A highly corrosive and toxic chemical with strong disinfecting properties, Sodium Hypochlorite plays an ever-increasing role in many industries. However, its corrosive nature and tendency to release tiny gas bubbles that can permeate non-metallic pumps poses a major challenge to conventional pumping techniques. Iwaki has over 50 years of experience successfully pumping Sodium Hypochlorite & many other aggressive chemicals. It’s all in the Magnets

Iwaki’s MDM Pumps exclusively utilize the highest grade Samarium Cobalt (Sm2-Co17) Magnet capsules for better torque at elevated temperatures and proven superior chemical resistance.

Comparatively, competitive magnetic designs use less expensive Barium Ferrite or Neyodimium Iron Boron (Nd-Fe-B) magnets with little or no corrosion resistance to Sodium Hypochlorite. These low-end magnets typically react with their environment, frequently with disastrous results.

Comparatively, competitive magnetic designs use less expensive Barium Ferrite or Neyodimium Iron Boron (Nd-Fe-B) magnets with little or no corrosion resistance to Sodium Hypochlorite. These low-end magnets typically react with their environment, frequently with disastrous results.

- Manufacturer “A” utilizes an unprotected Nd-Fe-B magnet assembly that is highly susceptible to corrosion by chlorine gas permeation.

• This generally shows up as splitting along the length of the magnet capsule from magnet swelling. Long-term Nd-Fe-B exposure to Sodium Hypochlorite can cause the magnet assembly to lock-up and de-couple, fracturing from differential expansion of the surrounding molded materials.

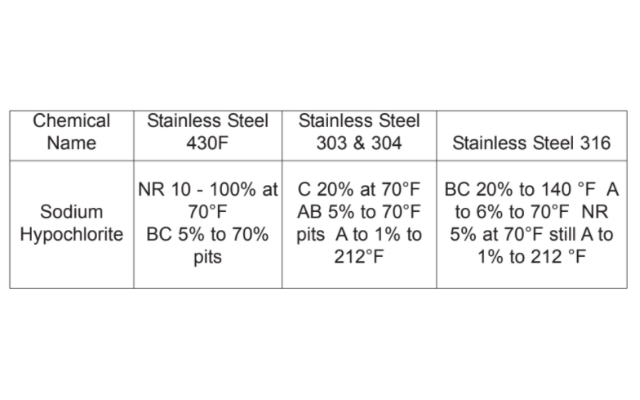

• Manufacturer “B” also utilizes a cheaper Nd-Fe-B magnet assembly, protected with a 316 SS shield. Note, 316 SS is not recommended for use in pumping Sodium Hypochlorite solutions.

• In addition, this 316 SS shield produces eddy current losses and extra heat that can degrade the quality of Sodium Hypochlorite.

A (2) two-year warranty for Sodium Hypochlorite applications!

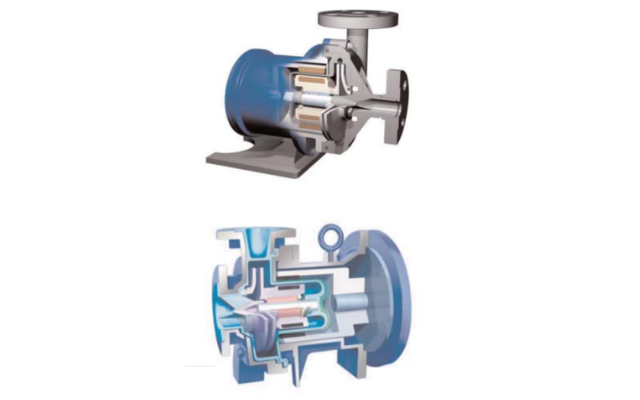

Sealless Solutions for Safe Chemical Handling

Pumping Sodium Hypochlorite (NaClO) & Caustic Soda (NaOH) should be done with great care and consideration. Since NaClO is highly corrosive and potentially toxic, precautions should be taken to eliminate any potential leak paths. Given Caustic Soda’s likelihood of abrasive solids precipitation with contact with air, it is known to cause leakage in single mechanical seals, often leading to installation of costly, maintenance-intensive double mechanical seals.

Iwaki MDM & MX-F Sealless Pumps offer the following

Iwaki MDM & MX-F Sealless Pumps offer the following

advantages over mechanically- sealed designs:

- No dynamic seals

• Minimized maintenance

• Lower cost of ownership

• Increased reliability

• Elimination of seal flush systems

• Minimized number of parts

• Maximized safety

• More compact design

• Elimination of the single greatest failure mode the seal

Only The Best Available Materials of Construction Iwaki MDM & MX-F Sealless Pumps are manufactured with the highest quality materials:

- Teflon pump casings & impellers for superior chemical resistance & high temperature processing (up to 300°F for MDM designs)

• Fiberglass pumps require cost-intensive curing processes and are still limited to 150°F/180°F

• High Purity Ceramics and Silicon Carbide to handle abrasive caustic services

• Virgin PFA & Alpha Sintered Silicon Carbide eliminate ionic contamination and allow for the highest purity bleach production & extended shelf-life for your products.

• High Density Carbon Bearings & Thrust Plates protect your process during extended Dry-Run situations.

Don’t settle for cheap imitations, stick with Iwaki, the leader in Sealless Pump Technology

Comments