Author: Heinz P. Bloch, P.E.

A listing of the four or five worst enemies of proper and reliable lubrication will include lubricant contamination, viscosity, and application deficiencies. These three parameters are interrelated. For instance, water entering as an outright contaminant or in the form of air saturated with moisture often causes additive depletion. The lubricant then rapidly degrades and bearings fail prematurely. Water can also act as the catalyst for sludge formation and often has an undesired effect on viscosity. Oil rings tend to malfunction in oils of inappropriate viscosity.

Profitability-minded plants pay attention to these facts and thoughtfully manage all of their lubrication practices, including oil storage and oil transfer. With thoughtful lube management they reap substantial benefits from the enhanced pump reliability that results.

How bad is water contamination?

Even relatively small amounts of water contamination tend to affect bearing performance. The life of an antifriction bearing with even as little as 100 ppm of free water in the lubricant (1 teaspoon of water in 13 gallons of oil) will be only 40% of the life of the same bearing with 25 ppm free water present (Ref. 1). Also, most major bearing manufacturers have published estimates on the effects of lubricant contamination (Ref. 2).

Considerable time is often wasted in arguments over how much water should be tolerated in pump bearing housings. It would be far more productive to locate the source of water intrusion and to cut off the source. Certainly, the amount of water drained from the pump bearing housing in Fig. 1 is totally unacceptable.

In all instances, getting rid of unsuitable transfer containers (Fig. 2) must be made one of the first orders of business.

Fig 3: Careless handling of an approved transfer container can still cause extreme particulate contamination (Ref. 3)

Galvanized oil transfer containers are frequently attacked by certain lube oil additives. Good lube management practices mandate the use of approved dispensing containers. Of course, even the best purpose-designed plastic containers can be defeated by careless handling. This is illustrated in Fig. 3.

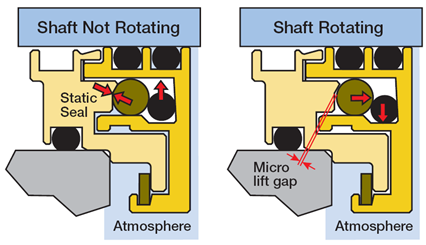

Lube oil contamination can be kept in check in several ways. Modern bearing protector seals (Figure 4) will prevent the ingress of water, steam and other airborne contaminants. Either single-face (face-contacting) magnetic seals or advanced rotating labyrinth style (non-contacting) bearing protector seals are available. Both types make much economic sense and merit consideration in new and existing (retrofit-to-upgrade) installations.

References

- Bloch, Heinz P.; “Machinery Reliability Improvement", 3rd Edition (1998) Gulf Publishing Company, Houston, Texas; ISBN 0-88415-661-3

- SKF USA, Inc., Kulpsville, Pennsylvania, (1991), General Catalog 4000 US

- Fluid Defense Systems, Montgomery, Illinois 60538

- Bloch, Heinz P.; “Petrochemical Machinery Insights” (2017) Elsevier Publishing, Oxford, UK and Cambridge, MA; (724 pages), ISBN 978-0-12-809272-9

Comments