high-quality pumps, pump parts, mechanical seals and complete pump systems for various applications including oil and gas, petro-chemical, mining, water and wastewater treatment. They also specialize in pump and mechanical seal repair for all major OEMs.

GPM prides itself on understanding and responding to their customers’ needs as explained by Jon Boultinghouse, Sales & Operations Manager at GPM: “With Oil and Gas where it is, along with the rest of the market, we see a growing trend with customers focusing on cost and value. They still need to operate, but are being forced to operate on smaller budgets.”

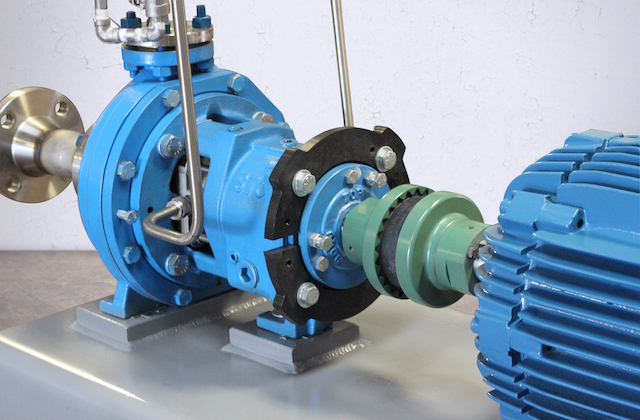

Elastomeric couplings are the industry standard for GPM’s market. Most of their customers are familiar with them and prefer their ease-of-use. Elastomeric couplings can accommodate moderate misalignment that inevitably occurs in real-world applications due to pipe strain, thermal loads, settling baseplates, and various other causes.

GPM had started specifying TB Wood’s Sure-Flex® couplings several years ago. “Early-on, we used a decent amount of competitor couplings. But eventually we went with TB Wood’s because of the quality and value of their Sure-Flex coupling along with the positive image they have in the market,” Boultinghouse explained. “We routinely replace competitor couplings in the field. Customers often have issues with burs and shaft bores on some of the lower-quality competitor brands. Once they use a TB Wood’s coupling on the same application, and see how well it fits on their equipment, they never go back.”

TB Wood’s recently introduced the Sure-Flex® Plus coupling, making the industry-favorite Sure-Flex couplings even better. New elastomeric sleeves provide higher performance and enhanced durability due to significant improvements in proprietary EPDM and Neoprene materials.

“We met with the GPM team to discuss the real-world benefits of our new EPDM and Neoprene sleeve materials. Our improved rubber compounds offer a 30% increase in torque ratings when compared to previous sleeves and competitors offerings,” said John Smihal, Product Manager – Elastomeric Couplings at TB Wood’s. “This performance improvement allows many applications to use a smaller size coupling at an average 25 percent cost savings.”

Application Example:

20 HP at 1750 RPM, 1.625” x 1.375” shafts

Original Sure-Flex Coupling Selection: Size 8S

New Sure-Flex Plus Coupling Recommendation: Size 7S

List Price savings: 25%

Sure-Flex Plus couplings provide exceptional torsional flexibility, while the 4-way flexing action absorbs virtually all types of shock, vibration, misalignment and end float.

The couplings feature 7° to 21° torsional wind-up (depending on sleeve material), torque ratings up to 8,20 kNm (72,480 in.lbs.), and fast and easy installation. Units require no lubrication and no maintenance. Spacer, bushed hub and clamping hub designs are always in stock for fast delivery.

Extensive testing validates improved performance and long life

Recently conducted low-cycle fatigue testing demonstrated that proprietary Sure-Flex Plus polymeric sleeves outlast common competitors by more than three times, while wear testing showed Sure-Flex Plus sleeves demonstrated significantly less wear on the rubber teeth compared to common competitors during accelerated high misalignment and low-load testing.

Development testing also confirmed that the new proprietary EPDM and Neoprene rubber sleeves enable a 30% increase in the torque rating when compared to the previous generation sleeves and similar offerings by competitors.

Sure-Flex Plus couplings: The right fit for GPM

“We use couplings on almost all of our pump applications. Picking the right size is important,” said Boultinghouse. “A balancing act is required to size the coupling large enough, with enough service factor to work effectively, but also not too large as to incur unneeded cost, like larger guards, skids or baseplates.”

GPM quickly standardized on the new TB Wood’s Sure-Flex Plus coupling line for use on many of their custom pump assembly packages. “For us, the choice was easy. Competitive price, highest quality and increased torque rating,” Boultinghouse explained.

GPM uses TB Wood’s Sure-Flex Plus couplings on all the non-close-coupled pump units they build. The most significant impact of the new couplings is on their ANSI pump packages. The ability to drop-down a coupling size often gives them the edge they need to compete on large projects.

“We now stock many Sure-Flex Plus coupling sizes for most of our applications, but it is reassuring to know that TB Wood’s can quick-ship almost anything in case we need a non-stocked item,” Boultinghouse said. “We also like the assurance we can give to our customers that our packages utilize the absolute best coupling on the market.”

GPM customers reap the rewards

One other major Sure-Flex Plus benefit they’ve noticed is with their smaller Group 1 ANSI pump packages. These configurations typically have a short pump shaft along with clearance issues associated with some types of labyrinth bearing seals.

“These conditions make it difficult to remove the coupling’s center sleeve element while performing a motor bump test. This is especially challenging when a larger horsepower motor is used, that requires a larger coupling,” Boultinghouse explained. “Dropping down to a smaller size coupling is a huge benefit for our customers, especially maintenance operators.”

According to Boultinghouse, “The most significant overall advantage of using the Sure-Flex Plus coupling is the simple fact that it is more economical, more reliable and can handle more torque than its competitors. If a customer can increase Mean Time Between Failure (MTBF), or utilize a smaller more cost-effective coupling on a new application, they will.”

In a market as competitive as this one, any savings acquired by GPM are passed along to the customer to keep their pricing as competitive as possible. So in the end, the customer is the real beneficiary.

“Also, offering a coupling that lasts longer in our packages helps give our products a reputation of robustness and quality,” he said. “Having a reputation like that is invaluable.”

Sure-Flex Plus sleeves are 100 percent interchangeable with existing flanges, supplying a true “drop-in” performance improvement. With a 30 percent torque rating increase, the enhanced EPDM and Neoprene sleeves not only allow coupling users to replace their competitive couplings with one-size-smaller Sure-Flex Plus couplings, but also provide a more rugged, longer life replacement sleeve that fits in the flanges of Sure-flex couplings and competitive products currently in service.

Comments