Swanson Rink, Inc. was hired to design a new data center on the 29th floor of an existing high-rise data center in Los Angeles. Mechanical Engineer, Rory Heim, used AFT Fathom to determine the minimum size of the condenser water distribution pipes serving multiple data halls on the 29th floor.

Because Swanson Rink had previously designed the core building condenser water system using AFT Fathom, Heim was able to easily determine how much head pressure the building pumps (located on the 3rd floor) would be able to supply the 29th floor. Two building risers serve the 29th floor, but in this data center application Swanson Rink designed for an N+1 redundancy, so only one riser was modeled as being in operation.

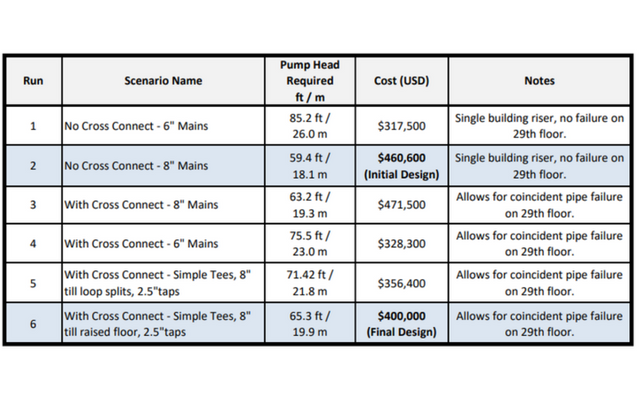

Figure 1 – Six major scenarios were evaluated using AFT Fathom’s Scenario Manager and cost calculation tool.

Heim determined the pumps on 3rd floor could only supply 65 ft (19.8 m) of head pressure to the 29th floor when only one riser is in operation.

He used AFT Fathom to model the 29th floor distribution pipes and varied the sizes of the pipes to find a combination to meet the 65 ft (19.8 m) head pressure requirement. Six major designs were evaluated (see Figure 1).

Using AFT Fathom made this task relatively simple and quick. Heim found it easy to build on past results using the Scenario Manager. Therefore, each time he adjusted the model he could create a new scenario and further modify pipes sizes while retaining the first scenario and results.

The Scenario Manager and Batch Run features allowed him to rapidly compare various scenarios and catch small differences in how certain sections of piping were performing. Color coding pipes also helped when showing the model to other engineers, as it made the layout more intuitive for others to review (see Figure 2).

Heim felt the use of fittings and losses in the pipes was invaluable as the model would have become significantly larger and cluttered with so many junctions showing. Groups were used to quickly select and change long sections of piping. He set the main loop piping into a group, as well as all of the taps from the main that served the computer room air conditioning (CRAC) units.

As a result, Heim was able to instantly change the size of all 66 pipes with a common size in the Pipe Main group in a single operation – without having to select each individual pipe each time. Same thing for the 78 pipes in the CRAC Piping group.

It was also very easy to run different emergency scenarios in AFT Fathom, as all it took was highlighting the pipes he needed to model as malfunctioning and close them with one button. Heim found closing/opening pipes was easy and appreciated that he wasn’t required to create a new scenario to “save” the results until he found results he was happy with.

Finally, AFT Fathom’s cost calculation was used to compare designs and evaluate the cost savings vs. the head pressure reductions. “I was excited to use the cost calculation on a new project. Having the ability to evaluate first cost of different designs helped inform my design direction,” said Heim.

He simply input material and installation costs for pipes and fittings used in the project to compare the different first-cost of each scenario. This allowed him to quantify the first-cost savings when going with 6” pipe vs 8” pipe, and Swanson Rink ended up saving their client 13% ($460k->400k) over the initial design.

Comments