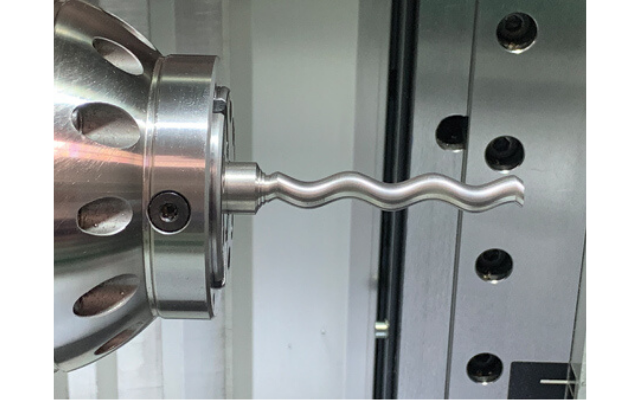

Whirling offers key advantages in cutting threads, screw forms, worms and other items with a pitch. When integrated with other techniques, it creates a rich spectrum of total solutions. Examples include incorporating whirling with milling, grinding and turning, as well as material handling via automated systems.

“As the only U.S. based source of thread whirling tools and machines, Leistritz Machine Tools offers an extensive background in machining solutions for ball screws, EPS worms, extruders and augers,” said a company spokesperson. Leistritz whirling machines, available for both internal and external thread whirling, feature a high degree of automation. Leistritz also offers cost-effective options for demanding manufacturing tasks.

Why Select Whirling?

Why Select Whirling?

According to Leistritz, whirling offers several key advantages, including:

- Possibility to reduce or even eliminate expensive grinding operations

- Improve cycle times-up to 3x faster than milling

- Precise thread profile accuracy, repeatability and surface finish

- Quick tool set-up and workpiece handling

- Eliminate costly disposal of environmentally hazardous cutting fluids and coolants

- Environmentally friendly compared to conventional milling and grinding.

“Leistritz’ easy-to-use tooling system, combined with the benefits of faster cycle times and surface finish quality, offer an economical and cost-effective solution to produce precisely threaded parts,” said the spokesperson.

Whirling of Ball Screws-LWN 160

Whirling of Ball Screws-LWN 160

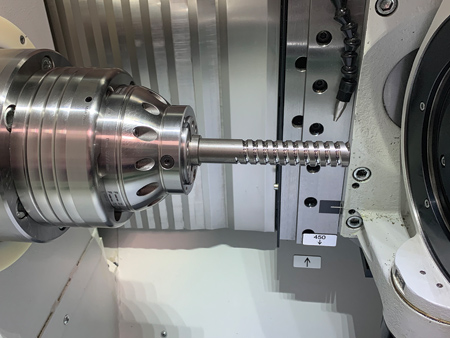

For manufacturers or users of high precision ball screws in the aerospace or automotive industries, as well as industries utilizing linear actuators or linear motion products, Leistritz recommends the LWN 160. “Featuring high profile accuracy in surface finish grinding, along with short set-up and tool changes, the LWN 160 is the most economical, reliable and flexible option for producing high quality ball screws. Our obtainable results can be reached in either hard or soft machining,” said the spokesperson.

The LWN 160, with a high RPM, is designed with centering steady rests with adjustable clamping force. Features include rigid and low vibration clamping, pre-adjustment of cutters and holders with adjusting device of 0.01 mm accuracy, and user-friendly operation and interactive programming. The workpiece diameter for this machine is 10-80 mm with a workpiece length of 6,000 mm.

Internal Whirling of Ball Nuts-LWN 120 IW

Internal Whirling of Ball Nuts-LWN 120 IW

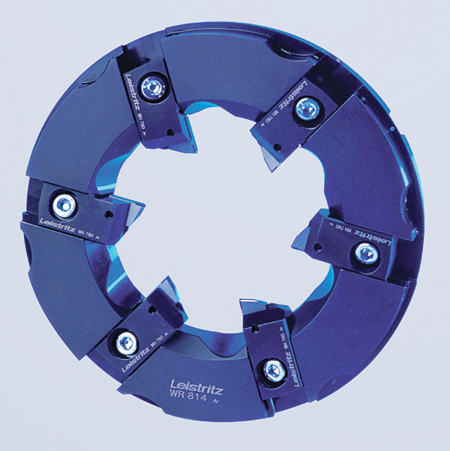

Leistritz offers the LWN 120 IW for finish manufacturing of high precision ball nuts. Leistritz’ hard whirling is used in aerospace, automotive, medical, linear motion and oil and gas industries. “Leistritz accomplishes high profile accuracy with surface finishes equivalent to grinding. This is obtained with shortened cycle times, minimal set-up times and economical tooling solutions,” said the spokesperson. Leistritz machines are custom engineered to individual customer requirements.

The LWN 120 Internal Whirling Machine, designed for high precision, features a direct measuring system in all axes; rigid bed design with preloaded slide guideways; precision workpiece clamping system; and high precision spindle and unit mountings.

“Our whirling process is more environmentally friendly compared to other processes,” said the spokesperson. “Since we dry machine, this process does not require coolant, resulting in less waste and disposal.”

Side Milling & Hobbing-LWN 300 PM

Side Milling & Hobbing-LWN 300 PM

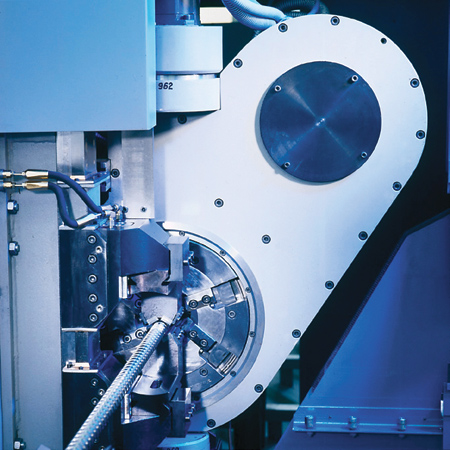

Leistritz’ LWN 300 PM (Power Mill), its newest technology, offers a solution for side milling and hobbing on one machine. “We are the only manufacturer that can mill and hob on a single machine,” said the spokesperson. “The milling cutters are arbor mounted to a O50 mm spindle with an outboard support by a counter bearing to achieve high rigidity. This superior support produces the best surface finishes and a high tool life, ensuring rigidity while maintaining fast tool changeover times. Further, the Power Mill has a continuous diagonal hob shift that utilizes the entire hob face during the cutting of a rotor to evenly distribute tool wear. A complete rotor can be hobbed without the frequent stops for measuring or the exchange of inserts.”

The machine offers easy conversion of existing programs to the coordinate system of the LWN 300 PM. All machine axes are CNC controlled, offering automatic determination of machining height of steady rests.

“Whirling and peeling are little known technologies that some manufacturers have heard of, but may not know exactly how they work or how these technologies can benefit their operation,” said Attila B. Catto, President. “Learning how these technologies work opens up a tremendous number of opportunities for manufacturers to reduce cost and increase production. The implementation of these technologies to the manufacturing process also decreases costs in areas that most people assume are just part of doing business. Imagine having the opportunity to eliminate all environmental costs associated with the production of your components by eliminating disposal of sludge created by grinding. Imagine eliminating costs associated with the removal of swarf that has been drenched in cutting fluid and the use of cleaning solutions necessary to cleaning parts. All of these expensive costs can be eliminated or significantly reduced with the use of our environmentally-friendly whirling machines.”

“Whirling and peeling are little known technologies that some manufacturers have heard of, but may not know exactly how they work or how these technologies can benefit their operation,” said Attila B. Catto, President. “Learning how these technologies work opens up a tremendous number of opportunities for manufacturers to reduce cost and increase production. The implementation of these technologies to the manufacturing process also decreases costs in areas that most people assume are just part of doing business. Imagine having the opportunity to eliminate all environmental costs associated with the production of your components by eliminating disposal of sludge created by grinding. Imagine eliminating costs associated with the removal of swarf that has been drenched in cutting fluid and the use of cleaning solutions necessary to cleaning parts. All of these expensive costs can be eliminated or significantly reduced with the use of our environmentally-friendly whirling machines.”

Comments