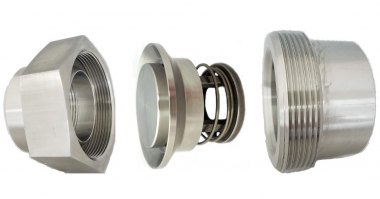

Check valves are a type of valve that allows liquids, gases, and steam to flow in only one direction. A check valve can have a ‘stopping’ mechanism that can be shaped like a ball, disc, piston, or poppet. Since all the valves we manufacture are inline spring-loaded piston/poppet style check valves, we are going to focus on these types of check valves by addressing a common question. What is a check valve used for?

To Protect Equipment from Backflow Damage

Spring-loaded check valves, which can be mounted in any flow orientation (with the right spring selection), prevent reverse flow. This particular check valve design incorporates a spring to assist in closing the check valve and does not require gravity or backflow pressure to function. When pressure changes in the piping cause flow reversal, check valves protect pumps and other equipment from damage caused by backflow. They are used in a wide variety of applications for flow control including, line isolation, priming pumps, media injection, maintaining head pressure, and many others.

Low-Pressure Relief Valves

Inline spring-loaded check valves can be used for low-pressure relief applications. Utilizing either elastomeric, thermoplastic, or metal to metal seals, these check valves can be custom-built with spring materials ranging from stainless steels to Titanium, Inconel, or many others. Different spring materials will perform differently depending on their unique properties. The key to pressure relief, in this case, is that the poppet moves away from the valve seat when the force of the upstream pressure exerts a greater force than that of the spring, allowing the media to pass through the outlet port. When sizing check valves for pressure relief applications, it’s important to know the set pressure and the maximum pressure the system can handle.

Dual Roles as Vacuum Breakers

In general, these check valves can be used as vacuum breakers. The purpose of a vacuum breaker is to allow air into the piping system for the purpose of preventing the interruption of the desired flow of liquid. A tank is a common application where a check valve would be installed at the top of the piping to relieve the vacuum when the tank is being pumped down. Another application where check valves can function as vacuum breakers is when there is a dramatic change in piping elevation. Vacuum relief valves can also be installed in vacuum systems in order to pull a specific amount of vacuum. Moreover, there could be some thermal applications where the media can change from very hot temperatures to very cold temperatures, and the differences in volume between temperatures is an instance that may require a vacuum breaker to relieve that vacuum when it is created as a result of a variance in temperature.

Engineering check valves since 1958, Check-All® Mfg. Co. is an outstanding source for all your check valve, vacuum breaker, and low-pressure relief applications. Use the comments to post your questions or tag us on social media. Stay tuned for our next article!

Comments