There are many styles of heat exchanger gaskets and most have complicated rib designs or partitions. While some of the most common designs are available to download, Durlon® can provide almost any configuration of heat exchanger type gasket utilizing our Durtec® technology.

- Anywhere fire safety is a concern

- High temperature

- Low available assembly loads

- Heavy vibrations

- Extreme temperature fluctuations

- Remote field applications

- Large diameter asbestos gasket replacement

- Heat exchangers

Advantages:

- Fire Safe – SS316L/Graphite Passed Modified API 607 fire test, 4th Edition

- Blow-out Resistant – Metal core provides excellent resistance to internal pressure spikes

- Reusable – On larger sizes (10” & above)and for special configurations, the core may be refaced with new material and reused providing lower cost of ownership

- Superior Core Technology – Durtec® design can allow for complete replacement of spiral wound and kammprofile gaskets with improved performance and lower life cycle cost

- Easy and safe to handle, easy to install

- Seals tightly with lower bolt loads vs. spiral wounds and kammprofiles

Product Recommendations

Durlon® Kammprofile gaskets have a solid metal core with concentrically serrated grooves machined into the top and bottom faces. The metal core is typically stainless steel, but it can be supplied in various metallurgies as per the customer’s request. The serrated core is covered with soft sealing material and is dependent on the service conditions of the system.

Durlon® Kammprofile gaskets have a solid metal core with concentrically serrated grooves machined into the top and bottom faces. The metal core is typically stainless steel, but it can be supplied in various metallurgies as per the customer’s request. The serrated core is covered with soft sealing material and is dependent on the service conditions of the system.

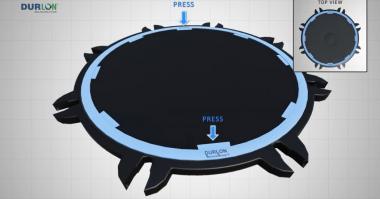

Durlon® Durtec® with Durcore® gaskets are made with a specially engineered corrugated metal core that is bonded on both sides with soft covering layers, typically flexible graphite. The core is produced by patented technology that allows the finished gasket to have the best possible mechanical support function.

Durlon® CFG is a corrugated, flexible graphite gasket material designed for severe service conditions. The proprietary design of the corrugations gives CFG superior sealing and recovery characteristics for tough conditions in the refining, chemical, petrochemical and pulp and paper industries. Durlon® CFG is suitable for service in steam, oil, water, mild alkalis, mild acids, hydrocarbons and solvents.

Durlon® CFG is a corrugated, flexible graphite gasket material designed for severe service conditions. The proprietary design of the corrugations gives CFG superior sealing and recovery characteristics for tough conditions in the refining, chemical, petrochemical and pulp and paper industries. Durlon® CFG is suitable for service in steam, oil, water, mild alkalis, mild acids, hydrocarbons and solvents.

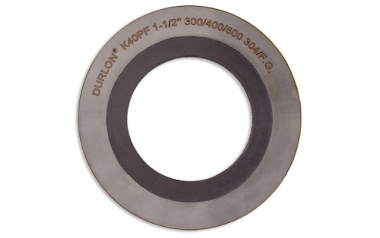

Durlon® SWG Gaskets are made with an alternating combination of a preformed engineered metal strip and a more compressible filler material which creates an excellent seal when compressed. The engineered shape of the metal strip acts as a spring under load, resulting in a very resilient seal under varying conditions. The strip metallurgy and filler material can be selected to seal a wide range of applications. All Class 150 & 300 Durlon® SWG styles have been engineered to precise manufacturing tolerances and utilize optimal winding density that allow for lower stress (bolt load) sealing compared to conventional spiral wound gaskets thus eliminating the need to stock both standard and low stress SWG’s. Style D – Sealing element only consisting of preformed engineered metal and more compressible filler material and commonly used in tongue and groove or male and female flanges.

![Durlon Chemap® filters solve filtration tasks in a simpleand economic way [Case Study]](https://test.empoweringpumps.com/wp-content/uploads/2022/12/Durlon-Chemap®-filters-solve-filtration-tasks-in-a-simpleand-economic-way-Case-Study-7-380x199.png)

Comments