A major precision filling equipment manufacturer needed a reliable air motor/speed reducer for use on a new machine. During the pouch filling operation, a series of rotary valve pumps are used to control the flow of stir fry and other sauces. Over millions of cycles and in harsh washdown environments, this machine delivers precision-metered quantities.

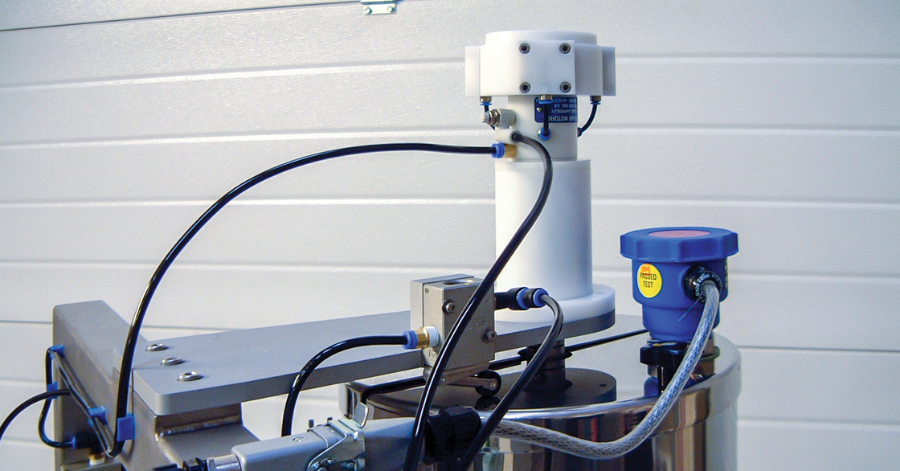

The combination air motor/speed reducer is mounted over the top of the sauce feeder hopper and drives a stirring shaft which extends into the hopper. A controlled shaft speed is required to ensure proper sauce consistency as it moves through the valve pumps and into the pouch packages.

To meet the OEM’s requirements, Huco Dynatork provided an Acetal Dynatork Planetary 1 combination air motor and speed reducer. The efficient piston air motor uses a reduced amount of compressed air which will provide savings to the end-user. Ideal for use in food processing and packaging applications, the Planetary 1 features Acetal construction to withstand washdown solvents and utilizes food-grade synthetic grease.

Highlights

•  Speed range: 0.62-162 rpm

Speed range: 0.62-162 rpm

• 354 in.lb. (40 Nm) Max. continuous torque

• Unique free-floating piston design provides precise control

• Uses 80% less air compared to vane motors

• Washdown-resistant housing

Read about more of Altra Industrial Motion’s motors in food and beverage applications.

Comments