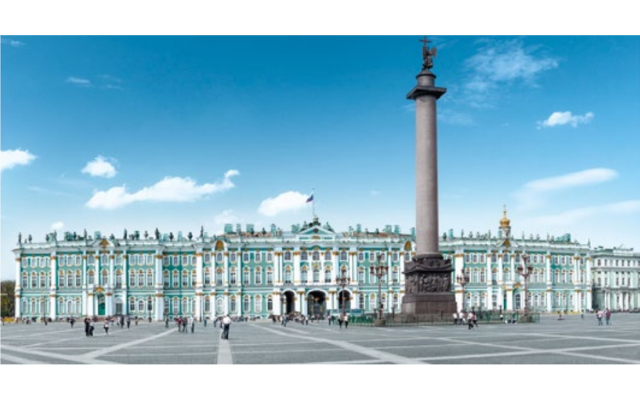

In St. Petersburg, Russia, a major waste water project has been under way since 2005. The aim is to conserve water resources and to protect the Baltic Sea against the discharge of untreated waste water and associated eutrophication.

One of the most important sub-projects is the deepest waste water pumping station in Europe, which reaches a depth of 92 metres. Here, numerous pumps from KSB handle the rainwater and waste water that collect from a twelve kilometre-long tunnel system. An average of approx. 600,000 m³ of waste water is pumped into a channel from which it flows by gravity to the waste water treatment plant.

The bulk of the work is carried out by 12 dry-installed pumps from the Amarex KRT K 400-710 submersible motor pump range. With a nominal power of 580 kW per hour each, they transport 2,592 m³ of waste water at a head of 59 m, achieving 81% efficiency. In addition to the main pumps and frequency inverters, KSB also supplied a number of drainage and sump drainage pumps.

Incorporating control equipment for each pump and an uninterruptible power supply (UPS) system complete with power cables, control cables and cable ducts, the control cabinets installed play a crucial role in ensuring the effective functioning of the entire system.

Complete supply programme for waste water transport

From municipalities and cities to industrial companies, individual buildings and private households, KSB provides comprehensive solutions for waste water transport. Whether performing surface drainage or transporting aggressive waste water, we offer a broad range of technically advanced equipment for waste water transport, pumping stations and sewage treatment plants. This is complemented by decades of experience and our bespoke all-in solutions.

KSB provides powerful waste water lifting units, pumps for pumped drainage and special solutions for residential areas with a high groundwater table or for buildings in water protection areas. But that’s not all. We also offer propulsive jet pumps for use in stormwater retention tanks or waste water pump stations with an integrated solids separation system.

KSB’s products are optimised for minimum energy consumption and a maximum life cycle. Our in-house materials laboratories develop wear-resistant materials that are extremely resilient to corrosive and abrasive waste water. From these materials our foundry staff produce highly durable components that can withstand adverse conditions for many decades, providing an important basis for minimising the costs of waste water transport in the long term.

Nice post! Thanks for the explanation.