Operating equipment in the process industries can be fraught with dangers. Specifically, rubber expansion joints used at high temperatures or improperly installed, and operating pumps away from the best efficiency point (BEP), can cause wear, failure, and extended downtime in operation. One common issue with rotating equipment is vibration, and one way to avoid vibration is to use expansion joints and use them properly.

In addition, piping systems require flexibility, according to the Fluid Sealing Association (FSA). Inadequate flexibility and vibration from fluid-borne noise can lead to wide-scale damage, and expose personnel to the risk of injury.

Rubber expansion joints are flexible connectors fabricated of natural or synthetic oil-based elastomers with fabric reinforcement. Some typical materials used in their construction include:

- Ethylene propylene diene monomer (EPDM)

- Neoprene

- Chlorobutyl

- Hypalon

These materials usually combine with polyester or nylon and wire reinforcing. These connectors are particularly suited to combat the fluid noise that is common with rotating machinery.

Rubber expansion joints are known for their durability and can withstand extreme environments. Therefore, they are most common in harsh applications and those that carry heavy solids such as:

- Chemical processing

- Oil & Gas

- Power Generation

- Pulp & Paper

- Water/Wastewater

- Mining

- Steel mills

- HVAC/building services

When choosing a rubber expansion joint, there are numerous factors to consider. Purchasers should understand these elements of a system in order to select the best joint for the particular application.

- Size by overall length is required.

- What is the operating temperature?

- What is the viscosity of the pumped fluid?

- Are there solids in the fluid?

- What is the pressure?

- What is the estimated movement of the system?

- What is the footprint of the space?

- Is the elastomer used in the joint chemically compatible with the process fluid?

- What is the total cost of ownership?

Extending equipment life

Operators are continually working to extend the life of pump system equipment. There are numerous actions to take when working for a longer and more reliable life cycle.

To start, check the piping alignment. FSA recommends that misalignment should not exceed 1/8 inch at the time of initial installation. For the installation, remember a systematic approach ensures that everything is set to go and operate well from the start. Offset installation puts a system at an automatic disadvantage, creating hazards for equipment and/or people. In general, during any installation, remember that every system is different and should be approached with that in mind.

Take every step necessary to install while eliminating vibration and meeting the guidelines for alignment.

Maintenance

The best advice for maintaining equipment is to follow the manufacturer’s recommended maintenance schedule. The

manufacturer’s manual for a product will supply information on installation, operation and maintenance. The manual will contain all of the information needed to care for that piece of equipment. In the pumps industry, it is all too common for end users to ignore the manual. If saving money and extending equipment life is a goal, the manual should be central to the facility’s operations.

During regular maintenance inspections, visually inspect each connector cover for cracking and hardness. They can pose a particular problem if the footprint of the system is overly reduced. Foundations are another concern because they can settle over time, causing misalignment. Alignment and wear are important indicators of system health and adverse affects of the condition of the connector in question.

Troubleshooting

Troubleshoot failure in the same way you approach installation— remembering that each system and each application are different and should be treated as such. Verify if connector is operating within parameter to which it has been designed. Running a system that has a higher temperature or pressure than it is designed for can be the cause of failure of expansion joints and other components.

Here are some things to check when troubleshooting wear and failure, according to the FSA:

Anchoring. Solid anchoring is required wherever the pipeline changes direction. Expansion joints should be as close as possible to the anchors. If the sites are not properly anchored, control rods should be used. Pipe support is also important, because it ensures that the joints are not carrying any pipeline weight.

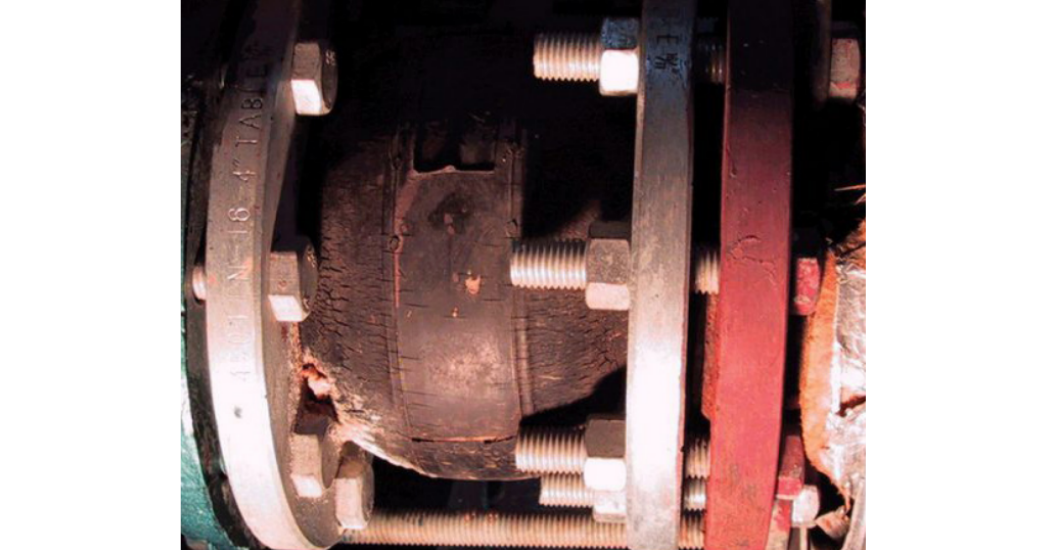

Blisters and cracks. The most common sign of rubber expansion joint fatigue is surface cracking. This on its own may not be serious, but if the inner fabric is exposed, the joint should most likely be replaced, according to industry best practices. Like cracks, some blisters or deformations may be merely cosmetic damage. If the deformities include ply separation delamination in the tube, the joints should be replaced.

Leaks. Before taking action (in repairing or replacing), the source of the leakage should be determined. If leakage or weeping is from any surface of the expansion joint, except where flanges meet, the joint should be replaced. Flange leaks can occur at retaining ring splits. The use of a flat washer at the splits is commonplace to mitigate leakage at these points. With a flange leak, bolts should be tightened. If the leak persists, FSA says, turn off the system pressure, loosen all flange bolts and then retighten them in stages by alternating around the flange.

Maintenance

The best advice for maintaining equipment is to follow the manufacturer’s recommended maintenance schedule. The

manufacturer’s manual for a product will supply information on installation, operation and maintenance. The manual will contain all of the information needed to care for that piece of equipment. In the pumps industry, it is all too common for end users to ignore the manual. If saving money and extending equipment life is a goal, the manual should be central to the facility’s operations.

During regular maintenance inspections, visually inspect each connector cover for cracking and hardness. They can pose a particular problem if the footprint of the system is overly reduced. Foundations are another concern because they can settle over time, causing misalignment. Alignment and wear are important indicators of system health and adverse affects of the condition of the connector in question.

Safety Practices

Expansion joints may transport hazardous materials. Precautions should be taken to protect personnel in the event of leakage or splash. Rubber joints should not be installed in areas where inspection is impossible. Make sure proper drainage is available in the event of leakage when operating personnel are not available. Always wear the appropriate personal protective equipment (PPE) when working on any machinery.

Extreme corrosion. Extreme corrosion is never a good sign. And, despite their design to withstand corrosive materials and abrasion, it can occur over time. If corrosion is present at the joint hardware, it should probably be replaced. Internal degradation to connector is more difficult to spot.

Manufacturers often recommend that facilities keep spare rubber expansion joints on hand for replacements when they are needed—especially for critical pumping applications. Changing them out on a regular maintenance schedule is also advised.

Conclusion

The right expansion joints—when installed and cared for correctly—can, on average (when taking into account all applications), provide an average of 7 to 10 years of service life in many industrial applications. Detailed installation and strictly following the OEM directions for maintenance are imperative to gaining longer system life.

Comments