The use of graphite alloy bearings made it possible to improve water quality by eliminating the need for oil lubrication in a 1000-foot deep-set water supply system. The Department of Hawaiian Homes (DHH) wanted to eliminate oil contamination while overhauling a deep well pump used as a primary potable water source for the island of Molokai. Bearing failures have often been experienced when systems of this depth are converted to water lubrication because of the difficulty of maintaining lubrication during pump startup. In this application, the consulting engineers at Roscoe Moss Inc. avoided these problems by switching from bronze to graphite metal alloy bearings that withstand run-dry conditions. The result has been four years of trouble-free operation.

Molokai is the fifth-largest island in the Hawaiian archipelago: It is 260 square miles (42 km2) in area, 38 miles (61 km) long, and 10 miles (16 km) wide at its widest point. The population is estimated at 7000 residents, half of whom live in or near the principal town of Kaunakakai. The DHH, a unit of the Hawaii state government, operates the water supply system on the island including the Kualapuu wells, one of the primary sources of potable water on the island.

Request for Bids

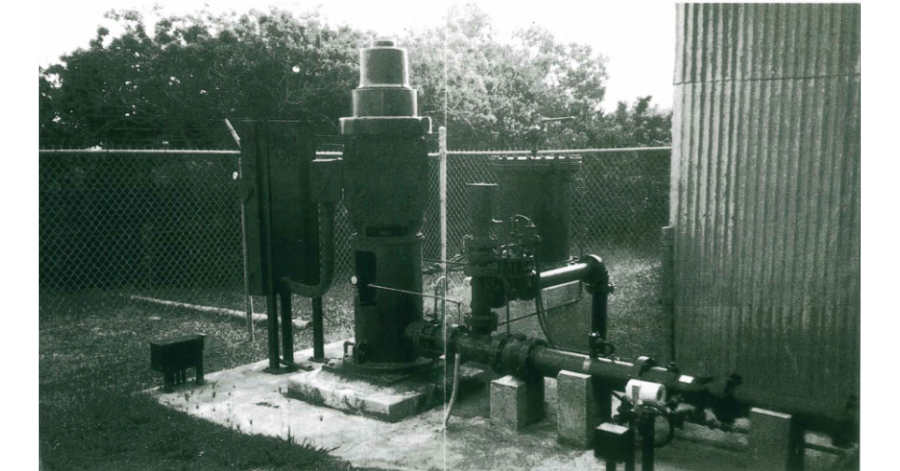

In 1994, the DHH requested bids for two new lineshaft pumping units for these wells. Well No. 1 pump required a complete unit including motor and dis-charge head assembly, while the exist-ing 300 hp motor and discharge head assembly for Well No. 2’s pump was in good condition and could be reused. The existing pumps used enclosed line-shafts and oil-lubricated bronze bush-ings throughout. Each pump was 1000 feet long with the water level approximately 950 feet below the mounting elevation. Bearings were lubricated by dripping a lightweight turbine oil into the top of the enclosing tube from a solenoid oiler, which stops oil flow when the pump is not operating. The oil descended by gravity from bearing to bearing and escaped into the well through drain ports just above the top impeller that were sealed against leakage.

This approach provided excellent lubrication, but is rapidly becoming obsolete due to water quality and environmental concerns. As with most recent water supply projects, the DHH specified in this case that the stuffing box assembly be converted from oil to water lubrication to eliminate oil contamination of the water supply. A simple alternative was to convert from turbine oil to a food-grade oil; how-ever, present-day food-grade oils are expensive and provide such poor lubricating properties that seize-ups are frequent in applications where they are employed. The use of food-grade lubricants was ruled out here because the water provided by these wells would be expensive to replace, even for short periods of time.

Consideration of Alternatives

Roscoe Moss engineers, working with DHH’s consulting engineer, Clifford Jamile, investigated various water-lubricated bearing approaches. An open lineshaft running in cut-lass rubber bearings can be lubricated and cooled by introducing consider-able quantities of water through a port in the discharge head for a period of 10 to 15 minutes prior to energizing the pump. However, frequent failures have been seen in water-lubricated open lineshafts with rubber bearing construction in deep-set applications of 600 feet and higher. Water is a good lubricant; however, the loss of water during the pre lubrication period just prior to pump startup will cause Gut-less rubber bearings to fail in a matter of seconds once the motor is energized. Bearing failures require expensive maintenance that forces the pump to go out of service for up to a week. This means that the bearings must be continually infused with water during the startup and shutdown phases. In deep-set applications, air rushing up the shaft during the startup phase atomizes the water stream in the upper portion of the well, preventing proper lubrication. In addition, adequate lubricating water also may not be available in certain situations such as during a storm or breakdown.

Another approach is to substitute water for oil in a standard enclosed lineshaft using threaded bronze tube connectors and bearings. This type of system is used extensively in short-coupled water supply applications, but it typically fails quickly in deep-set applications above 600 feet for the same reasons that open lineshaft systems fail. In an effort to avoid these problems, a scheme has been developed in which water is introduced at various levels in the well. This approach provides more consistent lubrication but is quite expensive and still subject to failure during an interruption of the water supply.

Graphite-Metal Bearings

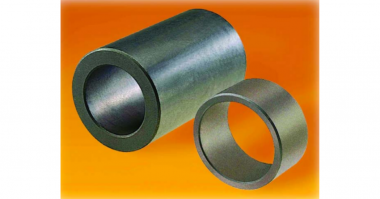

In an effort to solve this problem, Roscoe Moss engineers evaluated a wide range of run-dry bearing materials. These tests included trials of several alternative synthetic nylon bearing materials. Some improvements were seen over bronze and rubber materials but the new materials still did not exhibit the ability to consistently withstand the demanding run-dry conditions of the application. Then an engineer heard about graphite-metal alloys that take advantage of the special properties of graphite. A graphite structure can be compared to a deck of cards with individual layers able to easily slide off the deck. This phenomenon gives the material an excellent self-lubricating ability. External lubricants are not necessary. The graphite matrix can be filled with a variety of impregnants to enhance chemical, mechanical, and tribological properties.

Roscoe Moss engineers identified a graphite-alloy material that had already been successfully used in several deep-set well applications, GRAPHALLOY graphite-metal alloy from Graphite Metallizing Corp., Yonkers, New York. This self-lubricating bearing material requires no grease or oil, survives run-dry conditions, and eliminates galling and seizing in hot and dry conditions. The material works at temperatures up to 1000°F (525°C), where oil-based lubricants burn off or oxidize and plastics fail. It maintains its integrity even when submerged in hostile liquids such as acids, alkalies, hydrocarbons, black liquor, and liquid gases. The material provides a constant, low coefficient of friction rather than just a surface layer, helping to protect against catastrophic failure. Lubrication is maintained even during linear motion; lubricant is not drawn out and dust is not pulled in.

Proposal and Design

Roscoe Moss’s proposal submitted to the DHH stated that the additional expenditure for the graphite bearings would provide a value that far exceeded the bearing insert cost by extending the life of the machine and providing a positive method of lubricating the lineshaft, with or without water flush. The department accepted the company’s proposal.

Well Pump No. 1 used a Layne and Bowler 1ORKEH-22 stage bowl assembly with 8-inch columns, 3-inch enclosing tube, and 1’Y16-inch shaft diameter. This pump was rated for 600 gallons per minute (gpm) with a field head of 1080 feet. Well Pump No. 2 used a Layne and Bowler 11 DWH-19 stage bowl assembly with 8-inch columns, 4-inch enclosing tube, and 1’Y16-inch shaft diameter. This pump used the existing 300 hp motor. This pump was rated for 800 gpm with a field head of 1080 feet.

Bearing Implementation

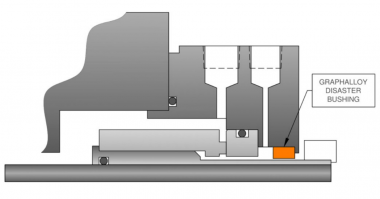

Installing the graphite alloy bearings required minimal modifications to the existing enclosure. Roscoe Moss engineers provided their dimensional constraints to Graphite Metallizing, which in turn designed the new bearings that are fitted in SAE 660 bronze tube connectors located at 5-foot intervals throughout the length of the lineshaft. Every other tube connector contains a full bearing and the other connectors contain a half bearing. The existing 415 stainless steel lineshaft did not require modification.

The smaller 200 hp pump used for Well 1 was the first to be completed and installed. This unit was started in September 1995 and was run 24 hours a day until the second pump was installed. The larger pump for Well 2 was delivered and installed in May 1996 with a final walk-through inspection in June. Since that time, only one of the two pumps has been run at any given time due to power restrictions on the island. The smaller 200 hp pump is run during peak hours and the larger 300 hp pump during off-peak hours.

This installation has delivered trouble-free service since installation. A standard lubrication system was provided; however, in emergency situations, operators restart the pump without any lubrication. The success of this application has led to the installation of graphite alloy bearings in several other open and enclosed lineshaft applications in Hawaii by Roscoe Moss. These include an enclosed lineshaft water flush system owned by the Hawaiian Electric Co., an enclosed lineshaft potable water supply owned by the Maui Board of Water Supply, and an open lineshaft potable water system owned by the Hawaii Department of Water Supply. Each of these systems has provided the same trouble-free service as the original installation in Molokai. connectors and bearings. This type of system is used extensively in short coupled water supply applications, but it typically fails quickly in deep-set applications above 600 feet for the same reasons that open lineshaft systems fail. In an effort to avoid these problems, a scheme has been developed in which water is introduced at various levels in the well. This approach provides more consistent lubrication but is quite expensive and still subject to failure during an interruption of the water supply.

Graphite-Metal Bearings

In an effort to solve this problem, Roscoe Moss engineers evaluated a wide range of run-dry bearing materials. These tests included trials of several alternative synthetic nylon bearing materials. Some improvements were seen over bronze and rubber materials but the new materials still did not exhibit the ability to consistently withstand the demanding rundry conditions of the application. Then an engineer heard about graphite-metal alloys that take advantage of the special properties of graphite. A graphite structure can be compared to a deck of cards with individual layers able to easily slide off the deck. This phenomenon gives the material an excellent self-lubricating ability. External lubricants are not necessary. The graphite matrix can be filled with a variety of impregnants to enhance chemical, mechanical, and tribological properties.

Roscoe Moss engineers identified a graphite-alloy material that had already been successfully used in several deep-set well applications, GRAPHALLOY graphite-metal alloy from Graphite Metallizing Corporation, Yonkers, New York. This self-lubricating bearing material requires no grease or oil, survives run-dry conditions, and eliminates galling and seizing in hot and dry conditions. The material works at temperatures up to 1000°F (525°C), where oil-based lubricants burn off or oxidize and plastics fail. It maintains its integrity even when submerged in hostile liquids such as acids, alkalies, hydrocarbons, black liquor, and liquid gases. The material provides a constant, low coefficient of friction rather than just a surface layer, helping to protect against catastrophic failure. Lubrication is maintained even during linear motion; lubricant is not drawn out and dust is not pulled in.

Proposal and Design

Roscoe Moss’s proposal submitted to the DHH stated that the additional expenditure for the graphite bearings would provide a value that far exceeded the bearing insert cost by extending the life of the machine and providing a positive method of lubricating the lineshaft, with or without water flush. The department accepted the company’s proposal.

Well Pump No. 1 used a Layne and Bowler 1ORKEH-22 stage bowl assembly with 8-inch columns, 3-inch enclosing tube, and 1’Y16-inch shaft diameter. This pump was rated for 600 gallons per minute (gpm) with a field head of 1080 feet. Well Pump No. 2 used a Layne and Bowler 11 DWH-19 stage bowl assembly with 8-inch columns, 4-inch enclosing tube, and 1’Y16-inch shaft diameter. This pump used the existing 300 hp motor. This pump was rated for 800 gpm with a field head of 1080 feet.

Bearing Implementation

Installing the graphite alloy bearings required minimal modifications to the existing enclosure. Roscoe Moss engineers provided their dimensional constraints to Graphite Metallizing, which in turn designed the new bearings that are fitted in SAE 660 bronze tube connectors located at 5-foot intervals throughout the length of the lineshaft. Every other tube connector contains a full bearing and the other connectors contain a half bearing. The existing 415 stainless steel lineshaft did not require modification.

The smaller 200 hp pump used for Well 1 was the first to be completed and installed. This unit was started in September 1995 and was run 24 hours a day until the second pump was installed. The larger pump for Well 2 was delivered and installed in May 1996 with a final walk-through inspection in June. Since that time, only one of the two pumps has been run at any given time due to power restrictions on the island. The smaller 200 hp pump is run during peak hours and the larger 300 hp pump during off-peak hours.

This installation has delivered trouble-free service since installation. A standard lubrication system was provided; however, in emergency situations, operators restart the pump without any lubrication. The success of this application has led to the installation of graphite alloy bearings in several other open and enclosed lineshaft applications in Hawaii by Roscoe Moss. These include an enclosed lineshaft water flush system owned by the Hawaiian Electric Co., an enclosed lineshaft potable water supply owned by the Maui Board of Water Supply, and an open lineshaft potable water system owned by the Hawaii Department of Water Supply. Each of these systems has provided the same trouble-free service as the original installation in Molokai.

Originally Published in Water Well Journal

Read more about Graphalloy bearings.

Comments