Introduction

As a startup that has been recognized for its innovation in food safety, Clean Works quickly recognized its unique position to help fight COVID-19 by using its produce disinfection technology to disinfect critically-needed masks and other personal protective equipment (PPE).

Clean Works was founded in Ontario, Canada, in 2012, by produce industry veterans who saw the need to improve the fruit and vegetable sanitation to prevent the outbreak of foodborne illnesses. Traditionally, post-harvest washing was used as a decontamination treatment. However, this highly water consumptive process only offered about a 50% contaminant reduction.

So, Clean Works designed a process that uses ultraviolet light, vaporized hydrogen peroxide and ozone to kill 99.99% of pathogens, providing a more effective and consistent cleaning process while reducing water consumption.

As the world faces the COVID-19 pandemic, the technology in the Clean Flow Mini can sanitize up to 1,200 N95 masks per hour. Through its newest affiliate, Clean Works Medical, the company is offering the Clean Flow Healthcare Mini to meet that need.

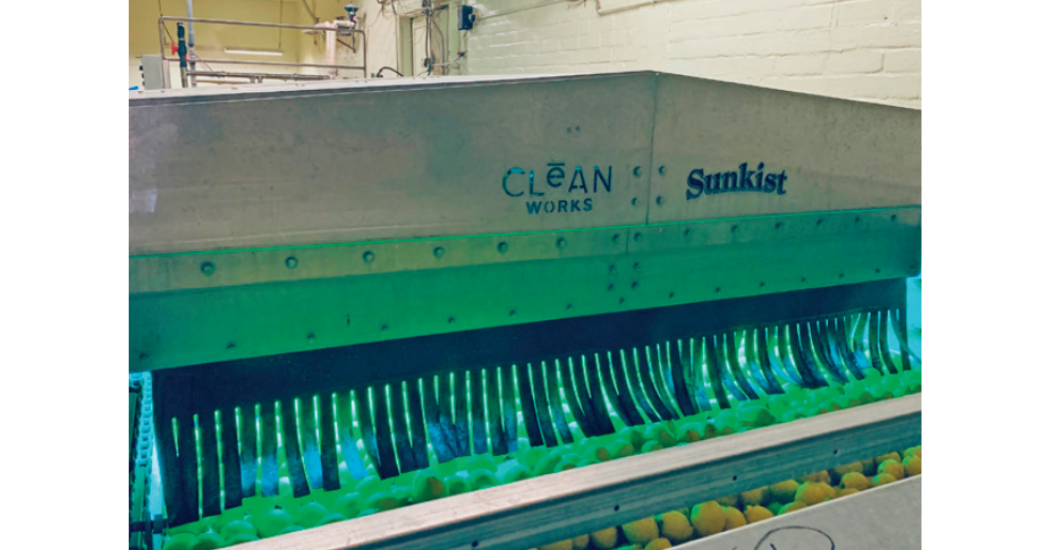

The food industry uses the Clean Works Clean Flow Mini to kill 99.9% of pathogens.

The Situation

A key component of the Clean Flow Heath Care Mini is a chemical metering pump that provides continuous dosing of Clean Works sanitation solution. Precise control of the dosing levels and constant spray are essential to effective sanitation, whether sanitizing produce or PPE.

Previously, Clean Works had used peristaltic dosing pumps in their Clean Flow Mini, but these pumps were unable to provide continuous atomization and required additional time for maintenance.

“Pulsation was a big issue with the previous pump manufacturer,” said Joe Symons, general manager of Clean Works. “We needed a fully integrated solution that could deliver the needed accuracy and precision while communicating with the PLC controls.”

The Grundfos DDA has been fully integrated into the Clean Works Clean Flow Mini for produce.

The Solution

Committed to ensuring the pumps worked with the innovative procedure, the Grundfos team began testing its DDA pumps with the Clean Works nozzle and chemicals.

“The atomizing was really cool to see,” said Aninda Sarker, Grundfos district sales manager. “As we tested the solution with our pump variants, I took a video for the Clean Works team, so they could see the pump in action. I also joined them at the plant for on-site testing.”

By using stepper motor technology, Grundfos SMART Digital dosing pumps provide a smooth continuous flow profile, even when very small volumes are required. Additionally, an integrated pressure sensor and flow monitoring algorithm controls the flow rate by comparing the actual flow to the set point and automatically making any needed adjustments.

The pump’s IP65 certification means it can safely be mounted outside the machine, conserving critical space inside the equipment.

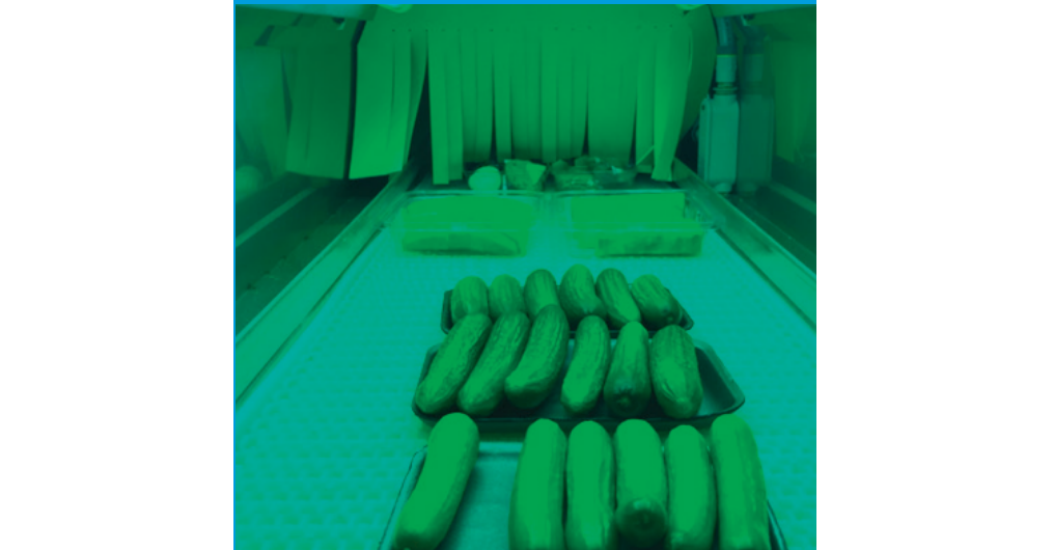

The Clean Works Clean Flow Mini sanitizes produce using ultraviolet light, vaporized hydrogen and ozone.

The Outcome

The Grundfos DDA has been fully integrated into the Clean Works Clean Flow Mini for produce, as well as the Clean Flow Health Care Mini.

“This pump has completely alleviated our maintenance worries, and it’s hands-free,” said Paul Moyers, co-owner of Clean Works.

Due to the shortage of N95 masks and other PPE, Clean Works’ newest affiliate, Clean Works Medical, has seen increased demand from healthcare providers and industries for the Clean Flow Healthcare Mini and the chemical dosing pumps that are critical to its functionality.

Grundfos worked with its global operations teams to quickly meet the increased demand for DDA dosing pumps for Clean Works to ensure the company’s innovative solution can be deployed to sanitize equipment that protects the frontline workers who are helping save lives.

Clean Works Medical is working with the federal and provincial governments, as well as hospitals, nursing homes and other healthcare facilities in Canada, to supply sanitized equipment during the pandemic.

“The key was to quickly provide a PPE solution to our frontline healthcare providers during this crisis, and Grundfos was an integral part of that,” said Mark VanderVeen, president and CEO of Clean Works.

Comments