Seal failures are a way of life to the mechanical world. There are vast reasons why seals fail. There are many types of seals in the market place. My focus with this article is why I would select a bearing isolator over a rotating lip seal.

First things first, if we are assuming installation are correct, why are the lip seals failing? Generally speaking the lip seals fail due to; hardening, scarring, swelling, cracking, or grooving. What causes these failures? Insufficient lubrication, heat, contaminants, or movement are some of the causes but not all. You will want to select bearing isolators that are made out of blended materials consisting of a PTFE. This will handle chemicals, temperature, and fluid absorption enabling seals to run dry. Second, you want a design that handles movement and is bi- directional. Third, select a two piece seal that is unitized thus enabling the seal to rotate with the shaft preventing grooving of the shaft. These above components when combined will address your sealing concerns.

In choosing bearing isolators you first need to know if the system needs to breathe or be hermetically sealed. The answers to the two questions will determine the flow chart in selecting the isolator. With the breathable seal you have a non-contacting design with virtually no torque consumption. Also, this will not cause wear on the shaft. The breathable seal design has fewer components and offers ease of installation. This design is the seal of choice when axial movement is a concern. Unlike lip seals, when speed and lack of lubrication are an issue, this design is the solution to embrace. When application requires the system to be totally enclosed or is sensitive to atmospheric surroundings you should be using a contacting seal. This design will enable you to close loop within the system. You may want to choose a check valve breathing system (desiccant filter) along with contacting bearing isolators. These total packages enable the moisture to be pulled from the system and do not allow atmospheric conditions to attack the internal mechanics.

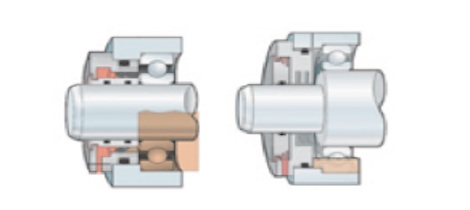

When selecting a contacting bearing isolator you need to select a material that has chemical resistance (PTFE) as well as a graphite blended material which enables better coefficient of friction. There are isolators in the market place that meet these must haves. Remember, unlike lip seals when you are a high volume user, isolators do not require tooling. A machined product almost always retrofits into the same housings and bores. So next time you think that a lip seal is not meeting your requirements or you want to get into the 21st century, choose isolators. Two samples shown below are: 1) Left- contacting and 2) Right- breathable.

For more information: http://www.gaskets-seals.com/products/bearing-isolators/

Comments