Operators of a municipal water company in northern Germany suspected that a potable water transfer pump was no longer working to its original specification. This water company had been using a vertically configured axially split, single-stage, double-suction pump on potable water transfer service. **Note: this was not a Flowserve pump. The water transfer pump had been originally specified to deliver 800 m3/h (3520 US gpm) at a differential head of 60 m (197 ft) and 81% efficiency. The deteriorated condition of the between bearings, double-suction pump was consuming increasing amounts of energy. This, in turn, led to increased energy costs as well as elevated CO2 emissions.

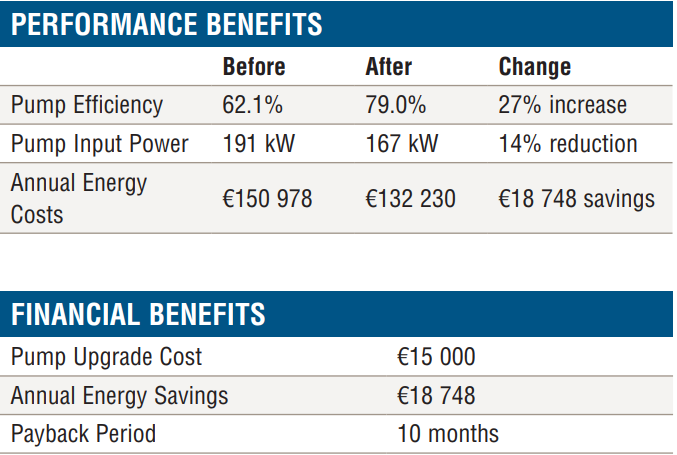

Plant operators suspected its performance had deteriorated significantly. They engaged Flowserve to assess the pump’s performance and implement corrective action. Flowserve engineers conducted an assessment of the pump using thermodynamic performance monitoring techniques, which verified it was operating well below expectations. A complete overhaul of the pump internals resulted in an annual energy savings of approximately €19 000 (assuming 100% load) with a payback of 10 months. This was verified by post-overhaul performance measurements.

Findings

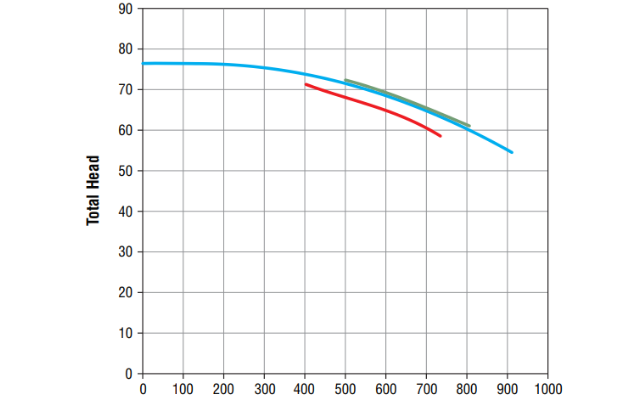

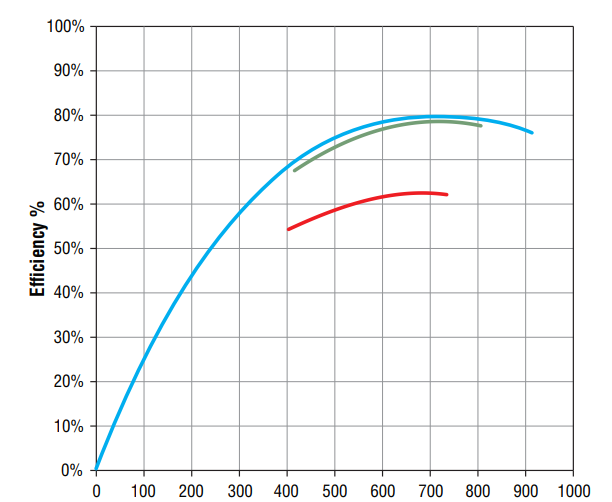

Employing thermodynamic condition monitoring, Flowserve engineers determined the pump was operating at only 62.1% efficiency.

The pump was transported to the Flowserve Quick Response Center in Göhren, Germany, for disassembly and a thorough inspection. They found the pump’s internals exhibited high surface roughness and the wear rings were excessively worn. These conditions were the primary causes of the hydraulic loss.

Corrective Action

Refurbishment included installation of new wear rings to restore the original clearances. The casing and impeller were cleaned and dressed to recover the original hydraulic profile. A refurbished mechanical seal and new bearings were also installed in accordance with good engineering practice. After dynamically balancing the rotating element, the pump was reassembled and pressure tested. It was then transported back to the site for installation and commissioning by Flowserve.

Results

Thermodynamic testing confirmed the refurbished pump was restored to “as new” condition with a 27% gain in hydraulic efficiency and a 14% reduction in power consumption. These improvements produced annual energy savings of approximately €19,000 with a projected payback of 10 months.

Pump efficiency is classically calculated from the flow, head and power. The absence of individual flow meters, however, makes this practice difficult.

Thermodynamic monitoring techniques, on the other hand, use more easily measured parameters – temperature and pressure – to determine pump efficiency. Temperature and pressure probes measure the differences in the internal energy of fluids across the pump. Pump power input is calculated by using a power meter to measure the electrical consumption and factoring in the known motor efficiency. From these measured values of efficiency, differential pressure and pump input power, highly accurate calculations of flow rate can be calculated for an individual pump.

Comments