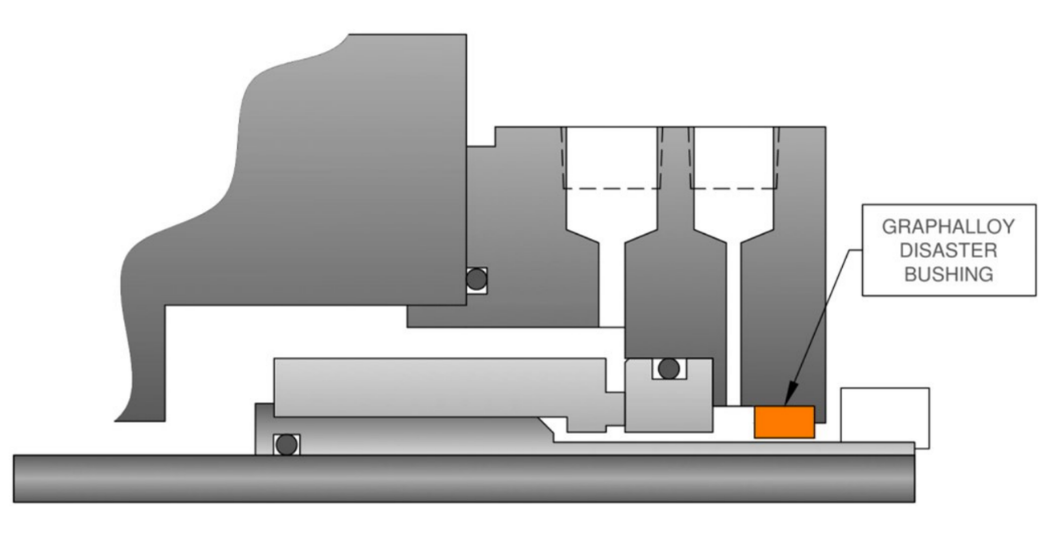

“Disaster Bushings” are used in pumps outside the seal to minimize product leakage to the environment in the event of a seal failure. There are several properties of GRAPHALLOY material that make it an excellent candidate for these applications:

Tighter Clearances: Graphalloy can be used with very tight clearances, allowing any leaked fluid from the seal to be directed through the appropriate drain.

Non-Galling: Graphalloy is solid, uniform material. It is non-galling and self-lubricating. It is not a surface coating and therefore will not chip off. As Graphalloy is the “sacrificial part”, if the shaft comes in contact, it will not be damaged.

Low Coefficient Of Thermal Expansion: Thermoplastics or metal wear parts used for “disaster bushings” need to be designed to handle a rapid rise in temperature from hot service fluid coming in contact or from touch-off against the shaft. This means designing with wider clearances, partially defeating their purpose. Graphalloy’s low coefficient of thermal expansion relative to metal or thermoplastic means it won’t expand under the high temperatures and can be designed with extremely tight clearances, resulting in more effective leak protection.

GRAPHALLOY works in temperatures ranging from -450°F to over 1000°F (-267°C to over 540°C). It is corrosion resistant and performs in conditions where metal or polymer wear parts fail. Our US-based manufacturing facility can install the Graphalloy for you in your own metal rings or can provide a turnkey ring assembly ourselves.

Learn more about GRAPHALLOY® Parts for Pump Reliability & Safety!

![Durlon Chemap® filters solve filtration tasks in a simpleand economic way [Case Study]](https://test.empoweringpumps.com/wp-content/uploads/2022/12/Durlon-Chemap®-filters-solve-filtration-tasks-in-a-simpleand-economic-way-Case-Study-7-380x199.png)

Comments