In the wastewater industry, aeration processes are essential to achieving high water quality standards, but they can also be one of the largest energy consumers. This combination makes reliability and energy efficiency very important factors when operators are looking to replace existing blowers or install a new process.

Edward Paro, Portfolio Manager Compressors & Aeration at Sulzer, offers advice on specifying blowers and how to optimize performance while minimizing costs.

Blowers have been used in wastewater treatment plants for decades, which means that legacy equipment could be due for replacement or running costs need to be re-evaluated. Blower technology has also developed considerably over the years so reliability and efficiency have both improved. This means that cost savings made in the first few years of operation can quickly offset the investment in new equipment.

A suitable set of HST 20 blowers could be determined to meet the need and by appropriately adapting the pipework could be made to fit the existing blower room.

Gathering reliable data

Making the replacement of historic blowers a successful project relies on several factors. From the outset, understanding the requirements of the aeration application is essential but gathering the necessary information needs some thought. In the past equipment has been over-sized for many applications to build in future capacity, but this can confuse the picture when realistic figures are required.

Therefore, it best to avoid theoretical data, such as the air pressure and demand stated on the name plates of the existing blowers. Along with the total number of blowers, this information was based on the original application, which may have changed since the equipment was installed. Moreover, the performance of the blowers today may have degraded, so it is important to obtain data on the current situation.

Current process data should be measured wherever possible over an extended period, but as a minimum, there should be information from both peak and low flow periods. Depending on the industry and housing in the catchment area, there can be a significant change between seasons. These figures can be combined with datalogging information from the supervisory control and data acquisition (SCADA) system, which may allow records going back months or years to be used.

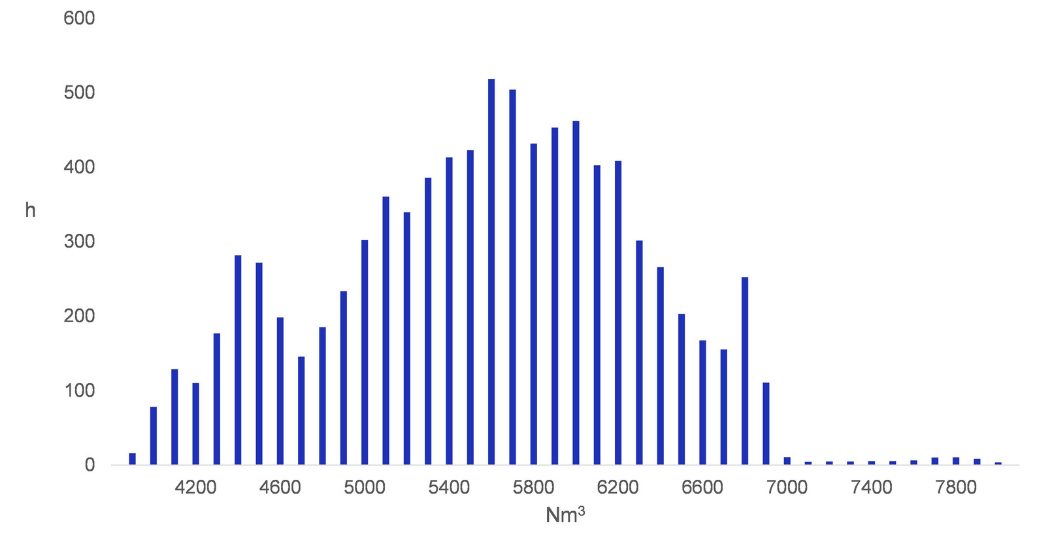

An example of data where air flows have two distinctive peaks.

Fresh figures

The historical information, however, needs to be calibrated to any sensors used to gather fresh data for the project. In this way, all the figures are comparable and can be used in the analysis phase. This can be compared with metrological information to reflect how rainfall and ambient temperatures affect the process.

The installation of any new sensors, especially flow measuring equipment, needs to be carefully considered. The most reliable data will be obtained in sections with laminar flow, which is found downstream of a straight section of pipe, ideally more than ten diameters from any obstruction or bend.

Equally, it is important to gauge the energy consumption of the aeration process because this will benchmark the efficiency of the blowers and establish an important component of the running costs. Combined with the expense of annual maintenance, this baseline figure will enable the return on investment to be calculated once the project is complete.

Data analysis

Once the data has been collated, it needs to be presented as a histogram to enable analysis. This will establish the distribution of flow and pressure data points, allowing mean and peak values to be established for different periods of the year. The final shape of the histogram will also provide further insights.

Plotting the data will usually produce a normal distribution establishing the most common flowrates as well as the minimum and maximum figures, which occur in equal measure away from the mean. The variance of the curve determines the percentage of values within one standard deviation of the mean. A distribution with a variance of one will see 95% of the values within two standard deviations from the mean.

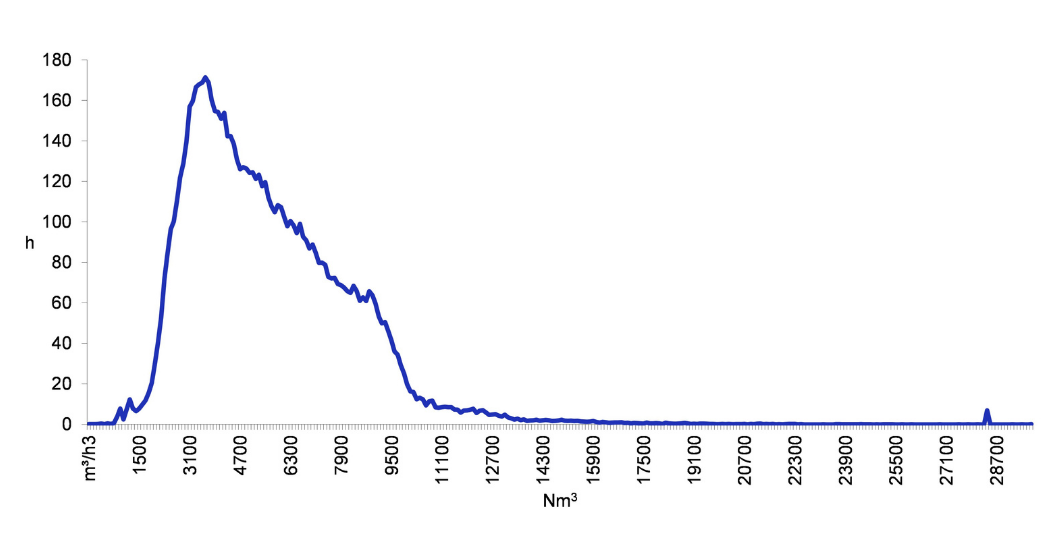

If the aeration process has seasonality, the data distribution can be represented by two peaks, one for off-season and one for high-season (see graph 1 for an example of this). If the graph is skewed to the left, this implies either some data is missing or the blowers are running at minimum flow but still exceeding process requirements (see graph 2 for an example). This can be caused by over-specification of the aeration equipment by the original designers.

If the graph is skewed to the right, the blowers are unable to deliver maximum demand. This can be caused by an increase in local population, resulting in a greater volume of wastewater compared to the original design specifications. In either case, further investigation would be necessary to understand the whole picture for these applications.

An example of data where air flows are skewed to the left.

Assessing proposals

The interpretation of this data is essential in creating the most appropriate arrangement of blowers and their size, assuming that the existing pipework will remain in place. Blower manufacturers can draw up proposals based on this information and these will include the power rating as well as noise levels of the equipment.

Due to the improvements in design, materials and performance, it is unlikely that a 75 kW blower will be replaced by one of the same power requirement. More often, it will be possible to reduce the energy demand, based on the same pressure and flow requirements.

Any new installation will consist of multiple blowers for a number of reasons. Most applications will have a flowrate variance that requires at least two or three blowers working in parallel. A fourth would act to assist when higher flowrates were required and the fifth would be a standby unit to enable maintenance to be completed without affecting the aeration process. The size and number of blowers is preferably left to the blower manufacturer to decide. This way, usually a more optimal solution can be arrived at and the different proposals can be evaluated based on their real overall efficiency.

Reducing costs

A project aimed at installing new blowers should also review the control methods used to regulate air flow and pressure. Legacy systems often maintain a head of pressure and use control valves to adjust the flowrate. The efficiency of this system can be improved through the introduction of variable head pressure operation or modern control valves, which offer greater accuracy.

Once a choice of proposals has been received from the blower manufacturers, it is important to compare them in terms of life cycle costs, which should be over 10-20 years. The most obvious calculation is energy consumption as this will be the largest cost. Based on the proposed blower arrangement and the expected demand curve established in the analysis phase, the annual running costs can be calculated. Add to these the projected maintenance costs and the total yearly expense is achieved.

Provided all the proposals meet any expected expansion in the future and the arrangement meets the design scope, the figures from the blower manufacturers should be compared on an equal basis. At this point, it will also be possible to establish the return on investment and any annual savings over the existing installation. Furthermore, the power and flow measuring equipment can be reinstalled after the project is complete to confirm the expected energy savings.

Long-term reliability

Throughout the process, it is important to consider various designs and technologies; modern engineering offers many benefits over legacy equipment. Reliability is a very important characteristic and coupled with energy efficiency, they can offer the optimum solution for aeration processes. Sulzer’s HST range of turbo blowers, for example, is designed for long-term performance with optimized costs.

In contrast to conventional blowers, Sulzer’s solution uses magnetic bearings, which offer running without mechanical friction or wear and provide excellent efficiency in terms of power usage and maintenance costs. Sales experts can support customers with detailed plans and the field service team provides experience and knowledge to deliver a turnkey solution. In every case, there is a strong argument to assess existing blowers and compare their performance to that of a modern system, which can often repay the investment in just a few years.

About Sulzer:

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class production facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2020, our 15’000 employees delivered revenues of CHF 3.3 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN).www.sulzer.com Our shares are traded on the SIX Swiss Exchange (SIX: SUN). www.sulzer.com. The Pumps Equipment division specializes in pumping solutions specifically engineered for the processes of our customers. We provide pumps, agitators, compressors, grinders and screens developed through intensive research and development in fluid dynamics and advanced materials. We are a market leader in pumping solutions for water, oil and gas, power, chemicals and most industrial segments.

Comments