If you read “Waterhammer Pressure Considerations” or know much about waterhammer, then you should know that it is a serious and complex issue. From a single transient event, a wide range of damaging conditions can arise. Now the question becomes focused on mitigation. While the instigating events may be unavoidable, an engineer can design means to account for the effects and meet code.

A common way to mitigate waterhammer is to manage the initiating event itself if possible. The simplest solution is to close the valve over a longer period. The previously mentioned Joukowsky equation predicts the pressure rise from an instantaneous change in flow. If that change is spread over time, then the resulting pressure wave is not as extreme. The longer the time interval for velocity change, the lower the magnitude of acceleration, and the lower the resulting force and pressure.

Like most of life, the reality is a bit more complicated. Each type of valve has unique characteristics. How you should close your valve depends on those characteristics. The suggestion mainly relies on how the Cv (flow coefficient) changes with valve position, and then how that valve position changes over time. If that Cv (thus, flow) changes dramatically near the end of valve closure, it is very important to close it slowly during that period.

There is a common valve closure practice known as the “80/20 rule”. That is, take 20% of the total time to close the first 80% of the valve, and then take the last 80% of the time to close the final 20% of the valve. Closing slower towards the end mitigates the surge because this is usually the moment of largest velocity change.

However, even this rule of thumb has its limitations. If the valve has a large pressure drop relative to the pressure drop of the entire system, then this valve may already have tight control of the flow. Changing the valve position affects the systems’ flow significantly. In this case the valve should be closed very slowly throughout the entire closure because every change in position is significant. Understanding your valves and their interaction with the system is important but difficult. This is yet another reason waterhammer analysis software is invaluable.

Surge Suppression Equipment

Of course, these mitigation efforts anticipate a planned closure. As shocking as it may be, unplanned transient events also occur. For instance, a power outage may cause a pump trip which then causes a check valve slam. In cases like these, in-line equipment are the means of mitigation.

Relief valves or rupture disks are common in-line components because they are a logical resolution to high pressure. Similar to a crumple zone in a car, relief components take the load on themselves. They pop open when pressures become too high, easing the effects on other parts of the process. Unfortunately, relief valves are sized for certain pressure scenarios, but those scenarios are not easily predictable. Thus, they are not an all-encompassing solution.

Vacuum breaker valves are another mitigation strategy with the opposite motive of relief valves. Those low-pressure situations we discussed earlier? The vacuum breaker valves are self-explanatory in how they help: they break the vacuum that can accompany a low-pressure condition, where the line pressure is below ambient pressure. They allow air into the system to relieve the low pressure.

That same breaker valve may also have a way for the air to escape when the pressure bounces back. With these multi-stage valves, the exit rate is very important to control. If the air leaves too quickly, the fluid columns may slam together, causing yet another surge event. While breaker valves are effective, they may not be practical if a process is sensitive to contamination or oxidation. An inherent limitation of single-stage breaker valves is the trapped air will cause a decreased area for liquid flow, and thus, will increase the fluid’s velocity. Additionally, the entrained air can negatively affect pumps and other components.

In addition to valves designed to relieve either high or low pressures, there are surge vessels that mitigate both extremes. Surge vessels come in many styles, but they are essentially in-line vessels that provide both a refuge and supply for process fluid during a transient. Two standard styles are open and closed vessels. Open vessels are also known as “standpipes” and are useful when contamination is of

little concern. Closed vessels are charged with an inert gas to control the compression and expansion.

When surge pressures arise, the vessels absorb the energy from the pressure spike, acting as an energy sink. When the low-pressure part of the wave cycle comes through, the vessels become an energy source, providing the necessary fluid and pressure. In that way they act like relief and vacuum breaker valves, but they are much more versatile. Closed vessels act for both the high and low pressures, while open vessels are typically designed for protection from low pressures. The nature of open vessels requires excessively tall walls if the vessel is to absorb a high-pressure surge; however, it is not unheard of.

Waterhammer Analysis Software

The ability to predict placement of mitigation components is no easy task. The design of the mitigation components themselves also requires the pressure predictions discussed earlier. Misplacing this equipment can make the situation even worse through resonance or re-triggering the surge. But most engineers work in plants that are, for lack of a better term, old. They inherit the system of the original designers, and that usually comes with relief valves or vessels scattered throughout. Without modeling software, this was a common way to protect against unpredictable surges.

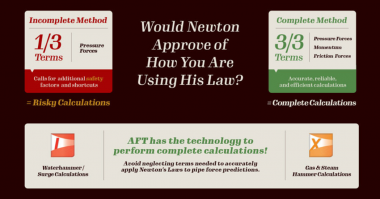

Without software to analyze wave behavior, process design becomes a rough estimate to meet code. These days modeling allows engineers to better predict events and the effectiveness of mitigation efforts. Targeted pressure control makes processes safer and more efficient. But more robust mitigation efforts require more robust technology for guidance. Being able to predict the unanticipated low pressures, column separation, and subsequent high-pressure waves requires more time and calculation than most engineers care to invest. After all, the system is probably designed for steady state.

Waterhammer software takes the pressure off the engineer by modeling the transient events, predicting expected behavior at various conditions, and checking the effectiveness of suppression methods. Even today, waterhammer analysis is not always part of the standard design process. Using the initially assumed “worst-case scenario” is often where the analysis starts and stops. Instead, take waterhammer analysis beyond the standard methods, and consider all the complex consequences of a change in flow.

Learn more at Waterhammer.com or if you’re interested in waterhammer software, visit: https://www.aft.com/

*Article originally published by Chemical Engineering Magazine.

Comments