High-quality pumps and valves are extremely important in the water and wastewater sectors – but they alone do not guarantee a perfectly working system. It is only by selecting the right system components and incorporating them in the pumping station that a flow-optimized system is created in which maximum output, a long service life, and optimum energy efficiency go hand in hand. KSB, therefore, offers support to consultants, plant engineers, and operators with a wide selection of engineering services that can address different stages of a project.

On request, KSB will assess all project-relevant factors and prepare installation designs and budget quotes long before construction work begins. We can oversee the project through all phases of system planning and construction, contributing expertise where it counts while always pursuing the goal of creating an optimized and efficient system for the operator.

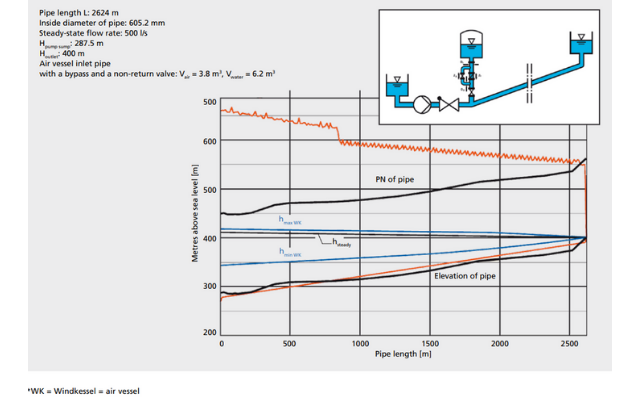

Result of a transient flow analysis: the “pressure envelopes” of dynamic pressure changes after pump failure with and without air vessels

Comprehensive services for all key areas

In every planning and execution phase, you can also use other KSB services to ensure the smooth functioning of your installation. As well as hydraulic calculations, we also assess economic feasibility and take care of system analysis and optimization. We provide project planning services and help you to select suitable pumps, auxiliary equipment, or alternative drives such as diesel motors. In addition, we advise you on achieving more energy-efficient systems and assist you with designing the optimum intake and outlet structures and optimizing your pumping station. If required, we also perform model tests and CFD simulations, conduct piping system analyses, transient flow analyses, flow simulations, and hydraulic calculations. KSB’s trained professionals are on hand to provide support with commissioning and test runs of KSB equipment. Furthermore, we assist with designing control concepts, handle installation management, take care of on-site servicing, and last but not least, provide training for your employees.

I need dealrship of KSB Submersibal Pump set.