Patrick Hogg uses home-grown skills and on-the-job experience to close the talent gap and make an impact providing customized system engineering solutions for NIDEC customers

While growing up on a farm in Southern Illinois, Patrick Hogg learned quickly how to channel his ‘inner MacGyver’ to creatively repair all kinds of motors and equipment even when specific parts and tools were unavailable. Finding a combination of intuitive mechanical know-how and inventive ingenuity was the name of the game.

“If something breaks on a farm, you have to find a way to fix it because your livelihood depends on it,” Hogg explains. “When you live on a farm, you develop an understanding of the mechanical side and how it should work, but you also have to get creative.” Two decades later, the 2016 Hydraulic Institute Young Engineer of the Year does the exact same thing every day for Nidec Motor Corporation’s Commercial and Industrial Motors and Drives Division as the former Director of Engineering turned current Director of Marketing.

His approach to problem-solving rather than simply selling products involves putting together a complete puzzle to create the most effective solution for his customers.

“Motors are everywhere!” Hogg declares. “In fact, my wife always teases me because I’m always pointing out the motors all around us all the time. But you have to understand more than just the motor. A lot of driven equipment, including pumps, have a motor; so you must understand how that equipment works as well. Then you need to know how the sensors that feed that equipment work. Then you must consider efficiency, waste, reliability, and how all this works together. It’s all interconnected. Having this mindset helps us to create full-bodied integrated solutions for our customers.”

Through system engineering, Nidec drives change by providing solutions rather than just selling products off the shelf. Integrating multiple products can reduce complexity while also improving energy efficiency, creating a smaller physical footprint, and reducing waste.

Finding these integrated customer solutions is the driving force for Nidec. Of course, there is a process.

How to Help End Users Find Integrated Solutions

Sometimes a solution is simple. Nidec engineers can take a high-quality piece of equipment out of its catalog of products and incorporate it easily into a customer’s application. In other instances, the solution requires ingenuity and creativity.

Hogg said that when he works with a new customer, he asks three general questions that help them find the best possible solution.

- What is the problem? “I think the key point is to find out what is the point of the problem.” Hogg clarifies. “What is not working for you? It’s important to have an understanding so that the engineers can wrap their brain around that problem and find the best solution.”

- What keeps you up at night? “It is essential to find out what are the customer’s pain points,” he said. “Sometimes initial cost is most important. Or perhaps it’s reliability and cost over time. When we know the pain points, we can work the solution around that. If I can find the answer to make them sleep better at night, then I’ve done my job well.”

- What are the specifications? “We have to ask what we’re trying to move, how much of it, and how quickly. Then I can get the inputs and determine the desired outputs. The more specifics I can get, the better I’ll be able to help you solve the problem. This is how we move into finding a system solution.”

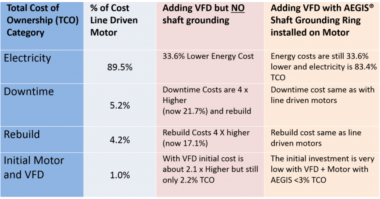

An example is integrating motors and drives. “What this allows us to do is create a single point of contact for the drive end of the equipment that also allows the motor to get some inputs,” Hogg said. “If we can attach a drive to the motor, then we can start putting inputs into that motor. This currently may require dealing with a Variable Frequency Drive (VFD) manufacturer and also with a motor manufacturer. Who do you call if you have a question or if something goes wrong? If we can provide a solution where there is ‘one-stop’ shopping for the integrated solution, it allows us to perhaps get rid of some confusion.”

The next step is providing accessories that may lower the cost of maintenance. “Again, we have to think about the pain points,” Hogg states. “If we can integrate the motor and the drive together and eliminate one of those pain points of having two different manufacturers as well as lowering the amount of accessories, then we have created an effective, integrated solution that will solve the customer’s problem.”

Engineering to Order

The larger equipment is more difficult to integrate because of its sheer size. For example, some 3000-horsepower motors used for industrial wastewater applications may be as big as an office. Nidec has a proven process that gets the customer what they need for these types of equipment. This process is called Engineered to Order (ETO). Nidec provides support to ensure the motor meets the required specifications. An engineered solution is then created for the end-user.

The process provides an engineering contact point to work on the specifications, while the marketing group focuses on what is needed in the market. “The big motors take more time and effort and are more challenging,” Hogg shares. “But Nidec specializes in this. We go through the project with a fine-tooth comb so there are no surprises on the other side. We want to ensure the best possible solution that Nidec can offer.”

While Nidec still offers an entire suite of high-performance stock products, the ETO program creates specific solutions that are specially customized.

‘We may have a standard model ready to ship when the customer needs it right away, but when we get that specific input and requirements on projects, we have the capability to customize it,” ruminates Hogg. “It’s all about giving the customer a solution rather than just a product. And we never forget to consider the pain points. If they need it quickly, for example, and that is their pain point, then perhaps something we have on the shelf will work with a few simple modifications, and we can get it to them in a hurry.”

Educating Young Engineers and Closing the Talent Gap

With an aging workforce, the talent and skills gap in manufacturing remains wide. Experienced engineers are retiring in masses and taking their decades of knowledge with them. This has created a need to train and inspire more young engineers, like Hogg (currently age 33), to pursue careers in engineering.

After years on the farm and a few years working with his brothers in construction, Hogg got his early engineering experience in a co-op role, similar to an internship with Nidec. “I was excited about the opportunity to find something where I could solve problems, but without all the hard labor,” Hogg said. “It’s not that I mind the physical labor, but I really enjoy solving problems with my mind. And this is something I can do when my body is eventually worn out.”

Hogg worked as an application engineer at Emerson Motor Company (*Emerson Motor Company is now Nidec) and spent some time with Whirlpool where he learned more about motors and pumps.

Hogg worked as an application engineer at Emerson Motor Company (*Emerson Motor Company is now Nidec) and spent some time with Whirlpool where he learned more about motors and pumps.

When he returned to Nidec as a large project administrator he began to see the breadth of products along with the expanded opportunities the pump and motor industry had to offer.

“Working with the ETO quotes, I began to see how Nidec’s motors could affect infrastructure and the world in general,” he said. “This inspired me to move toward this idea of creating a better tomorrow through today’s actions. Then I got involved with HI (Hydraulic Institute) and saw how these standards were really pushing the future of the industry.”

Through organizations like HI and NEMA (National Electrical Manufacturers Association) working together to find industry solutions, Hogg was able to find inspiration. He said this is the key to recruiting young engineers into the industrial segment.

Through organizations like HI and NEMA (National Electrical Manufacturers Association) working together to find industry solutions, Hogg was able to find inspiration. He said this is the key to recruiting young engineers into the industrial segment.

“We have to talk about how to make this a ‘sexy’ industry,” shares Hogg. “When you talk to these guys that are retiring, I always ask them how they got here. What inspired them? It helps to hear the stories about the projects they worked on and the problems they solved. You can really see the importance of the industry. If you can find what inspires these young guys, like maybe they want to work on SpaceX and go to Mars, or something like that, well, you can tell them that there are electric motors on a spaceship. We just need to change the perspective and help young engineers understand the importance of the products in systems that we are engineering.”

A Driving Force Educating the Masses

Nidec puts the concepts of educating and problem solving to good use with a popular blog called “Driving Force,” which combines innovation and learning to help inspire young engineers as well as continue to educate customers.

“We are dedicated to educating the masses on what electric motors can do,” Hogg explains. “Education affects innovation and moves the industry forward.” The blog covers energy efficient topics, variable speed applications, automated guided vehicle applications, and other motor-related topics that are important to the industry. It provides a lens to share innovative thinking, industry ideas, and shows how Nidec is helping with solutions for a better future.

Nidec also supports schools through coop programs that train young engineering students on new technologies.

Being a thought leader within the industry is important to Nidec and to Hogg. “Nidec supports the industry and pushes it forward through system engineering. We think our products have advantages over others, but what we really want to push home the fact that we strive to give the customer and the end-user solutions that solve problems. This is how we are going to make this whole world better-through innovation.”

About the Author:

About the Author:

Michelle Segrest, Reporting for Empowering Pumps.

Michelle is President of Navigate Content, Inc., a full-service content creation firm. She has reported about the industrial processing industries since 2008 and can be reached at michelle@navigatecontent.com.

Comments