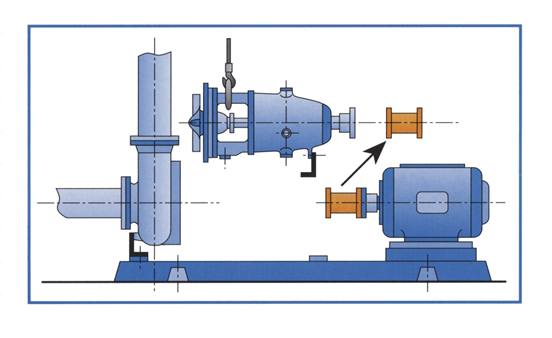

Many process pumps are designed and constructed to facilitate field repair. On the so-called back pull-out pumps (see illustration, also Ref. 1), shop maintenance can be performed while the casing and its associated suction and discharge piping are left undisturbed.

The impeller, pump shaft and bearings remain with the power end which is simply lifted up and removed for refurbishment, if needed. A spacer coupling is used; disc-pack couplings are much preferred over certain cheap and therefore popular elastomer-in-torsion couplings.

Although costing more initially, well-designed disc-pack couplings save money in the long run. In to get a long run, failure avoidance and safety are the ever-present key goals of reliability-focused users (Ref. 2).

Because this is the fundamental definition of reliability, it, like truth, will never change. Reliability will touch on a number of issues with process pumps; these issues and their solutions will be explained in many future postings. In particular, Ref. 3 will both highlight and summarize much of this in a 724-page book.

References

- Bloch, Heinz P. and Allan Budris; “Pump User’s Handbook: Life Extension,” 4th Edition, (2014), Fairmont Publishing, Lilburn, GA, ISBN 0-88173-720-8

- Bloch, Heinz P.; “Pump Wisdom: Problem Solving for Operators and Specialists”; (2011), Wiley & Sons, Hoboken, NJ; ISBN 9-781118-04123-9

- Bloch, Heinz P.; “Petrochemical Machinery Insights,” (2016) Elsevier Publishing, Oxford, UK, and Cambridge, MA, ISBN 978-0-12-809272-9

Comments