Author: Ben Ashe, MDM Inc.

Before I launch into all the reasons why, let me give you the short answer – No! Aquaculture is the practice of ‘farming’ aquatic organisms for food consumption, which is most commonly achieved through land-based Recirculating Aquaculture Systems (RAS). In RAS, pumps are one of the most volatile pieces of equipment. While many swimming pool manufacturers are entering the aquaculture market, it is imperative to point out that many of the products that are advertised to be “Aquaculture Duty” actually lack the features critical to withstand the harsh RAS environment.

We understand how closely the livestock and the life support system are tied to making a profit, so we want to share some information with you about why you should avoid selecting swimming pool pumps for your aquaculture duty applications.

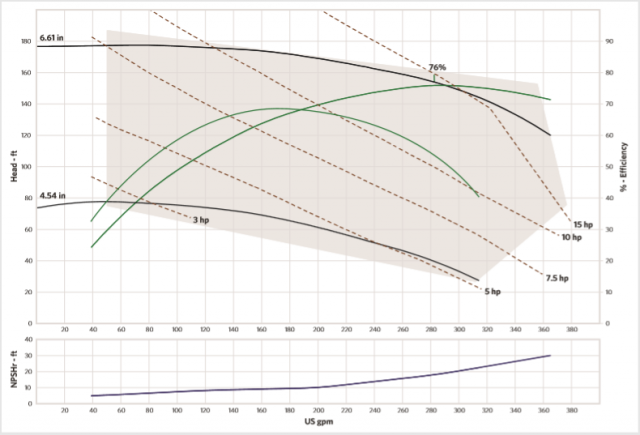

First and foremost, an aquaculture tank is not a swimming pool. Aquaculture tanks are complex life support systems, which is why one should scrutinize pump performance data when specifying a pump for service. Pump efficiency and Brake Horse Power (BHP) are crucial pieces of performance data one needs to make an informed decision. Most pump manufactures outside of the swimming pool industry publish much more data in their performance curves than just flow and head. Given the dynamic performance range of end-suction centrifugal pumps, horse power requirements can differ greatly from one point of the performance curve to another.

Critical Considerations

Motors – While some swimming pool pump manufacturers may offer TEFC motors, others are opting to use Open Drip Proof (ODP) motors, as they are more readily available and are often sourced at lower prices. ODP motors simply don’t stand up to the harsh, corrosive conditions of RAS the way a Totally Enclosed Fan Cooled (TEFC) motor does. With the ODP motor shell exposed to atmospheric conditions, the critical parts of the motor are exposed to rapid corrosion. This is an example of how focusing on lower ‘acquisition cost’ during the selection process can create higher operating expenditures over the long run. Be aware of total cost when selecting your pumps!

Seals – Standard swimming pool seals are designed for simple chlorinated water circulation. Their materials of construction do not support particulates or other corrosive chemicals, and their duty cycle is not as demanding as an aquaculture duty pump. Seals found in swimming pool pumps are not configured for seal flushing, which is a feature that is a ‘must-have’ for removing particulates from seal faces during operation. In aquaculture applications involving salt water, rapid corrosion occurs on seal bodies that are made of brass or 18/8 stainless steel. Also, leaching alloys from corroding metals in salt water systems are toxic to invertebrates, crustaceans, and some mammals. To sum up, seal construction is incredibly important when considering the pumping equipment you install in your aquaculture application – seal failure can lead to pump failure, and pump failure can be catastrophic for your business.

VFDs – Swimming pool pump manufacturers may explain that their variable frequency drive technology provides a constant flow or a speed setting option that will help the pump maintain a consistent flow. With the dynamic TDH or system curve characteristics of most RAS systems, these speed settings would be impossible to maintain flow – unless the system was sized to one of the specific speed settings or a flow meter or pressure transducer is utilized in connection with the VFD. Swimming pool pump manufacturers typically supply their variable speed pumps with a proprietary Input/output signal technology that limits the end user to one option of peripheral fluid system devices, i.e. their branded products, which tends to make things very hard for the end user. It is better to specify VFD units with multiple I/O options that are NOT proprietary and have an abundant amount of features that equip the end user for success in RAS.

If you have any more questions about how to select a pump, contact me to ask as many questions as you like – but for goodness sake, don’t put a pool pump into an aquaculture tank!

About MDM, Inc.

Multi-Duti Manufacturing, Inc. (MDM) has intensely cultivated its SEQUENCE® ADVANCE, and Genesys® brand names since 1978. The names have come to mean high quality and innovation at a reasonable price within several pump market segments; Industrial, Commercial and Consumer.. Learn more at www.mdminc.com.

Comments