Learn about the conditions inside mechanical seals

It is often the mechanical seal performance data that is the best and earliest indicator of a critical system problem, even when the seal is not the root cause. Plant operators traditionally have had only a few options for:

- Monitoring mechanical seal internal performance

- Accurately understanding how the pump and seal interact

Because of these blind spots, many critical pump performance issues went undetected, until it was too late.

Until now.

RedRaven from Flowserve is a comprehensive internet of things (IoT) platform that mitigates these risks by analyzing equipment performance data with technologies specifically designed for pumps, seals and valves. This gives you a clearer understanding of how to increase the efficiency, productivity and reliability of the equipment you use every day.

Comprehensive updates about equipment conditions

Comprehensive updates about equipment conditions

With RedRaven IoT solutions for seals, you can monitor temperature, pressure level and flow in the seal and support system to understand conditions that may lead to premature failure. These capabilities enable you to:

- Analyze and predict seal performance

- Avoid unplanned downtime

- Proactively plan maintenance

- Optimize processes

Industries and applications:

- Chemical, general industry, oil and gas, pharmaceutical, power and water

- Condition monitoring of all pumps with mechanical seals

- Predictive analytics for critical pumps with mechanical seals

Insights to make well-informed decisions

Insights to make well-informed decisions

Condition monitoring

- See detailed views of the health of mechanical seals through an online cloud-based portal

- Consult with Flowserve seal specialists for analysis when needed

- Proactively identify and address issues before they cause downtime and disruptions through the combination of sensors and an advanced visualization portal

Predictive analytics

Predictive analytics

- Utilize near real-time equipment analysis to predict why critical assets may experience issues and take preventive action

- Identify potential issues earlier than traditional inspection rounds and prevent disruptions before they lead to downtime

How you’ll benefit with RedRaven

- Improved reliability through proactive maintenance

- Enhanced confidence with reliable, data-backed failure analysis

- Reduced time looking for data to use in failure analysis

- Shortened operator rounds to inspect running equipment

- Increased focus on equipment that needs attention

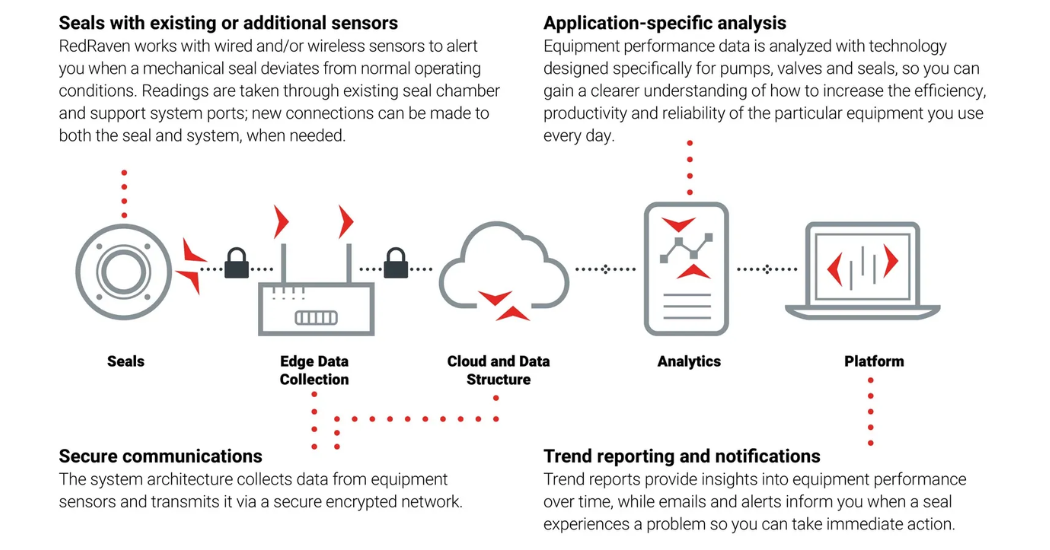

How RedRaven works

Critical data to improve plant performance and reliability

With RedRaven, you’ll gain visibility into more system components. And our global specialists will share insights and recommendations to improve the lifespan of your seals.

As a result, you can avoid unplanned downtime by discovering reliable data about the condition of mechanical seals — along with an understanding of what the data means.

RedRaven alerts you to conditions that could cause failure and recommends corrective actions. As a result, you can be more confident in the reliability of your connected spare equipment to avoid startup failures. With RedRaven, you’ll also save time and money by avoiding unnecessary equipment maintenance while directing resources to troubled assets, equipment and processes that require attention.

Comments