The Italian plant of one of the world’s largest food and beverage companies needed a reliable, efficient drive for a pizza packaging line. The shrink wrapping machine use drives to power the infeed conveyors. Traditional, stainless steel motors rated at 70-80 Hz had been used at the facility. To boost production the speed was increased to 80-90 Hz which created excessive heat causing the drives to fail.

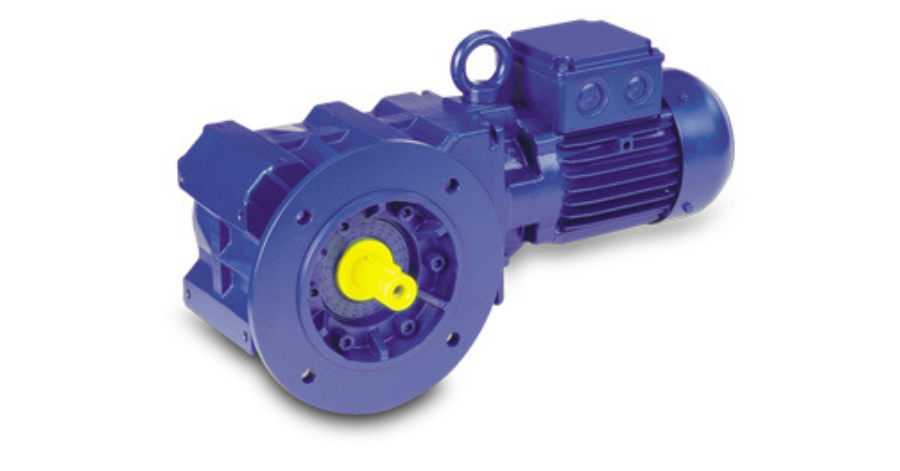

After a careful analysis of the conveyor application demands, Bauer engineers recommended a BK Series right angle bevel geared motor for improved efficiency compared to worm gear solutions. The Model BK06 supplied features a PMSM (permanent magnet synchronous motor) that reduces heat losses from the rotor by 100% and total losses by approximately 25%, while increasing total efficiency by 10% or more. This improved performance translates into a lower total cost of ownership, a reduction in CO2 emissions, and ongoing savings that buffer against future increases in energy costs.

Because PMSM motors provide efficiency at a wide range of speeds, it allowed the conveyor line speed to be adjusted up to 80 RPM when needed to meet production schedule targets.

Compact Bauer BK Series models are completely enclosed and sealed against dust and moisture. A hardened wear sleeve and spray ring ensure leak-free performance.

- BK Series helical bevel geared motors

- Hardened wear sleeve and spray ring ensure leak-free performance

- Complies with NA and International standards, including NEMA, IEC, CSA, and CE

- Low-noise gearing

- IP65 Enclosure (Standard), IP66 (Optional)

- Corrosion protection CORO1, CORO2, CORO3

- Connection Standard with CAGE CLAMP®

- Completely enclosed, sealed against dust and moisture

Comments