The Echowater Project is upgrading the existing Sacramento Regional Wastewater Treatment Plant located in Elk Grove, California. The facility is being renovated in order to meet the new treatment requirements set by the Central Valley Regional Water Quality Control Board (CVRWQCB) and State Water Resources Control Board (SWRCB).

The project

Regional San was issued stringent new treatment requirements in 2010 from the State of California to make significant upgrades to the wastewater treatment plant. The new system, with a targeted completion date in 2023, will produce cleaner water for discharge to the Sacramento River, as well as the potential reuse of recycled water (e.g. for landscape and agricultural irrigation).

This major upgrade has been given the name of “EchoWater Project” to reflect how it will utilize and process the wastewater, returning it to a clean, natural state – in the same manner that an “echo” returns to its source of origination. Once completed, Regional San will be in compliance with its regulatory permits and improve water quality by resulting in a 99 percent reduction in ammonia discharged to the Sacramento-San Joaquin River Delta. Ultimately, EchoWater will be capable of meeting the region’s needs and protecting the waterways for generations to come.

The EchoWater Project, which is one of the largest public works projects in Sacramento’s history, comprises structures from several other projects, including Biological Nutrient Removal (BNR) tanks, granular media filters, disinfection basins, pumping stations, electrical buildings, and support facilities. The BNR process will eliminate nearly all ammonia and most nitrate, while filtration processes will help remove smaller particles and pathogens from the effluent. Enhanced disinfection will also be implemented to inactive pathogens.

Key Success Factors

Meeting rigorous reliability and energy efficiency requirements, KSB pumps and mixers serve the heart of the plant. The KSB equipment, supplied in three different project phases, will play a critical role in achieving the stringent requirements issued by the State of California. Additionally, the experience and expertise of KSB and KSB manufacturer representative, G3 Engineering, greatly contributed in the selection process for this complex and highly demanding project.

| KSB Equipment | Applications | Qty. |

| KRT Pumps | Nitrifying Sidestream Waste Activated Sludge, Stormwater, Mixed Liquor |

20 |

| Biological Nutrient Removal Wet Well Drainage, Primary Effluent Jetting, Bay Drainage, Gravity Diversion Drainage, CFE Drainage, Ox6 Scum Pumps, PE Splitting Scum Pumps, Deoxygenation Scum Pumps, RAS Pre-Anoxic Scum Pumps, Stormwater, Mixed Liquor Flow Splitting Scum Pumps |

27 | |

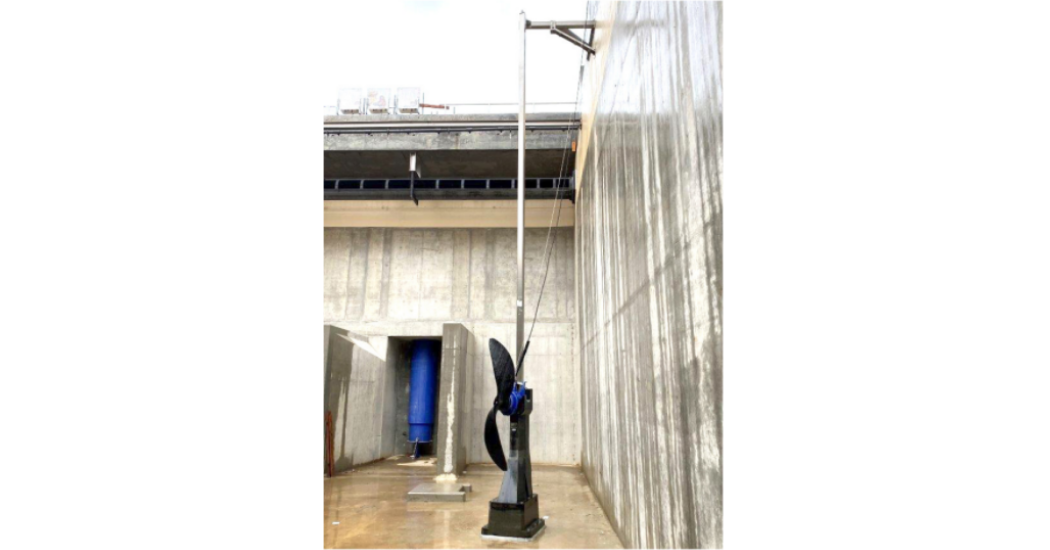

| Amaprop Mixers | Mixed Liquor Fermenter and Anaerobic Mixing, Deoxygenation Mixing, RAS/Pre-Anoxic Channel Mixing |

54 |

| Sewatec Pumps | Waste Activated Sludge, Mixed Liquor Fermenter, Drainage | 14 |

| Amacan P Pumps | Mixed Liquor Recycle | 16 |

Comments