Low-cost components like check valves can make a big difference to an important installation if the wrong specification or choices are made. Make sure you have the right check valves for your application.

The duckbill valve was inspired by nature. It is a simple check or one-way valve that is formed from a flexible material such as rubber or some other elastic material. Typically, the two halves form a beak-like appendage that allows a fluid to flow easily in one direction. A key characteristic of the duckbill check valve is that it requires no intervention to open or close and operates as a result of a pressure differential across the valve – the pressure from a liquid pushes the two halves apart allowing the fluid to pass through. Conversely, the design of the duckbill valve is such that any flow that moves in the opposite direction causes the two halves to close together. This prevents the passage of any liquid and generally the higher the reverse pressure the tighter the valve closure. While commercial and industrial versions of the duckbill valve typically comprise of two elements, in nature three section types are also found, the mitral valve of the human heart for example closely resembles a rubber duckbill valve.

One-way valves are found in countless applications where they prevent reverse flows. A particularly important function in many fluid-flow applications, reverse flows can lead to water hammer. This is a dramatic phenomenon in which a regular series of extremely powerful pressure surges can rupture connected pipework, valves, and other infrastructure. Even if a catastrophic failure does not occur, water hammer can critically damage any connected equipment through fatigue. As a result, considerable effort is applied to prevent its occurrence. One of the simplest methods is by installing suitable one-way valves at appropriate locations in the system.

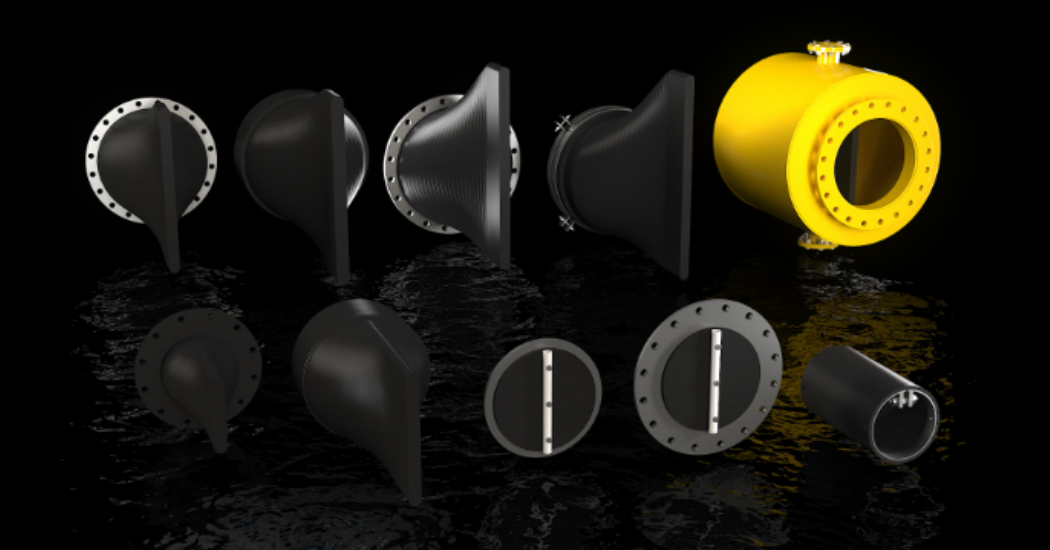

There are, of course, several kinds of one-way valves. While all are suitable for the prevention of reverse flow, each design has benefits and disadvantages. However, many represent several challenges due to their relative complexity, an issue that is not seen with the extremely simple duckbill design. Duckbill valves, formed from rubber of similar material, are not susceptible to corrosion and do not experience mechanical wear. Therefore, although all such valves should be replaced periodically, duckbill valves typically benefit from excellent reliability and extreme longevity.

Comparing check valves

While there are alternatives to flexible duckbill check valve designs, their benefits and drawbacks should be considered. They may suffer from mechanical issues associated with age-related wear and corrosion for example.

- Swing or flap check valves contain a disc, often made of metal, which pivots on a hinge or trunnion in the valve body and can thus block the passage of fluid to prevent reverse flow. Large diameter or high flow applications commonly use swing-type check valves. However, debris such as scale can prevent the disc from seating correctly or prevent the valve from operating. Damage from erosion or corrosion to the disc or seat can also impede closure and result in leakage and reverse flow.

- Ball and spring check valves feature a ball rather than a flap but the principals of failure are similar. Damage to the profile of the valve seat, sediment or other debris can all impact on the full closure of a valve and thus risks allowing reverse flow.

- Diaphragm check valves are like the duckbill design in that they feature a flexible rubber or elastomer component. Suitable for small-bore and low-pressure applications, in use flow pressure pushes against the diaphragm to either open or close the valve depending on the type. However, if a viscous liquid is used this can affect the function of the valve as can damage to the valve seat or debris which may prevent the diaphragm correctly seating.

Where to install a check valve

Almost every fluid flow or pumping environment features check valves, often there are many such valves in a single installation. Along with obvious sectors such as chemicals, petroleum refining, pulp and paper, food and drink processing, industrial, marine and mining, areas such as pumps, pipelines, power generation, HVAC, and sectors like water and wastewater treatment are also heavily dependent on check valves. In power generation applications, for example, high-performance check valves are needed which can handle the pressures and temperatures that are typical of the thermal generation process.

Properly specified check valves are also able to prevent flooding and control back pressure within water and wastewater treatment plants and outfalls and eliminate standing water and all its obvious health hazards. Check valves are used in all stormwater and wastewater systems and are often placed in series in water systems, for instance, to prevent any backflow of wastewater into clean water supply pipelines (CSO’s). For a more detailed explanation of duckbill check valves in stormwater applications see checking the stormwater backflow challenge.

Suitably specified and constructed from appropriate materials, duckbill valves may remain fully serviceable for some 30 years, even as long as 50 years. This compares favorably with typical metal or plastic mechanical check valves that would usually require replacement after less than a decade of service. Check valves are certainly a low-cost component and are often poorly considered in plant specifications as a result. However, given this is a high-risk approach it is clearly beneficial if a thorough review process is implemented to specify the check valves that are deployed in any specific application.

Choosing a check valve

Choosing the right check valve for a particular application depends on several key characteristics. Corrosive materials, abrasive suspended solids and debris can cause flap and swing check valves to rust, bind or seize for instance. Therefore, it is important to select the correct type of valve to ensure that the materials used can manage the fluid concerned. In addition, when exposed to high temperatures some check valve materials can wear and become inoperable. They must be appropriately specified to manage the appropriate temperature range. The fire-retardant elastomeric construction of duckbill valves confers excellent resistance to biological contamination such as barnacles and algae, for example, as well as good abrasive resistance and with nothing to rust or degrade. With the properly specified elastomer, flexible check valves also present good corrosion resistance to almost any fluid and have an operating temperature range from -65 to +250 degrees F.

Check valves are also usually specified in relation to the maximum possible flow rate and therefore on the largest valve flow coefficient (Cv). However, check valves are passive flow devices that rely on flow velocity and pressure to open. Consequently, under more typical operating conditions a check valve specified for peak flow will only partially open during normal operations. Where such a valve is only partially open, flow resistance can increase and the component may experience excessive valve futter or chatter and premature wear. When selecting an appropriate check valve, sizing should be carefully considered to eliminate or reduce the possibility of premature wear and failure.

Other factors to consider when selecting a check valve include valve pressure rating, the line size, if the installation is horizontal or vertical, the dimensions and connection type, maximum leakage rate and pressure drop, as well as any special requirements. Another factor that should also be evaluated is the need for maintenance. Unlike duck-bill check valves, mechanical disc and ball valves can be expensive and difficult to maintain. As they age mechanical check valves deteriorate and may vibrate or emit noises, components can even fail and be lost from the valve and into the connected pipework.

With zero maintenance requirements, high durability, and good reliability, rubber duck-bill check valves are widely considered a good choice in many applications. Nonetheless, an in-depth evaluation should consider all of these factors in determining the most appropriate check valve to specify. It is also important to ensure that once the correct type of valve is chosen it is assembled, installed, and maintained properly if water hammer, reverse flow, leakage, or damage are to be avoided.

Proco Products are leading check valve manufacturers. See Proco’s range of rubber check valves here.

Comments