Contributor: Watts Water Technologies

The water industry’s successful efforts in developing standards for water quality have made potable water a public right and expectation. Water flowing from a faucet, whether commercial or residential, is expected to be clean and safe. As water professionals, we are responsible for maintaining these standards and continuing to provide communities with safe, potable water. Despite our best efforts, there will always be an underlying threat to these safety standards, coming in the form of backflow. Plumbing cross-connections constantly put our water system in danger of contamination, and without proper backflow prevention systems in place, contaminants can easily enter our water supply. However, many backflow preventers come with their own risk – flooding from relief valves. Let’s look at how we protect our water supply, the equipment in our water distribution systems, and our buildings that we need to maintain responsibly. Let’s start with backflow…

What is backflow?

Backflow is the unwanted and potentially dangerous reverse flow of liquid, gas, or another substance into a potable water distribution system. Due to the complex and unique nature of each plumbing system, backflow problems are typically not identified until serious symptoms arise. According to the EPA, “most backflow incidents are generally detected and reported to the local authority only if customers detect an irregularity in their water supply…but not all contamination that produces illness and disease can be detected by taste, color, or odor.” Even when backflow incidents are detected, some experts “suspect that there may be 10 times as many incidents as are reported,” making our responsibility to protect our communities even more relevant. So what causes backflow to happen?

Backpressure and backsiphonage are two ways in which backflow can occur. Backpressure occurs when downstream water pressure of a non-potable system surpasses the pressure of the water distribution lines containing potable water. Backsiphonage happens when normal flow is reversed because of negative or sub-atmospheric pressure in a piping system. An example is the pressure created when drinking through a straw to reverse natural flow by creating a vacuum with your mouth and the straw.

Common causes of backpressure and backsiphonage come from interruptions in the water supply that can happen in situations such as water-line flushing, firefighting events, water-main breaks, installation of heating systems, or the installation or repair of any other pressure-producing or -altering systems. Contaminants get into a water distribution system through cross-connections. A cross-connection is defined by the Environmental Protection Agency (EPA) as any actual or potential connection or structural arrangement between a public or a consumer’s potable system and any other source or system through which it is possible to introduce into any part of the potable system any used water, industrial fluid, gas, or substance other than the intended potable water with which the system is supplied. Possible contaminants range from anti-freeze in heating lines to fertilizer in irrigation systems to dirty dish water in a sink. Bypass arrangements, jumper connections, removable sections, swivel or changeover devices, and other temporary or permanent devices through which or because of which backflow can occur are considered cross-connections.

Plumbing codes mandate that potable water supplies be protected against backflow at all cross-connections. Cross-connection control to avoid catastrophic effects caused by backsiphonage and backpressure is typically achieved by utilizing backflow preventers.

What are backflow preventers?

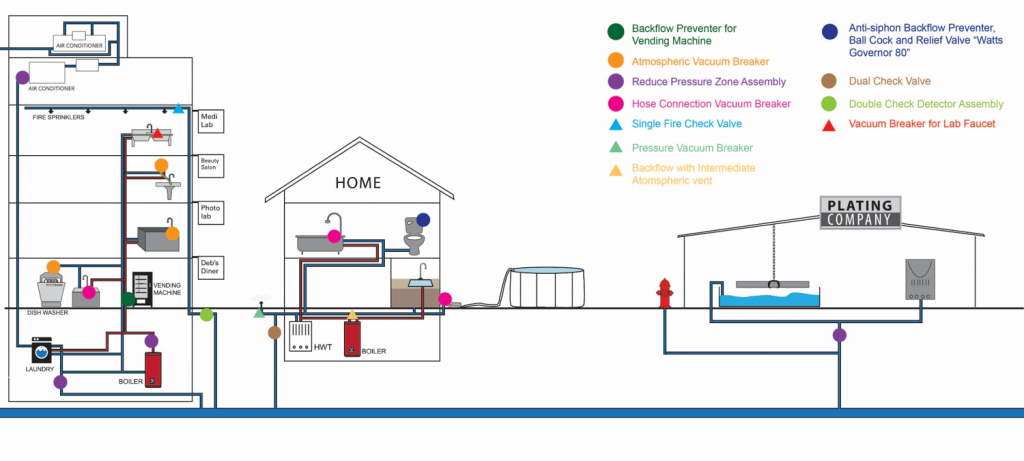

Backflow preventers are devices used to protect potable water supplies from contamination or pollution as a result of backflow (see figure 1 for ideal locations to place backflow prevention devices). In many cases, air gaps are designed into systems, allowing gravity to act as a natural backflow preventer. An air gap is an open vertical space between any device that connects to a plumbing system, like a valve or faucet, and any place where contaminated water can collect.

Backflow preventers may be installed at strategic locations within the plumbing system, and while there are several options to consider, Reduced Pressure Zone (RPZ) backflow preventers offer the highest protection of any backflow assembly. RPZ backflow preventers are an integral part of any rigorous cross-connection control program. The key elements of cross-connection control are (1) isolation protection, (2) containment, and (3) Total Backflow Protection. Isolation protects the domestic water supply at the point of use (i.e. having a backflow preventer at your hose bib or on your hydronic system). Isolation protection is typically governed by plumbing codes and local or national ordinances. Then we have containment; this is protecting the public water supply right at the source by having backflow prevention at the meter (this is typically governed by your water purveyor). Total Backflow Protection combines isolation and containment to assure safe drinking water from the point of treatment to the point of use.

A vital part of the RPZ backflow preventer is the relief valve. Unlike a typical relief valve, which relieves excess pressure caused by conditions such as thermal expansion, an RPZ relief valve is designed to open during certain backflow conditions to allow potentially contaminated water to flow out and down the drain, rather than into the potable water system. However, other causes, such as debris fouling the first check, will also cause the relief valve to discharge. While most mechanical rooms have integral drains, they are often undersized or clogged, and are unable to adequately remove water in the case of a catastrophic RPZ relief valve discharge. Because these valves are also often in basements, closets, or other less-frequented parts of a building, large and potentially costly discharge events are frequently not noticed until it is too late. Discharge rates vary based on the failure mode, model, size, and supply pressure, but can easily reach into the hundreds of gallons per minute. Flooding causes damage that is very costly to building owners – commercial flood claims on average are around $75,000, but can easily extend into the millions.

So how do you protect against flooding?

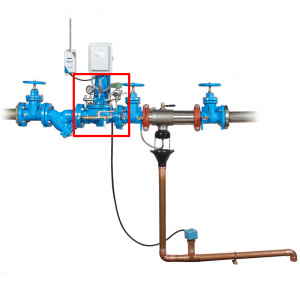

Other than designing huge drainage systems and big sump pumps into your system to help deal with the potential of catastrophic discharge, there are other tools available to mitigate flooding. There are four components of a flood detection / protection system: (1) backflow preventer (2) detection (3) shutdown (4) communication.

(1) Your backflow preventer needs to be properly installed with the manufacturer-specified air gap in the drain line. It is a common misconception that that drain line is meant to handle all potential relief valve discharge, but it’s only meant to handle the nuisance discharge from pressure fluctuations or fouling from small debris. Please make sure to avoid making that discharge into its own cross connection, and remember not to pipe that discharge line directly into the relief valve without that air gap.

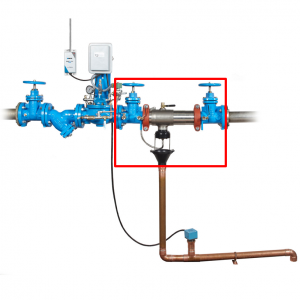

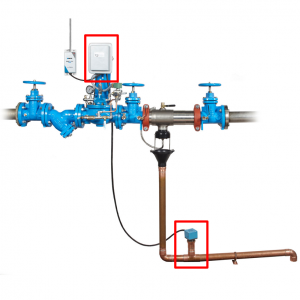

(2) Part of your flood protection plan should be the ability to detect a problem. If something is wrong and there is a potential flood about to happen, how can you detect this? There are a couple of different ways this detection can be accomplished. Notice on the bottom right of figure 3 there is a wet switch, which essentially consists of two probes looking for contact with water. If these probes are placed higher up in the discharge line, higher flow rates will set off the detection. On the other hand, if the wet switch is placed lower in the system, lower flows will set off the system alert. This can be played with and customized depending on exactly how much discharge can be handled in your application. The advantage to this kind of detection system is that it can be retrofitted to any kind of backflow preventer; you don’t need any special attachment for it to work – all you need is that discharge line. Once the switch is engaged, it needs to stay open for a pre-set amount of time before the system takes any more actions; this is to avoid any action in the case of intermittent or minimal discharge. Determine what amount of discharge can be accommodated before you need to receive an alert so that the issue can be addressed before it becomes a very expensive problem.

(2) Part of your flood protection plan should be the ability to detect a problem. If something is wrong and there is a potential flood about to happen, how can you detect this? There are a couple of different ways this detection can be accomplished. Notice on the bottom right of figure 3 there is a wet switch, which essentially consists of two probes looking for contact with water. If these probes are placed higher up in the discharge line, higher flow rates will set off the detection. On the other hand, if the wet switch is placed lower in the system, lower flows will set off the system alert. This can be played with and customized depending on exactly how much discharge can be handled in your application. The advantage to this kind of detection system is that it can be retrofitted to any kind of backflow preventer; you don’t need any special attachment for it to work – all you need is that discharge line. Once the switch is engaged, it needs to stay open for a pre-set amount of time before the system takes any more actions; this is to avoid any action in the case of intermittent or minimal discharge. Determine what amount of discharge can be accommodated before you need to receive an alert so that the issue can be addressed before it becomes a very expensive problem.

(3) Automatic shutdown is not appropriate for every application (an obvious example is a fire sprinkler system). Automatic shutdown uses an electric signal to close a shutdown valve. In the case where debris is caught in the first check valve, this automatic shutdown should stop the relief valve from discharging. Keep in mind that once the system is triggered, it must be manually turned back on; be mindful of repercussions of automatic shut off as most building occupants take issue with water being turned off and unavailable for extended periods of time.

(3) Automatic shutdown is not appropriate for every application (an obvious example is a fire sprinkler system). Automatic shutdown uses an electric signal to close a shutdown valve. In the case where debris is caught in the first check valve, this automatic shutdown should stop the relief valve from discharging. Keep in mind that once the system is triggered, it must be manually turned back on; be mindful of repercussions of automatic shut off as most building occupants take issue with water being turned off and unavailable for extended periods of time.

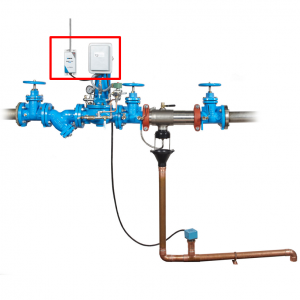

(4) The maintenance manager, building manager, or plumbing engineer needs to know when the water is shut off or if the building is flooding, so communication is critical. Communication can happen a couple of ways, one being through the BMS, or Building Management System. Sometimes referred to as a Building Automation System (BAS), this is one way to receive alerts through existing centralized infrastructure. Another way to receive notifications is through independent wireless Wireless alerts use a cellular signal, keeping important equipment off building Wi-Fi for security reasons. The only downside of this is that there has to be a cellular signal at the wireless nodes (at the place where your alert is coming from) in order to work. This is especially useful for situations where building maintenance personnel are not necessarily on the premises 24 hours a day – and we all know these catastrophic discharges tend to happen at 2 a.m. on a Sunday! The point here is to know when discharge is happening so you can prevent a major flood event.

(4) The maintenance manager, building manager, or plumbing engineer needs to know when the water is shut off or if the building is flooding, so communication is critical. Communication can happen a couple of ways, one being through the BMS, or Building Management System. Sometimes referred to as a Building Automation System (BAS), this is one way to receive alerts through existing centralized infrastructure. Another way to receive notifications is through independent wireless Wireless alerts use a cellular signal, keeping important equipment off building Wi-Fi for security reasons. The only downside of this is that there has to be a cellular signal at the wireless nodes (at the place where your alert is coming from) in order to work. This is especially useful for situations where building maintenance personnel are not necessarily on the premises 24 hours a day – and we all know these catastrophic discharges tend to happen at 2 a.m. on a Sunday! The point here is to know when discharge is happening so you can prevent a major flood event.

This is why Watt’s Water Technologies is making available to the marketplace the SentryPlus Alert™ system and the PVS-7000 Engineered Flood Protection Valve Station. The SentryPlus Alert™ system provides a comprehensive solution by detecting excessive backflow relief valve discharge, notifying the owner or operator with multi-channel alerts, and providing protection with an optional automatic shutoff valve. Learn more at watts.com/floodprotectionsystem.

Watch the Facebook Video showcasing the SentryPlus Alert™ system.

About Watts Water Technologies

For over 140 years, Watts Water Technologies has been committed to improving the comfort, safety, and quality of life for people around the world through their expertise in water technologies. Watt’s mission is simple; they want to provide high-quality products, systems, and solutions for the conveyance, conservation, control, and safe use of water. With over 50 locations around the world, Watts encourages increasing energy efficiencies and reducing waste in the process. Watts is committed to doing all they can to enable their employees, customers, and partners in the innovation, development, and manufacturing of water technologies, systems, and solutions that protect our natural resources. Because water matters.

Mitigating Reduced Pressure Zone Backflow Discharge [Webinar]

It is good to know that backpressure can cause backflow. This is important because sometimes this occurs in my home, and I could be experiencing dangerous backflow issues that I don’t even know about. I think it would be a good idea for me to get professional backflow testing and this way I can also ask the professional for tips on avoiding backpressure and other issues in the future.

It’s true that water is expected to be clean and safe in homes like mine. I think I’ll hire a contractor to install a backflow preventer in my pipes so that the potable water could be prevented. This way, the unwanted water will not go back to the water system.