Armstrong Fluid Technology has introduced a new size range of Design Envelope Permanent Magnet pumps that are engineered to deliver 20% lower operating costs than variable speed pumps with standard induction motors.

The new pumps are available with motors ranging from15 hp to 50 hp, and operate at NEMA Ultra-Premium Efficiency levels that exceed the efficiency targets of both the US Department of Energy and the European Union.

“Better performance at higher RPMs means that in some cases a smaller Design Envelope Permanent Magnet Pump can deliver the same flow and pressure as a larger, more expensive competing model,” said David Lee, Offering Manager, Armstrong Fluid Technology. “These new pumps also feature smaller dimensions and are less expensive to purchase and install because permanent magnet motors offer a substantial reduction in both size and weight.”

Beyond the motor efficiency, a number of additional design innovations make the new Design Envelope pumps more energy-efficient and cost-effective:

- Armstrong’s patented Parallel Sensorless Control stages multiple pumps and regulates output for best efficiency across the entire pump array, saving 10-30% in operating costs

- Adjustable design points and setpoint based on the actual on-site conditions

- A quadratic pressure control curve that provides more efficiency than a linear pressure control curve

- A constant-flow function for maintaining a desired flow rate in recirculation applications

- Advanced connectivity via Armstrong’s Pump Manager, a cloud-based performance tracking service, provides industry-leading analytics and insights along with alerts, alarms and data storage

For additional information visit www.armstrongfluidtechnology.com

About Armstrong Fluid Technology

With eight manufacturing facilities on four continents, and employees around the world, Armstrong Fluid Technology is known as an innovator in the design, engineering and manufacturing of intelligent fluid flow equipment, control solutions and digital technologies.

In the shift toward digitalization and integration of fluid-flow systems, Armstrong leads the industry, bringing edge computing to mechanical systems, approaching energy optimization as a whole-building challenge and advancing the practice of full lifecycle management of mechanical systems. Focusing on HVAC, Plumbing, Gas Transmission and Fire safety applications, we provide energy-efficient and cost-effective solutions to building and facility professionals around

the world.

Armstrong Fluid Technology is committed to sustainability. In 2019, Armstrong signed the Net Zero Carbon Buildings Commitment, a program launched by the World Green Building Council. As a signatory to the program, Armstrong has pledged to ensure that all its offices and manufacturing facilities operate at net-zero carbon by the year 2030.

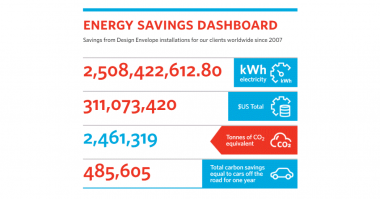

In 2018, the company announced a bold initiative to reduce greenhouse gas (GHG) emissions among its global customer base by 2 million tons, targeting completion by the year 2022. Armstrong recently reached and surpassed that goal, helping customers save 2.5 billion kWh of electricity usage, resulting in more than $300 million in cost savings.

Comments