Considered an essential component, a flange is a type of mechanical seal that can connect valves, steam traps, strainers, and alike, in a piping system. While non-metallic flanges such as glass and reinforced plastic are used for some services, most flanges are metal.

Ultimately, and in their simplest form, two flanges are joined together and have a gasket placed between them. The importance in choosing the right gasket is vital to an application’s reliability and integrity. A critical and fundamental aspect of sealing is the level of friction between the flange and gasket surfaces. The roughness of the flange faces can have a dramatic effect on gasket creep relaxation, blow out resistance and bolted joint tightness. Depending on the type of gasket used in the connection, different flange surface finishes should be utilized to optimize gasket performance.

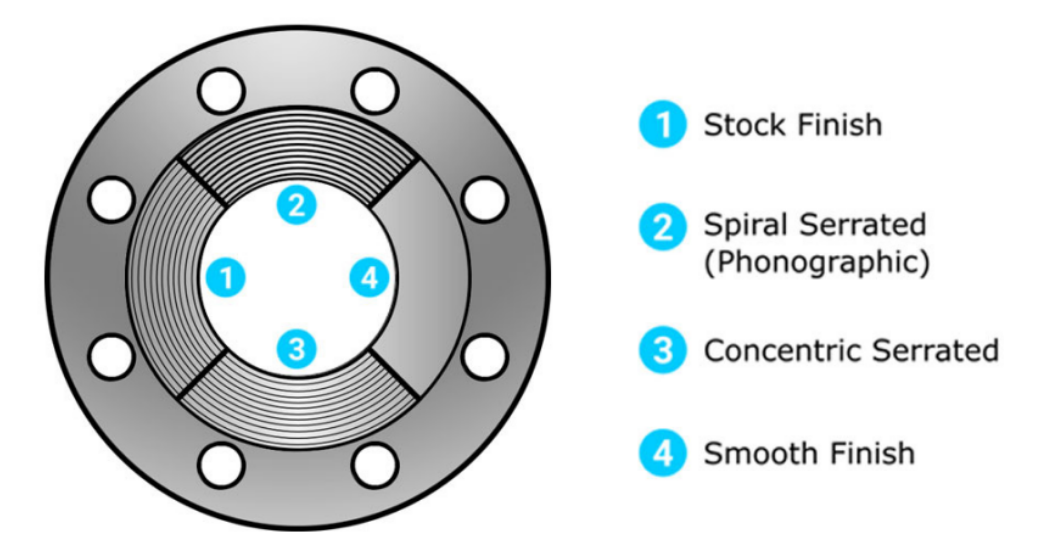

The 4 basic finishes for ASME B16.5 and B16.47 flanges are the Stock Finish, Spiral Serrated Finish, Concentric Serrated Finish, and Smooth Finish.

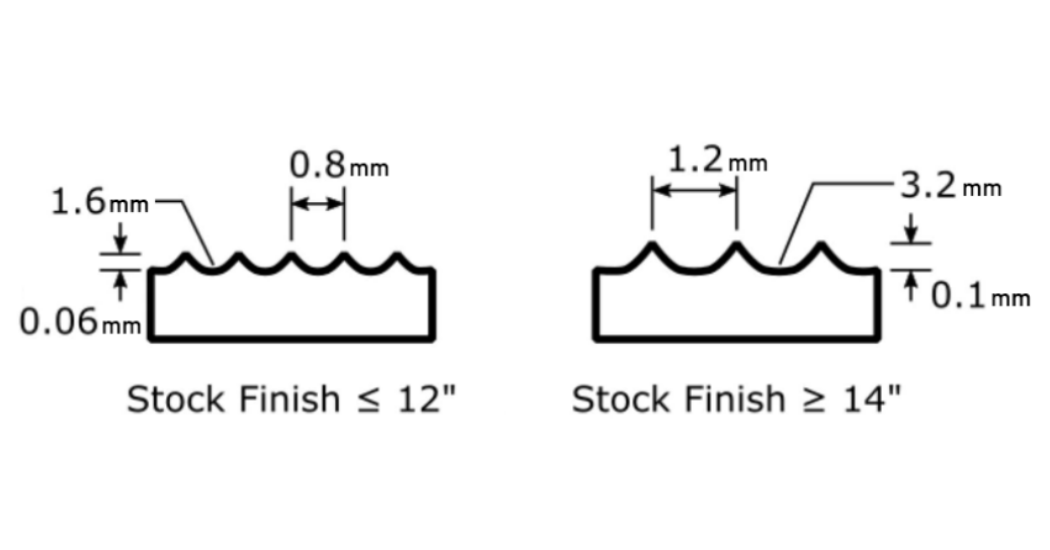

- Stock Finish

This is the Standard Flange Finish and most widely used, unless otherwise specified by the purchaser. The Stock Flange Finish is a continuous groove produced by using a 1/16” radius round nosed tool with a feed of 1/32” per revolution.

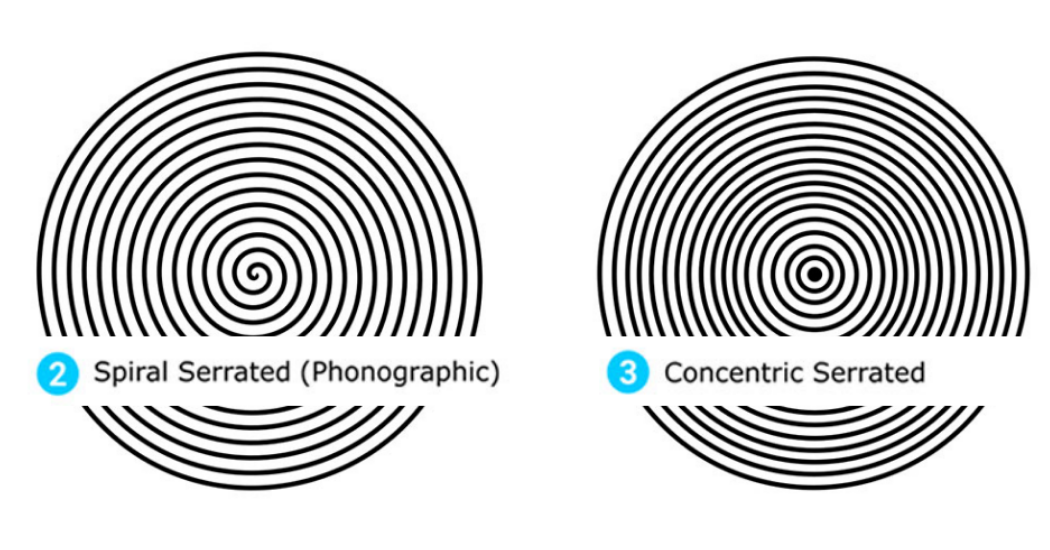

- Spiral Serrated Finish

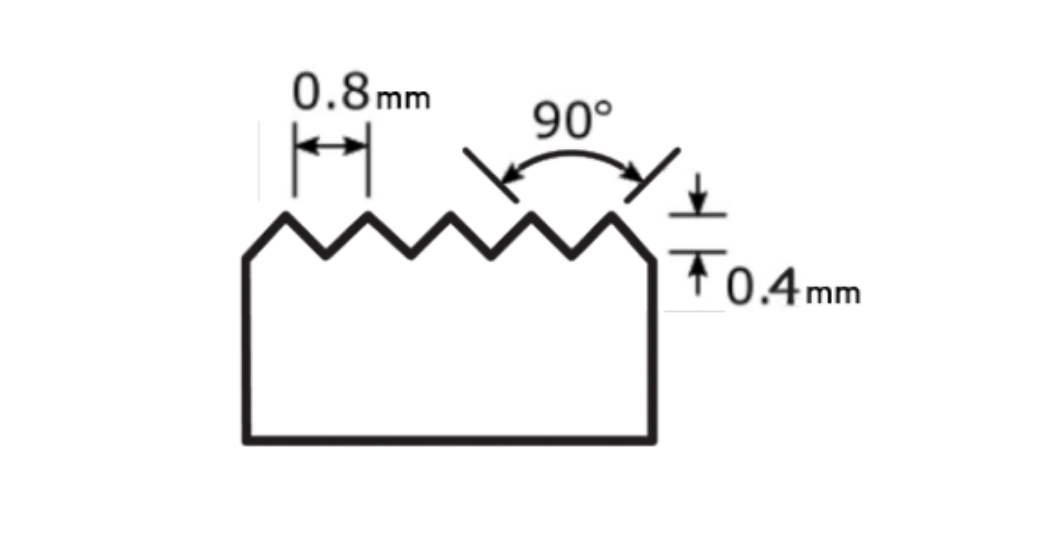

The Spiral Serrated Finish is also a continuous groove like the standard stock finish in that the groove is generated with a 90° included angle “V” tool. The Groove is 1/64” deep and the feed is 1/32” for all sizes. - Concentric Serrated Finish

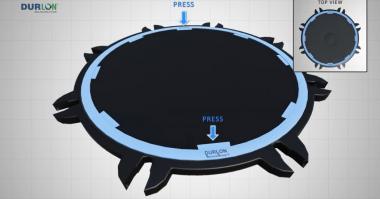

As the name suggests this surface finish is made up of concentric grooves. A 90° included angle “V” tool is used and the grooves are 1/64” deep and 1/32” apart.

Soft gaskets, such as compressed non-asbestos, PTFE gasket and flexible graphite composite gasket are most used to seal flanges with a serrated finish.  Smooth Finish

Smooth Finish

The Smooth Finish can be produced using several different shaped tools. This finish shows no visible serrations and has a 63-125 Ra. This finish in the past was commonly known as “Smooth Plane.” This term, however, should be avoided as it can be confused with “flat faced” which applies to the flange facing and not to the gasket surface finish. Smooth finish flanges are more common for low pressure or large diameter pipelines using Spiral Wound Gaskets.

Guidelines for a safe seal:

- A minimum seating pressure must be achieved to make the gasket material flow into the flange surface irregularities. The total force required to make this occur is proportional to the contact area of the gasket and the flange. Bolting force may be lowered by reducing the gasket area or the flange contact area.

- The closer together are the ridge surfaces of a concentric serrated finish and the shallower are the grooves (the Ra), the more the flange area begins to resemble a smooth face flange, and hence there is more contact area. Higher bolt loading is therefore required to seat the gasket. The opposite effect occurs as the ridge spans become wider.

- In the limit, with a very smooth flange there will be reduced friction restraining the gasket from extruding outwards under the influence of the internal pressure of the retained medium.

- A spiral serrated (phonographic) finish is more difficult to seal than a concentric serrated finish. Complete flow of gasket material must reach to the bottom of the ‘valley” surface in a phonographic finish to avoid a spiral leak path from one end of the spiral to the outside.

- Serrated and phonographic finishes are often associated with pipe flange assemblies, whereas commercial ground finishes are likely to be found in flanged joints other than pipe flange assemblies.

Summary

Summary

The finish or the condition of the gasket seating surface has a definite effect on the ability of the gasket to create a seal. Sheet gasketing is designed to have a seating stress that allows the gasket material to “flow” into the serrations and

irregularities of the flange face. This “bite” aids the gasket in resisting the effects of internal pressure, creep, and cold flow.

Flange surface finish is critical to achieve the designsealing potential of the gasket. Metallic, semi-metallic and nonmetallic gasket materials interact with flange surfaces differently. Each of these gasket types require specific ranges of surface finish for optimum gasket performance with lowest leakage. Metallic gaskets require a smoother flange finish than either semi-metallic or nonmetallic.

Again, gasket-leak tightness is dependent upon its operating gasket stress. Flanges that are warped, pitted, rotated, and have incorrect flange gasket-surface finish will impair the leak tightness of the gasket.

Follow ASME PCC-1 guidelines on contact surface finish, surface flatness, and defect depth to exploit the best gasket performance and avoid leaks. It is always best to consult with the gasket manufacturer to determine the best combination of flange surface finish, gasket design and gasket material(s)

Learn more about flange gaskets.

![Durlon Chemap® filters solve filtration tasks in a simpleand economic way [Case Study]](https://test.empoweringpumps.com/wp-content/uploads/2022/12/Durlon-Chemap®-filters-solve-filtration-tasks-in-a-simpleand-economic-way-Case-Study-7-380x199.png)

Comments