One of North-America’s largest chocolate suppliers that strives to provide its’ customers with the highest quality products. To accomplish this, they have wisely invested in superior processing technology to perfect their craft.

Although top-of-the-line technology is in use in this particular plant, no machinery is completely infallible to breakdowns. European made chocolate holding tanks were purchased with red-rubber gaskets to seal the tank doors, as well as inside the holding tanks. Initially, the rubber gaskets worked but in time fell apart and needed to be replaced. Recognizing the limitations of red rubber gaskets, the end-user decided to find something more durable, that could withstand a frequent cleaning cycle. Contacting the European tank manufacturers for a solution would be both costly and time-consuming and large companies in high demand can afford very little downtime, so a quick solution was needed. The maintenance manager decided to source a solution much closer to home and most importantly, comply with strict FDA standards.

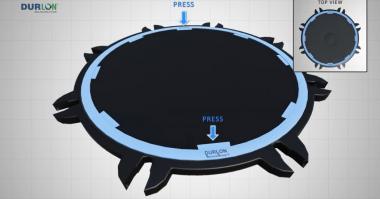

Durlon® 9000 PTFE gaskets replaced the red rubber as a more durable and high performing sealing solution. Durlon® 9000 is for use in process piping and equipment in the food & beverage and other general industrial applications. In addition, the shape of the fillers do not allow wicking which can cause corrosion on flange surfaces and conforms to FDA requirements.

The end-users were pleased with the level of support and service they received from the customer service and technical teams. Durlon® 9000 has proven itself to be a high-performance solution, allowing for frequent maintenance on the tanks in which they are used. In addition to solving the end-user issues, we were able to supply the company with Durlon® Joint Sealant to use as a temporary and cost-effective solution when periodically opening the tank doors for visual inspections and routine cleaning.

![Durlon Chemap® filters solve filtration tasks in a simpleand economic way [Case Study]](http://test.empoweringpumps.com/wp-content/uploads/2022/12/Durlon-Chemap®-filters-solve-filtration-tasks-in-a-simpleand-economic-way-Case-Study-7-380x199.png)

Comments