With Dynamatic’s longstanding reputation as the world’s leading provider of Eddy Current adjustable speed solutions and Power Test’s position as the industry leader in testing systems, you can be confident that your testing needs will be met. Learn how together we make testing easy by visiting us at EASA: Wisconsin Center; Milwaukee, Wisconsin on June 24-26 in booth 242.

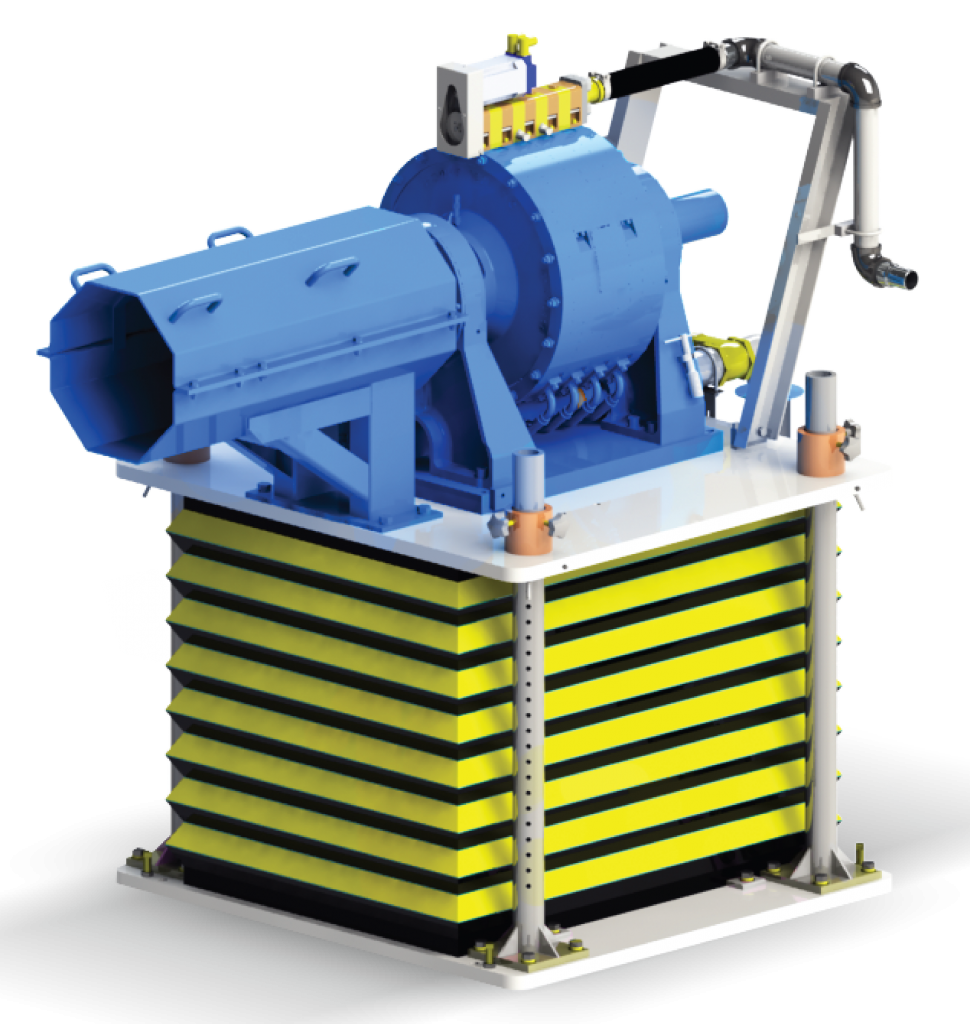

Eddy Current Brakes

Dynamatic offers a wide range of Eddy Current brakes engineered to meet your needs, in both air-cooled and water-cooled designs. These load brakes are ideal for high speed or high power electric motor testing applications. With bi-directional, low inertia capabilities, Dynamatic has an Eddy Current brake guaranteed to meet your testing needs.

Dynamatic offers a wide range of Eddy Current brakes engineered to meet your needs, in both air-cooled and water-cooled designs. These load brakes are ideal for high speed or high power electric motor testing applications. With bi-directional, low inertia capabilities, Dynamatic has an Eddy Current brake guaranteed to meet your testing needs.

- 5000 HP measurement capability

- Maximum speed: 1500 RPM

- Maximum Torque: 63,000 lbs-ft @ 500 RPM

- Rotor Inertia; 9430 lb*ft2

Check out these Additional Resources!

Hydraulic Lift Tables

Power Test’s hydraulic lift table is a variable height mounting platform for the Dynamatic Eddy Current brake and additional Power Test accessories. The lift table provides the dyno a centerline height aligned relative to the electric motor under test. Capable of 6,500lbs capacity and a vertical travel distance of 36”, this lift table allows for versatile testing on a wide range of electric motors.

Power Test’s hydraulic lift table is a variable height mounting platform for the Dynamatic Eddy Current brake and additional Power Test accessories. The lift table provides the dyno a centerline height aligned relative to the electric motor under test. Capable of 6,500lbs capacity and a vertical travel distance of 36”, this lift table allows for versatile testing on a wide range of electric motors.

- Max lifting capacity 60,000 lbs

- 36” centerline adjustment

- 8-Post vertical adjustment guides

- Integrated Drive-Shaft Guard

Check out these Additional Resources!

Additional Testing Accessories Available

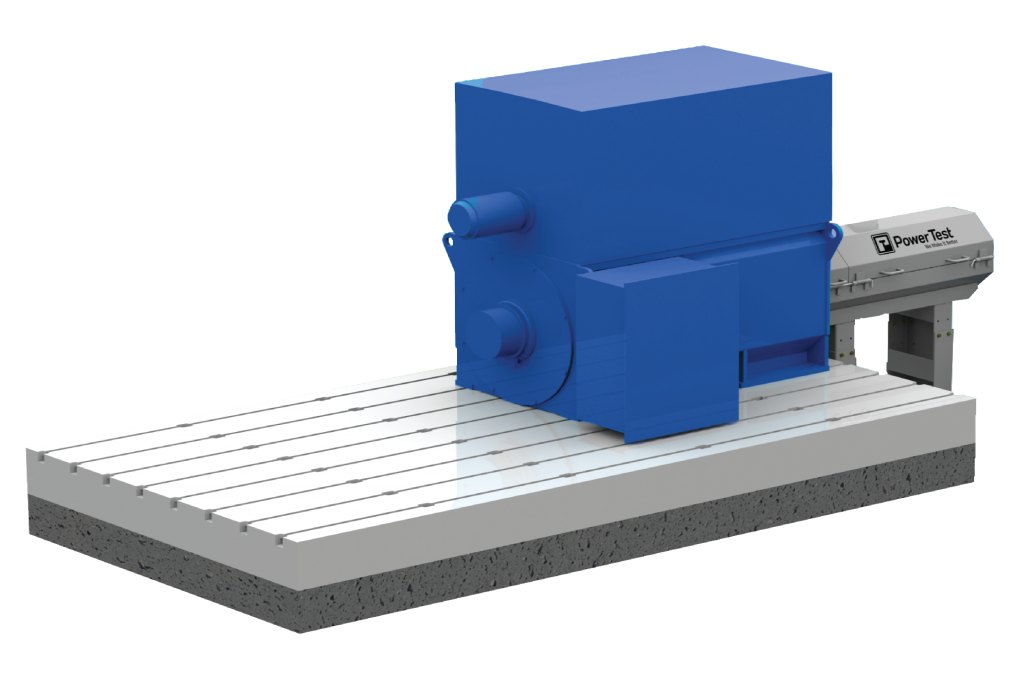

Motor Mount T-Slot Bedplate

This Power Test precision mounting surface provides the foundation for quality electric motor testing with capacities up to 40,000lbs and bedplates machined to a flatness of 0.005”.

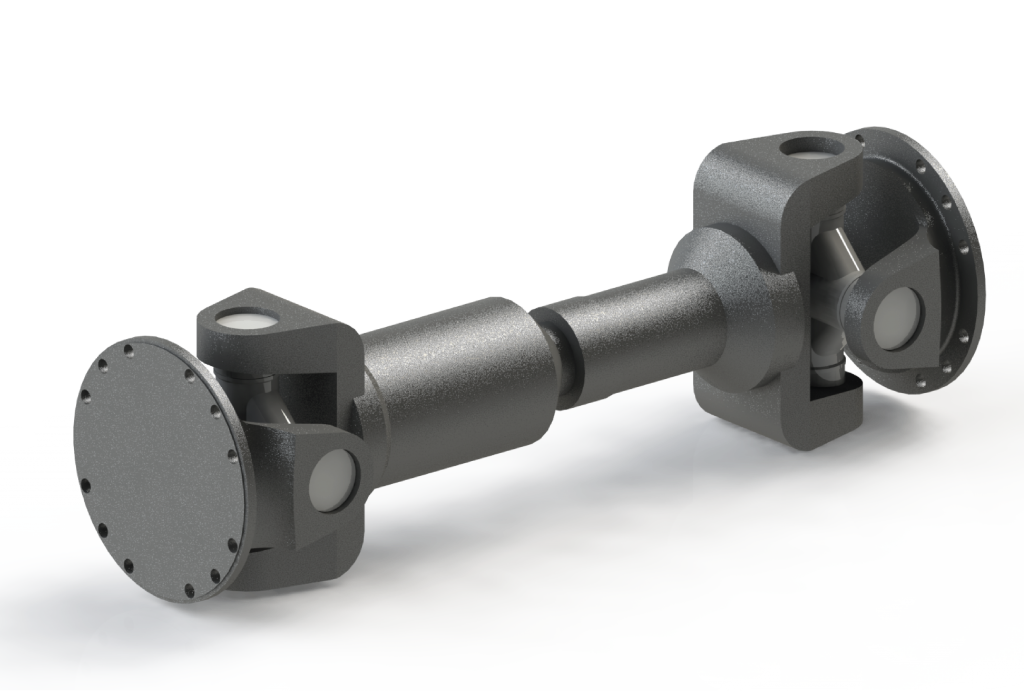

Driveshaft

With multiple driveshaft sizes and capacities up to 63,000 ft-lbs of torque, Power Test ensure you are provided with the optimal testing solution.

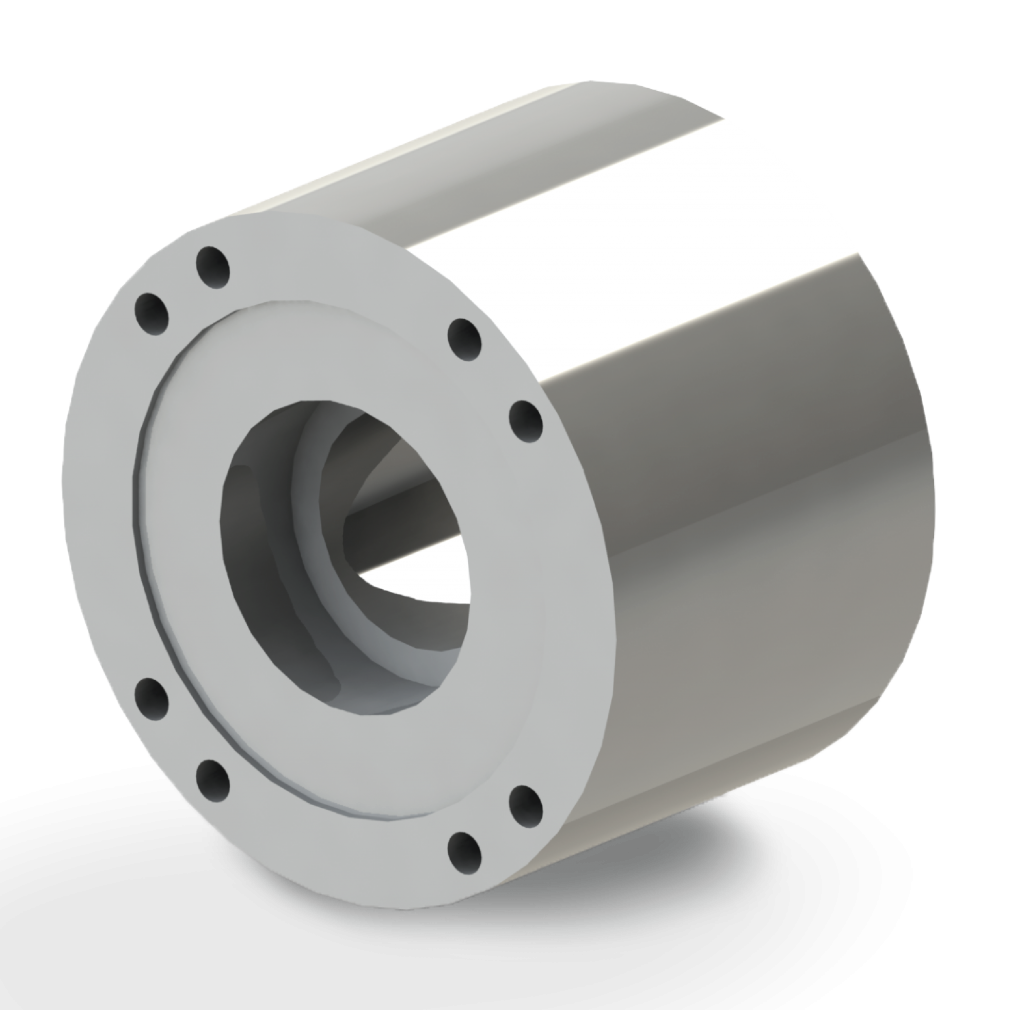

Companion Flange

This rigid coupling is available for high torque electric motor applications and are used to connect driveshaft mounting flange to the dynamometer input shaft.

SEE MORE FROM DYNAMATIC!

Comments