With global reputation for fire testing, our Durlon fire safe products are certified to various API standards by Yarmouth Research and Technology – an independent laboratory for the manufacturers and end-users of chemical process equipment, such as valves, packing, gaskets, seals and other flow control products. All testing is certified by a Professional Engineer. Third party test data from Yarmouth Research provides your customer the reliable information they need.

Fire Safe Tested Durlon® Products

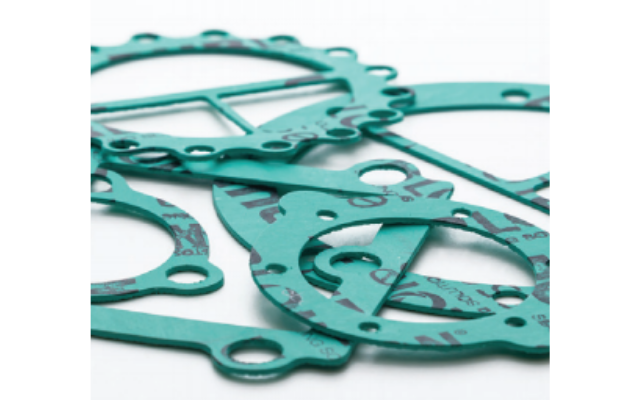

Durlon® 8500 is a high performance compressed gasket material for use in process industries including pulp & paper, food & beverage, pharmaceutical, hydrocarbon, chemical, refinery and general industry. Durlon® 8500 is suitable for oils, water, steam, new generation refrigerants, dilute acids and alkalis and many other liquids and gases.

Durlon® 8500 is a high performance compressed gasket material for use in process industries including pulp & paper, food & beverage, pharmaceutical, hydrocarbon, chemical, refinery and general industry. Durlon® 8500 is suitable for oils, water, steam, new generation refrigerants, dilute acids and alkalis and many other liquids and gases.

Fire Test Certification: (6” Class 300) API 6FB. The gasket tested is in compliance with the tightness criteria of 1ml/(inch • min) of API 6FB during burn period and cool-down.

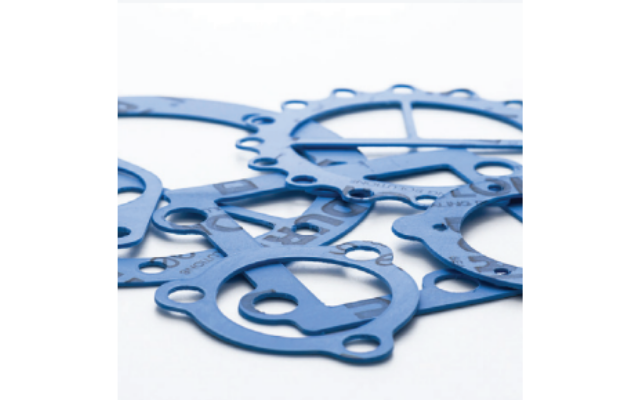

Durlon® 8900 is a premium grade material for service conditions to 496°C (925°F) and continuous operating temperatures of -73°C to 400°C (-100°F to 752°F). Suitable for saturated and superheated steam, oil, dilute acids and alkalis, hydrocarbons, and solvents.

Durlon® 8900 is a premium grade material for service conditions to 496°C (925°F) and continuous operating temperatures of -73°C to 400°C (-100°F to 752°F). Suitable for saturated and superheated steam, oil, dilute acids and alkalis, hydrocarbons, and solvents.

Fire Test Certification: (6” Class 300) ANSI/API Standard 607, Sixth Edition. The measured leakage was 0 ml/min with the max allowable external leak rate of 150 ml/min.

Durlon® 9000 is for use in process piping and equipment in chemical, pulp & paper, food & beverage and other general industrial applications where resistance to highly aggressive chemicals is required. In addition, the shape of the fillers do not allow wicking which can cause corrosion on flange surfaces and conforms to FDA requirements.

Durlon® 9000 is for use in process piping and equipment in chemical, pulp & paper, food & beverage and other general industrial applications where resistance to highly aggressive chemicals is required. In addition, the shape of the fillers do not allow wicking which can cause corrosion on flange surfaces and conforms to FDA requirements.

Fire Test Certification: (6” Class 300) API Standard 6FA, Third Edition. The test fixture was subjected to an external flame of 875°C (1607°F) average for 30 minutes. The measured leakage was 1.8 ml/min, where the max allowable limit is 1200ml/sec.

Durlon® HT1000® consists of phlogopite mica paper impregnated with an inorganic binder at less than half the binder amount found in vermiculite-phyllosilicate filled products. This lower binder content allows for superior weight retention, less than 4% weight loss at 800°C (1,472°F), and results in ultimate extreme temperature sealing performance up to 1,000°C (1,800°F).

Durlon® HT1000® consists of phlogopite mica paper impregnated with an inorganic binder at less than half the binder amount found in vermiculite-phyllosilicate filled products. This lower binder content allows for superior weight retention, less than 4% weight loss at 800°C (1,472°F), and results in ultimate extreme temperature sealing performance up to 1,000°C (1,800°F).

Fire Test Certification: API 607, 4th edition with Exxon modifications. The measured leakage was 7.3 ml/min with the max allowable external leak rate of 300 ml/min.

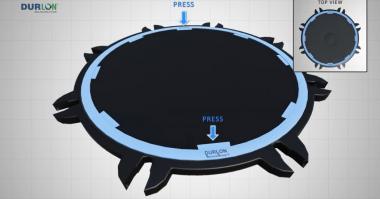

Durlon® Durtec® with Durcore® gaskets are made with a specially engineered corrugated metal core that is bonded on both sides with soft covering layers, typically flexible graphite. The core is produced by patented technology that allows the finished gasket to have the best possible mechanical support function. Corrugations in the Durtec® core are virtually un-crushable unlike conventional corrugated metal core gaskets.

Durlon® Durtec® with Durcore® gaskets are made with a specially engineered corrugated metal core that is bonded on both sides with soft covering layers, typically flexible graphite. The core is produced by patented technology that allows the finished gasket to have the best possible mechanical support function. Corrugations in the Durtec® core are virtually un-crushable unlike conventional corrugated metal core gaskets.

Fire Test Certification: (6” Class 300) Passed modified API 607 fire test and meets the requirements of Shell Specificaion MESC SPE 85/203 & PVRC SCR Flexible Graphite Spec for FG 600 material.

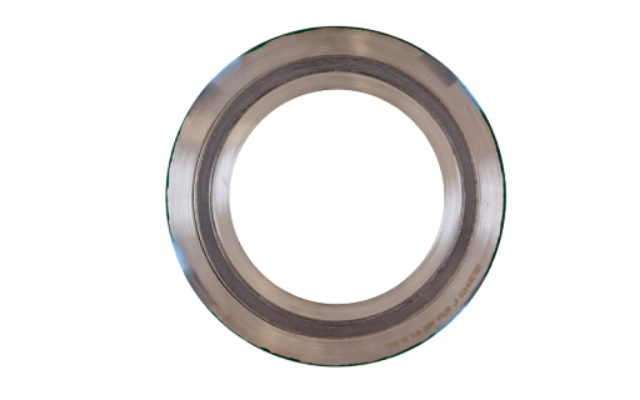

Durlon® Spiral Wound (SWG DRI ETG) Gaskets are made with an alternating combination of a preformed engineered metal strip and a more compressible filler material which creates an excellent seal when compressed. The engineered shape of the metal strip acts as a spring under load, resulting in a very resilient seal under varying conditions.

Durlon® Spiral Wound (SWG DRI ETG) Gaskets are made with an alternating combination of a preformed engineered metal strip and a more compressible filler material which creates an excellent seal when compressed. The engineered shape of the metal strip acts as a spring under load, resulting in a very resilient seal under varying conditions.

Fire Test Certification: (6” Class 300) API 607, 4th edition with Exxon modifications Fire Test.

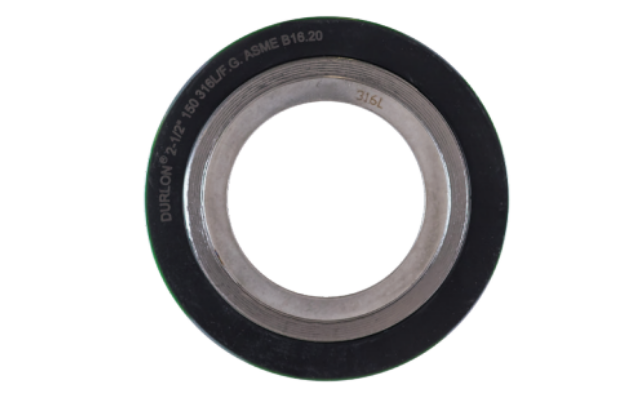

Durlon® Spiral Wound (SWG DRI FG) Gaskets are made with an alternating combination of a preformed engineered metal strip and a more compressible filler material which creates an excellent seal when compressed. The engineered shape of the metal strip acts as a spring under load, resulting in a very resilient seal under varying conditions.

Durlon® Spiral Wound (SWG DRI FG) Gaskets are made with an alternating combination of a preformed engineered metal strip and a more compressible filler material which creates an excellent seal when compressed. The engineered shape of the metal strip acts as a spring under load, resulting in a very resilient seal under varying conditions.

Fire Test Certification: (6” Class 300) FG SWG has passed the API Standard 6FB, Fourth Edition, 2019 Fire Test.

Durlon® CFG is a corrugated, flexible graphite gasket material designed for severe service conditions. The proprietary design of the corrugations gives CFG superior sealing and recovery characteristics for tough conditions in the refining, chemical, petrochemical and pulp and paper industries. Durlon® CFG is suitable for service in steam, oil, water, mild alkalis, mild acids, hydrocarbons and solvents.

Durlon® CFG is a corrugated, flexible graphite gasket material designed for severe service conditions. The proprietary design of the corrugations gives CFG superior sealing and recovery characteristics for tough conditions in the refining, chemical, petrochemical and pulp and paper industries. Durlon® CFG is suitable for service in steam, oil, water, mild alkalis, mild acids, hydrocarbons and solvents.

Fire Test Certification: Passed the modified API 607 fire test and are suitable in operaing maximum temperatures of up to 850°F (450°C) in air or 1200°F (650°C) in steam.

![Durlon Chemap® filters solve filtration tasks in a simpleand economic way [Case Study]](https://test.empoweringpumps.com/wp-content/uploads/2022/12/Durlon-Chemap®-filters-solve-filtration-tasks-in-a-simpleand-economic-way-Case-Study-7-380x199.png)

Comments