End-User Description

A Chilean open-pit mine that produces 75,000 tonnes of copper per year. It is part of a large natural resource company producing over 90 commodities worldwide and remains committed to the health and safety of its’ employees as well as environmental protection.

The Challenge

With commodity production, process engineers typically seek low cost/highly productive solutions. In this case, the end user uses heap leaching to separate copper from other biproducts. While heap leaching is an effective solution, mineral recovery is only about 60-70%, and highly aggressive chemicals are used and produced which can cause incompatible gasket material to break down and fail. Joint leaks in this scenario can pose a massive safety risk to workers, environmental concerns, and possibly a loss of revenue in the event of liabilities, time loss and lost product. Finding suitable materials for service in sensitive environments such as these, can be both time consuming and costly.

The Solution

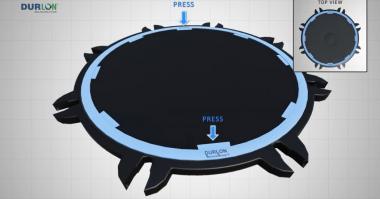

We began working closely with the mine engineers at providing a cost effective and high-performance sealing solution to help conduct refine from the leaching process. Durlon® 9000 was spec’d for its ability to withstand the leaching conditions and the material is compatible with both sulphuric acid and the refine.

The Benefits

The end-user discovered Durlon® PTFE through published data proving the material’s high sealability and were pleased to find that replacing their old ring gaskets with Durlon® products reduced previous joint leakage, helping to avoid fluid contamination and recover more mineral.

Check out the Durlon® 9000

![Durlon Chemap® filters solve filtration tasks in a simpleand economic way [Case Study]](https://test.empoweringpumps.com/wp-content/uploads/2022/12/Durlon-Chemap®-filters-solve-filtration-tasks-in-a-simpleand-economic-way-Case-Study-7-380x199.png)

Comments