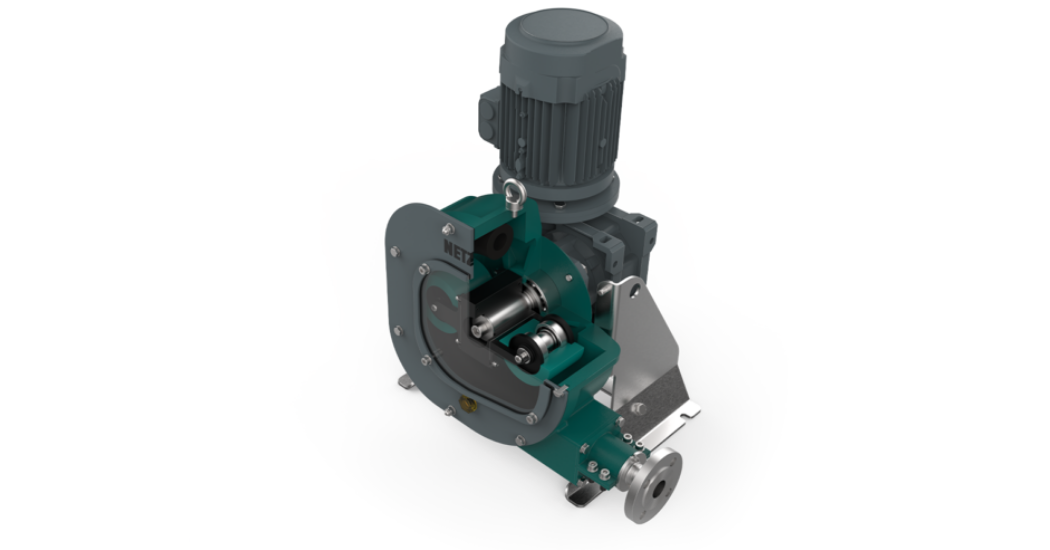

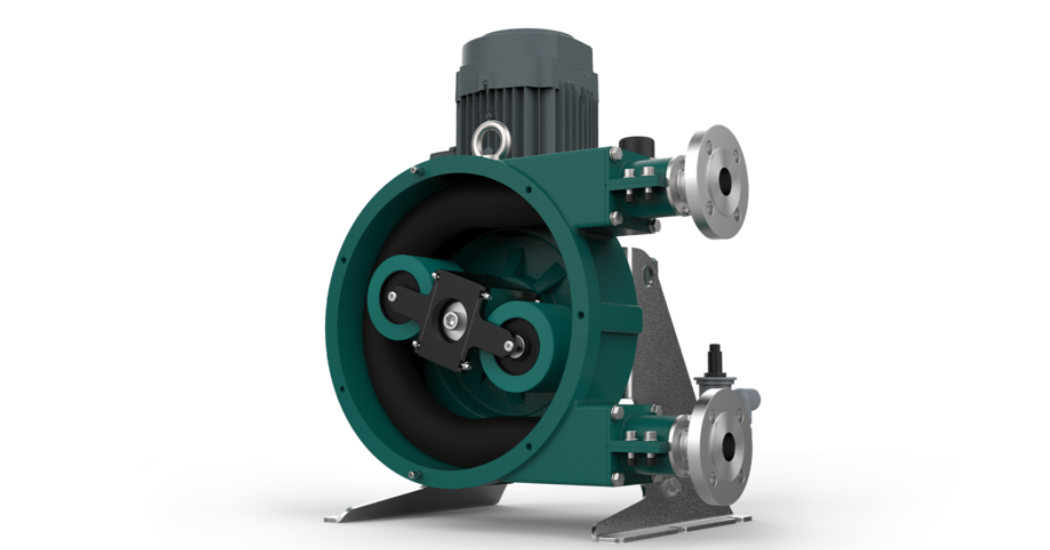

High savings in energy costs, versatility, and robust construction are just a few of the countless advantages PERIPRO peristaltic pumps from NETZSCH offer you in a wide variety of applications.

There are three different versions of the peristaltic pumps available. The portfolio consists of food, chemical, and industrial versions. We show you how you can benefit from the innovative high-performance pumps with XXL rollers.

1. Advantage: Low lubricant requirement of the PERIPRO peristaltic pumps

A significant advantage of the roller principle of the PERIPRO is that the load and thus the friction on the hose is significantly reduced compared to a pump with a sliding shoe. Thanks to the innovative design with the large rollers, you reduce your lubricant requirements by up to 90 percent. Thus you protect the environment and save costs at the same time. Especially with constantly rising oil prices, this is a factor that should not be ignored. At the same time, your service costs are reduced to a minimum.

2. Advantage: Versatile use – The PERIPRO peristaltic pumps

The robust PERIPRO peristaltic pumps are ideal for pumping abrasive, corrosive, viscous, or shear-sensitive media at up to ten bar pressures. This allows you to pump even the most demanding media such as milk of lime, sodium hypochlorite, adhesives, or sensitive polymers without any problems. The available materials of the hose are compatible with all types of products and working conditions.

3. Advantage: Lower energy costs due to PERIPRO peristaltic pump

In addition to residue-free cleanability, the peristaltic pump offers maximum efficiency and easy maintenance. With the innovative PERIPRO peristaltic pumps, you save up to 30 percent energy. This not only saves you money but also protects the environment. It is made possible thanks to the XXL rollers, which make a decisive contribution to reducing energy costs by increasing the service life. The large roller diameter minimizes the pump’s energy consumption while improving the service life of the hose.

The robust design of the industrial version enables you to convey abrasive and aggressive media in a wide variety of applications.

4. Advantage: Lower consumption of wearing parts with peristaltic pumps

A pump with only one wearing part? The PERIPRO peristaltic pumps make it possible. They have only one wearing position, the hose. This means that you, as the operator, only have to do a minimum of maintenance. The pump does not need any valves or mechanical seals, which reduces maintenance costs and the risk of leakage to a minimum. The hose is also exceptionally durable. This is made possible by a unique manufacturing process. It consists of an extruded inner layer, a high-density textile reinforcement, and a precision-manufactured outer layer, ensuring optimum compression. This minimizes your downtime and reduces maintenance costs at the same time. In addition, the XXL rollers protect the hose and increase the service life.

The PERIPRO in chemical design offers you the highest reliability even in conveying corrosive media with maximum dosing accuracy at the same time.

5. Advantage: PERIPRO enables easy hose replacement

Quick and easy assembly, commissioning, and maintenance are further advantages of the PERIPRO. The design of the peristaltic pumps from NETZSCH enables quick hose installation. Special attention was paid to high ease of maintenance during development. The innovative design makes installation and hose replacement easier for you. Without expensive special tools, you can remove the cover and remove the rollers and the hose. The food version is also CIP-capable (“Cleaning-In-Place”), i.e. the wetted parts can be cleaned without removing them from the system. The rollers can be easily removed via a flap in the lid.

The design of the peristaltic pumps from NETZSCH enables quick hose installation.

6. Advantage: PERIPRO peristaltic pump convinces with robust pump technology

Another advantage is the robust construction of the peristaltic pump. Durable materials, integrated bearings, XXL rollers and a reliable and secure connection system ensure maximum robustness. The innovative design of the pump also prevents the occurrence of leaks. The extra-large metal rollers and heavy-duty bearings allow you to pump the most demanding materials. This will enable you to pump slurries and media with a high solids content without any problems. Despite the robust construction, the peristaltic pumps are extremely compact. They are therefore ideally suited for use even in confined spaces. Nothing stands in the way of safe and environmentally friendly pumping and dosing of your products in a wide range of applications.

Comments