Basic proper piping practices can lead to extended pump life with minimal maintenance. Following these simple guidelines when installing your piping can lead to less headaches and downtime.

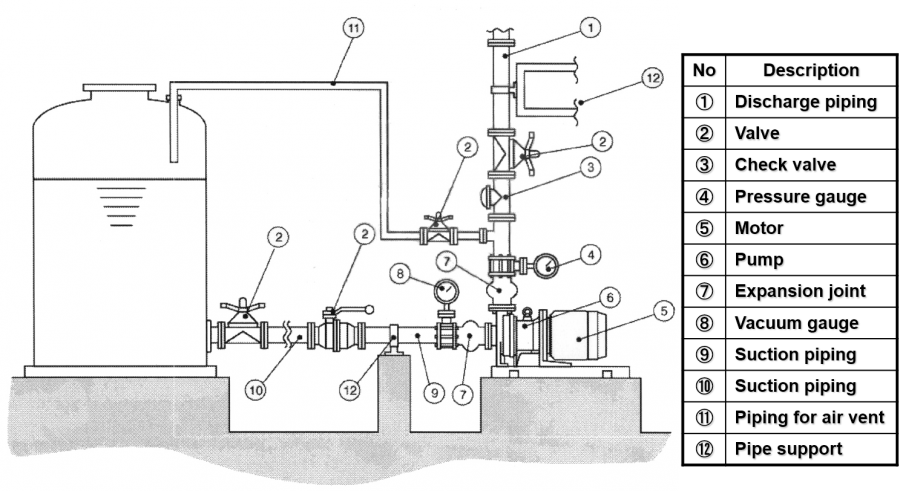

Be sure your suction piping is below your liquid level ensuring flooded suction conditions to the

pump at all times.

- Baffle the interior of your supply tank to prevent swirling and to reduce the flow speed

- Keep the supply tank free from debris that can enter the pump

- Be sure the inlet piping to the pump is the same or a larger diameter than the pump inlet

- Keep the inlet piping as short as possible but no shorter than 10x the pipe diameter (example a 2” pump suction should have 20” of straight pipe heading into the pump inlet)

- Minimize the number of joints on the suction line and be sure all joints are completely sealed

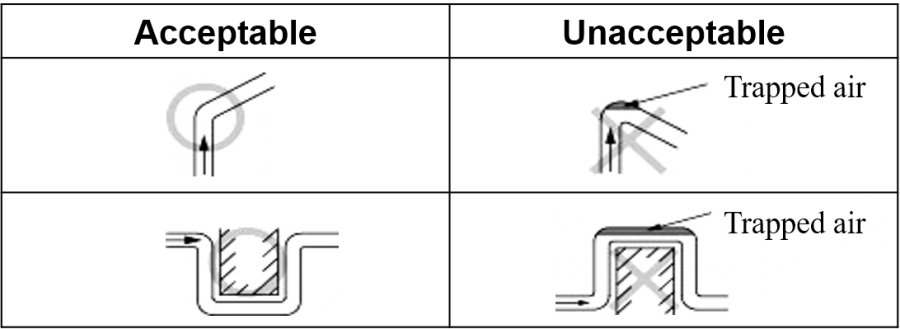

- Avoid areas where air pockets can form (attached)

- Install a gate valve on the pump discharge to prevent overload during startup

- Install an air vent valve on the discharge to purge any air on the discharge upon startup

Pump longevity and minimal maintenance it the goal of every operator. Following these simple practices when designing your system will lead to extended pump life. Iwaki America has over 65 years in the design and manufacturing of centrifugal sealless pumps. Visit iwakiamerica.com for more information.

Pump longevity and minimal maintenance it the goal of every operator. Following these simple practices when designing your system will lead to extended pump life. Iwaki America has over 65 years in the design and manufacturing of centrifugal sealless pumps. Visit iwakiamerica.com for more information.

Comments