There is nothing worse than being woken up in the middle of the night because of a leak in your piping system… and more often than not, gaskets get the blame!

Application leaks can be dangerous and expensive but at the same time, preventable. Unforeseen expenses due to loss of production increased maintenance costs, and fines could be devastating to a company.

Leaks caused by gasket failures can happen for a variety of reasons:

- Under compression

- Over compression

- Uneven compression

- Re-usage of gaskets

- Chemical Attack

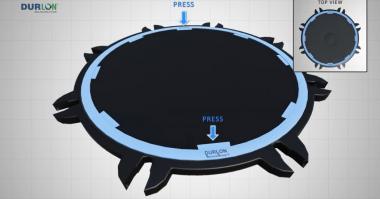

Let’s take a step back and talk about the mechanics of bolting; where a force is applied thru the flange to create a seal. This will compress and densify the gasket, reduce porosity, create a sealing barrier at the gasket ID, and will prevent fluid from penetrating and degrading the gasket.

| Examples of Gasket Failures |

What to look for: | What to expect: | Remedy: |

| OVERTIGHTENING | • Extrusion of gasket from the flange • Irregular-shaped gasket • Inward buckling of Spiral Wound Gaskets that contain inner rings • Imprints on the centering rings |

• Reduced gasket contact area causing the gasket to crush toward the ID • Fluid “pooling” around the ID which can lead to deterioration of the gasket • Damaged flanges |

• Plant Wide Bolting Procedure as referenced in ASME PCC-1 • Gasket Torque Values based on the type of gasket material being used |

| UNDER TIGHTENING | • Little or no flange serration marks • Little change in gasket thickness after being compressed |

• Fluid to penetrate gasket ID leading to deterioration of gasket • Gasket Blowout/Leakage |

• Plant Wide Bolting Procedure as referenced in ASME PCC-1 • Changing bolting material |

| RE-USE/DOUBLE COMPRESSION |

• Multiple compression lines/double patterns | • Gasket Leakage | • Stop the re-use of gaskets |

| CHEMICAL ATTACK | • Gasket Cracking • Softening of Material • Tearing • Erosion of Material • Uneven material discoloration |

• Gasket Leakage | • Review chemical compatibility • Updating storage visual aids to identify different types of gasket materials • Improve storage requirements |

It is important to always contact the gasket manufacturer to ensure the right gaskets are being used in each application. If there is any confusion about the required information for your application, please fill out Durlon’s Gasket Application Data Sheet.

![Durlon Chemap® filters solve filtration tasks in a simpleand economic way [Case Study]](https://test.empoweringpumps.com/wp-content/uploads/2022/12/Durlon-Chemap®-filters-solve-filtration-tasks-in-a-simpleand-economic-way-Case-Study-7-380x199.png)

Comments