Challenge

Dry motor submersible pumps use a robust shaft and bearing design to limit shaft deflection from harsh pumping conditions, including solids. A VFD-driven dry motor submersible pump at a wastewater treatment center was experiencing premature bearing failure due to EDM machining as a result of harmful stray shaft currents. The bearing failures reduced the “stiffness” of the shaft assembly and lead to reduced mechanical seal life and excessive wear to the pump wet end along with unpredictable reliability and constant removal and replacement of the bearings and seals.

Solution

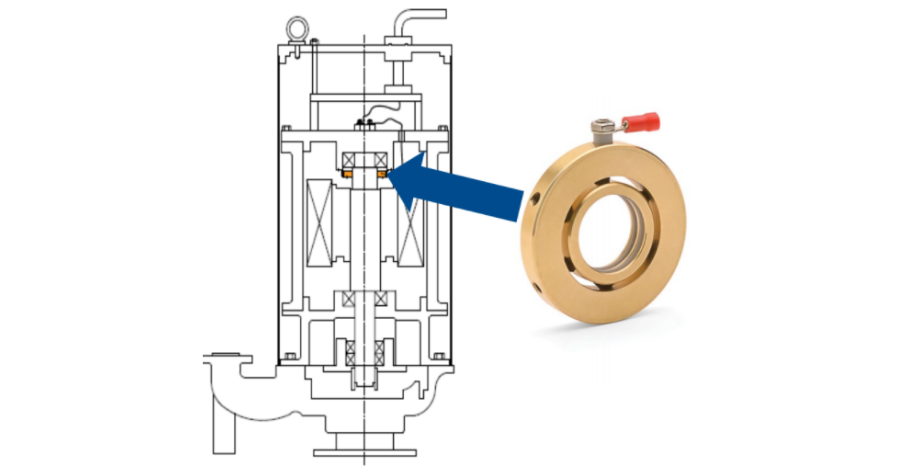

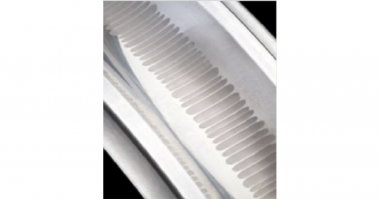

An Inpro/Seal® CDR ® (Current Diverter Ring) was installed inside the motor to mitigate stray shaft currents. The CDR, constructed of solid corrosion resistant and highly conductive bronze, utilizes proprietary carbon filaments around the ring to divert the stray shaft currents away from the bearings to the ground – preventing bearing damage.

Submersible pump

Result

Inpro/Seal CDRs were installed on 25 submersible pumps in 2016. After proving effective against stray shaft currents, an additional 50 CDRs were installed. The CDRs have perform as expected with zero maintenance requirements since installation.

Comments