When compared to VFDs, especially in medium voltage water and wastewater applications, Dynamatic® adjustable speed pump-drive systems can save you up to 65% in capital costs alone.

The operating efficiency of a Dynamatic adjustable speed drive increases relative to the normal operating speed of a motor, making them ideally suited for Pumps, Fans and Compressor applications. Rugged and reliable, Dynamatic® drives and digital controls are simple to maintain and have been proven to outlast VFDs by as much as 6:1. A Dynamatic® pump-drive system will dramatically reduce your lifetime operating costs.

Dynamatic® adjustable speed drives and digital controls are designed to be the smart choice for your business

When selecting an adjustable speed drive, it is necessary to select the drive that will perform the intended function at the lowest life cycle cost. The minimization of total cost coupled with careful attention to maintaining high operating speeds will result in the opportunity to generate increased profitability for the user. An Eddy Current drive with its inherent simplicity, ruggedness and performance features is your strongest candidate for lowest life cycle cost.

The acquisition cost of a drive system is generally the easiest to identify

Because Eddy Current drive systems are inherently simple and require fewer full power handling components, they have significantly lower acquisition costs. An Eddy Current drive has only two power conversion items, the motor and the clutch, to handle the full power. In general, the motor starter can be connected directly to the plant power distribution system appropriate for its HP rating.

Variable Frequency Drives with full power solid-state conversion units generally require a full-rated isolation transformer to minimize the effects of harmonic distortion on the power system. The controller for the Eddy Current drive is a low-power unit easily connected to any 115/230/460 single-phase power source.

Installation costs are minimized with an Eddy Current system

Because each drive type has different system components… foundations, wiring and cooling costs may also vary. DC and AFD controllers are generally packaged in large NEMA I convection or forced air-cooled enclosures which are susceptible to contamination. DC and AF controllers and transformers require additional floor space and installation labor. Often it is necessary to locate the conversion units remotely due to floor space limitations and at times in their own specially constructed “clean room”. Eddy Current controls, on the other hand, are small and can be located adjacent to the drive to minimize inter-connect wiring. When the environment dictates, they are easily packaged in totally enclosed NEMA 12 cabinets.

Operating costs center on energy, maintenance, repairs and downtime

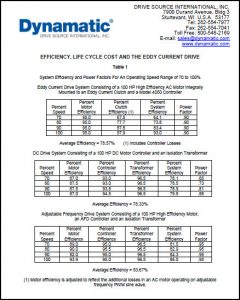

The cost of electric power is an important item to consider when evaluating the operating costs of various types of drives. The efficiency at each point in the operating profile must be considered for each drive type.

One of the primary objectives of any plant is to minimize downtime and maximize the availability of the machinery to perform its intended function. Downtime cost can easily run from several hundred to several thousands of dollars per hour. Considering the inherent simplicity and increased reliability of an Eddy Current drive, thousands or even tens of thousands of dollars can be realized annually from reduced downtime.

Maintenance and repair costs are major contributors to the cost of downtime. Simplicity is key to minimize costs in these areas. Dynamatic® drives can readily be serviced by plant maintenance personnel using basic troubleshooting techniques and equipment. Maintenance is simple bearing lubrication. The control, which typically consists of a single printed circuit board, requires no maintenance. Since one controller can operate drives from 1/4 to 200 HP, spare parts inventory costs are kept to an absolute minimum. The cost of replacement parts can be another area of concern. With the rapid changes in solid-state electronics controllers are obsolete approximately 4-5 years after introduction. Unfortunately, this is when these controllers are increasingly more susceptible to printed circuit board failures. Repair boards for vintage AF and DC systems can easily cost three times what they cost just a few years earlier and may be unavailable at any cost. This frequently leads to the user replacing the entire controller much sooner than anticipated, adding thousands of unexpected dollars to the life-cycle costs.

Since Eddy Current controls consists of a single printed circuit board, if replacement parts become unavailable, an entire control can be replaced for approximately five hundred dollars on drive systems up to 200 HP.

DOWNLOAD THE TECHNICAL PAPER: Efficiency, Life Cycle Cost, and the Eddy Current Drive. This technical paper discusses evaluation of life cycle costs, eddy current drive characteristics,

DOWNLOAD THE TECHNICAL PAPER: Efficiency, Life Cycle Cost, and the Eddy Current Drive. This technical paper discusses evaluation of life cycle costs, eddy current drive characteristics,

drive system acquisition, installation, and operating costs, annual savings comparisons, power factor, downtime, maintenance, and repair costs, and system efficiency.

Comments