Armstrong Fluid Technology is excited to be exhibiting at ISH 2019, the world’s leading trade fair focusing on the responsible management of water and energy in buildings, located at the Frankfurt Fair and Exhibition Centre. Located at stand A68 in hall 9.0 the Armstrong booth includes a range of the most innovative, high value solutions available in the industry. Armstrong’s fluid flow and control portfolio for commercial and domestic customers provide the highest energy efficiency and redundancy while offering solutions with the lowest installation cost, lowest operating cost and the lowest environmental impact.

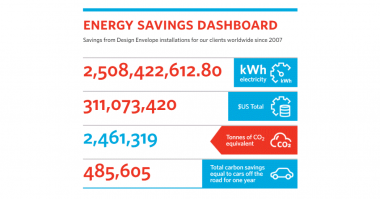

As part of the company’s commitment to global sustainability, Armstrong will also be highlighting its corporate initiative to reduce Greenhouse Gas (GHG) emissions 2 million tonnes by the year 2022. Achieving this goal would be equivalent to taking 600,000 cars off the road for one year, or offsetting the average annual CO2 emissions generated by 100,000 people.

“The ability to complement the Halm platform and legacy here in central Europe with Armstrong’s Canadian heritage of innovation and quality has been an ideal opportunity to further the education and access of our technologies in this market,” said Michael Schulz, Sales Director, Continental Europe, Armstrong said. “We’re excited to be leveraging this strong platform of product solutions to introduce more customers in Europe to our innovative technology and the Armstrong culture of service.”

One highlight of the display will be the Armstrong HEP Optimo range, a line of wet-rotor, variable speed circulator pumps for domestic applications. This product introduction is a result of the acquisition of the Halm Circulator brand by Armstrong, and allows Armstrong to serve customers across Europe with leading high efficiency technology in a cost-effective wet-rotor circulator line.

Demonstrating Armstrong’s commitment to innovation in Active Performance Technology is ‘Pump Manager,’ an Armstrong solution specific to Design Envelope pumps. Powered by the IBM Watson Cloud, Pump Manager serves as a platform to securely store and visualise pump data, execute advanced analytics, and deliver performance tracking notifications value to customers.

Another highlight of the stand is Armstrong’s internationally award-winning Design Envelope Tango, an intelligent, variable-speed pump. The Tango features Parallel Sensorless Pump Control (PSPC) a technology that improves the efficiency of a multi-pump installation through optimised load sharing. PSPC technology improves the efficiency of the full pump array by up to 30% over traditional multi-pump installations.

Also being showcased is the Armstrong Intelligent Fluid Management System (iFMS). These systems are designed and built off site to BS EN 1090 standards and to meet the specific requirements of individual projects. Serving both chilled water and hot water applications, the iFMS features Design Envelope technology that maximizes pumping efficiency by adjusting pump speed in response to system demand. The Design Envelope approach to sizing uses a combination of optimized impeller size and speed control to establish a range or envelope for most efficient operation.

For more information, please visit www.armstrongfluidtechnology.com.

About Armstrong Fluid Technology

With over 1,100 employees worldwide, operating seven manufacturing facilities worldwide, Armstrong Fluid Technology is known as an innovator in the design, engineering and manufacturing of intelligent fluid flow equipment. With expertise in demand-based control, digitalization, fluid flow, and heat transfer, Armstrong Fluid Technology leads the fluid systems industry, including HVAC, plumbing, and fire safety, providing the most energy-efficient and cost-effective solutions to building professionals and owners around the world.

Armstrong Fluid Technology is committed to sustainability. To underscore that commitment, Armstrong launched its 2 by 22 initiative, a program that aims to reduce Greenhouse Gas (GHG) emissions among customers by 2 million tonnes by the year 2022.

Comments