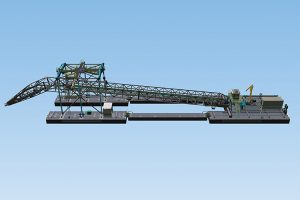

Six TB Wood’s Form-Flex disc couplings serve as the drive shaft of an underwater sand mining dredge designed to operate in a harsh environment with low maintenance for 40 years. The 120 ft. long drive train which connects a 600HP motor to a suction pump operating at the bottom of an underwater sand mine is the longest ever built for the mining dredge industry.

Engineers from TB Wood’s designed a custom hub with a unique flange disc pack and tapered bushing mounting to facilitate ease of installation and adjustment to the underwater pump impeller. The special long, taper lock mounted hubs allow easy field service and axial adjustment of the pump impeller necessary because, over time, it becomes worn down by the abrasive sand material.

Engineers from TB Wood’s designed a custom hub with a unique flange disc pack and tapered bushing mounting to facilitate ease of installation and adjustment to the underwater pump impeller. The special long, taper lock mounted hubs allow easy field service and axial adjustment of the pump impeller necessary because, over time, it becomes worn down by the abrasive sand material.

The Form-Flex couplings were also specially modified to run in the vertical position required in this dredging operation. The flexible tubular couplings solved a deflection problem for the customer while also reducing the weight of the ultralong drive train.

The couplings were selected because of their ability to handle parallel offset and angular misalignment which was critical for this huge mining dredge. TB Wood’s engineering support and custom-engineered solutions were significant for this long-time customer in designing the world’s largest mining dredge.

Comments