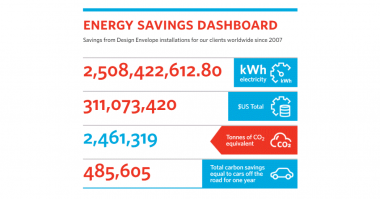

Using the packaged system recommended by Armstrong Fluid Technology, designers were able to reduce the pump power requirements by 70% to dramatically increase energy efficiency.

Shorewood Printing is a commercial printer for the cosmetics, home video, music, and software markets. Now part of International Paper, the company operates a facility

in Danville, Virginia.

In 2009, Shorewood approached Southern Air, a Virginia-based design-build contractor that specializes in HVAC installations, for help in upgrading their industrial make-up air/plant cooling systems.

One of the challenges associated with the project was the lack of space. The building had no available space for a proper equipment room. The designs called for installation of boilers generating 10,000,000 BTUs in a room no more than 11 feet wide. So Shorewood needed a cooling solution that used minimal floor space.

The initial plans were to use constant speed Vertical In-Line pumps in a duty/standby configuration – a 100hp CW pump and a 15hp HW pump – but that was later revised to use variable-speed pumps. Designers ended up combining the HW Pre-heat and Reheat to reduce the installation to 6 Design Envelope IVS vertical inline pumps.

A lack of sensors in the system presented an added challenge. Designers briefly considered using Lonworks, but chose to use the Armstrong Design Envelope sensorless technology instead.

SE Burks Sales Company provided the new equipment from Armstrong Fluid Technology to Southern Air, which included four 4300 Design Envelope IVS pumps, two 4302 Design Envelope IVS Dual Arm pumps, and IVS sensorless controls.

Selecting a Design Envelope pump simplified the installation and gave the facility operators fingertip control over pump operation, plus integrated variable-speed technology that would automatically adjust pump speed to match cooling system requirements.

The project was completed in November 2009. Overall the equipment and installation costs stayed within budget, and because of the decision to use Design Envelope pumps, installation labor hours were reduced below the original estimate.

Facility operators at Shorewood found the Armstrong VIL solution very effective, particularly the floor space savings provided by the integrated, pump-mounted drives. Perhaps the most dramatic aspect of the installation was the fact that designers could stack the pumps with the control panels facing a walkway.

The advanced controls of the Armstrong Design Envelope pumps allowed for integration into the existing BAS system, so the monitoring and control of the pumps was easy and convenient.

“The savings delivered to Shorewood have been amazing,” declares Chuck Lerch from SE Burks Sales Company, “The Design Envelope approach to sizing allowed us to substantially reduce the pump horsepower from from 115hp to less than 29.5hp.”

Armstrong’s Variable Speed Retrofit Solution To Be Featured at AHR Expo 2017

For more information about Design Envelope technology, visit www.armstrongfluidtechnology.com.

Comments