We have had many conversations over the years with end users and installers, and the majority of the time, we realize that it wasn’t the gaskets fault for blowing. I often chuckle to myself wondering how the conversation would go if a gasket could talk to its end user? I think it would be very similar to the stereotypical relationship break-up line, “It’s me…it’s not you” but just the opposite, “It’s not me…it’s you” – gasket talking to the end user.

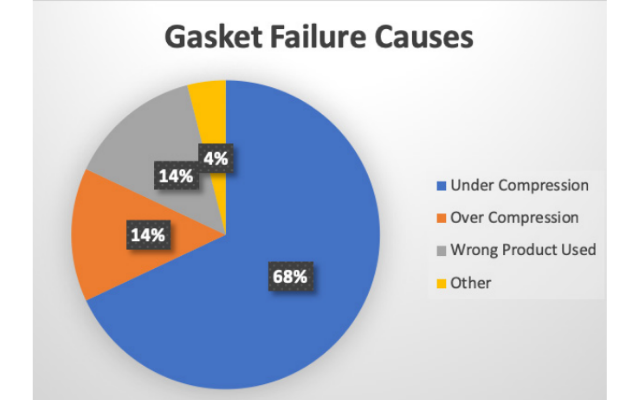

Gasket failures are far too common and in a lot of cases can be categorized into 4 main categories – as this poll explains that was conducted by the FSA on 100 gasket failures. They determined the root cause of the failure causes as:

- Under Compression (68%)

- Over Compression (14%)

- Wrong Product Used (14%)

- Other (4%)

Under Compression can be caused by not tightening the bolt enough to apply the correct load on the gasket due to manual tightening or friction that is unaccounted for or possibly due to gasket relaxation. As you begin to tighten the material it will start to “creep” due to the compressive load being applied. As the gasket thickness decreases, the originally applied load on the bolts will lessen. This is due to the thickness change resulting in a lower gasket stress or compression and can cause a leak due to permeation through the gasket or tangential between the gasket and the flange sealing surface. Additionally, unloading of the gasket can occur due to temperature or pressure cycling which can have the same effect.

Over Compression is caused by too much load on the gasket. This can be caused by not using the correct torque value or perhaps using a tightening tool that you cannot measure the torque, for example an impact gun or cheater bar extension. Over compression reduces the contact area of the gasket and crushes the gasket towards the ID allowing fluid to penetrate the gasket ID thus leading to deterioration of the gasket, damaged flanges and can result in leakage or gasket failure ‑ a huge problem.

When Wrong Product is used, it can become a serious safety issue. The material selected must be capable for the temperature, pressure and media that it is being installed into. If the gasket material is not rated for either the pressure or temperature of the application, this can cause very serious issues such as worker injury or plant down time. Additionally, the gasket must be chemically compatible with the media or the chemical can attack the gasket; causing it to prematurely break down which may cause leakage or even failure.

And lastly, the Other category could be several things, such as using the incorrect gasket size, poor method of cutting, or quite simply, it is somewhat of anomaly and couldn’t be grouped into one of the three categories above.

The good news is, 96% of the above listed failures can be eliminated as they are in YOUR control! By following these few points, you can ensure that your gasket doesn’t have to give you “The Talk”.

- Pick the correct material, verify the pressure,

temperature and media that you will be installing

the gasket into. - Use the proper tightening procedure noted in

ASME PCCC-1. - Lubrication is key, friction is robbing and can

account from more than 50% of the required

torque. - Always use the manufacturers recommended

torque values. If you are unsure, give them a call as

they will be happy you did.

Use a proper tightening tool, such as torque

wrench. - Gasket creep and bolt relaxation happens, be sure

to eliminate this by always remembering to retorque within 4-24 hrs.

Read more about Gasket Installation best practices here.

![Durlon Chemap® filters solve filtration tasks in a simpleand economic way [Case Study]](https://test.empoweringpumps.com/wp-content/uploads/2022/12/Durlon-Chemap®-filters-solve-filtration-tasks-in-a-simpleand-economic-way-Case-Study-7-380x199.png)

Comments