Proper shaft alignment is a critical for proper operation of coupled pumps. But it is only one part. Preventive maintenance (PM) inspections are also essential to long-term operations. And PM must cover more than just lubricating bearings.

- Bolted fasteners, especially those that hold the pump and motor in place, should be checked.

- Seals should be checked for proper operation.

- Coupling elements should be inspected for wear, lubricated (if needed), and set screws and keys should also be checked.

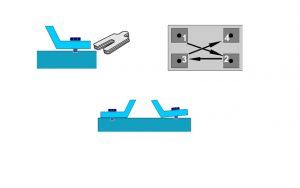

- The machine foundation, base plate, skid, and any other elements should be looked at. Lagging bolts should be checked for adequate torque. Look for broken welds, cracks, or other signs of degradation.

- Pipe hangers should be checked, and tensioned if needed. In many cases, pipe strain can be minimized or eliminated by proper use of piping supports. This should include the conduit used to connect the motor. Flex conduit, when overly bent, can also cause vibration problems similar to pipe strain, and can adversely affect shaft alignment.

- Check valves, strainers, and other piping accessories should be inspected for proper operation. Flexible piping connections should be checked as well.

- System pressure and temperature gauges should be checked for proper operation, and replaced as needed. While it may be “old school” in these days of computerized controls, pressure and temperature gauges can provide valuable insight into the pump’s operation.

- Shims under the motor should be checked, to make sure they are not loose or missing.

- Vibration measurements of the motor and pump can provide valuable insight into the machine’s health.

Viewing the motor and pump as a “system” consisting of more than just the motor pump is the best way to ensure long-term operational health.

Comments